The Different Types of Power Tools Every DIYer Wishes For

Power Tools – the very words are enough to make any DIY enthusiast’s heart skip a beat. The power of these tools is amazing. If you’ve seen perfectly cut wood or driven screws effortlessly, then you already understand their power. But what makes power tools fascinating is how many different kinds there are. There is a whole universe of these amazing machines available, each one made for a specific job. For example, you can use a jigsaw to create fine details and a hammer drill to tackle concrete walls.

Let’s explore the many shapes, sizes, and functions of power tools on this journey. Whether you’re a seasoned pro or just dipping your toes into the sea of DIY, there’s something here for you. It’s time to put your hand tools away, this power equipment will take you to the next level. If you’ve ever been curious about the various power tools you can use, get ready to be amazed. Let’s dive in and discover the incredible world of power tools together!

Key Takeaways

- Power drills are versatile tools that can be used for drilling holes and driving screws. They are portable and convenient for projects that require mobility or tight spaces.

- Hammer drills are ideal for drilling into tough materials like concrete. They combine drilling and hammering action for high impact and are widely used in construction projects.

- Impact drivers provide high torque and rapid rotational force, making them perfect for driving screws and bolts into tough materials. They are versatile tools for DIY enthusiasts and professional contractors.

- Power saws, such as circular saws and reciprocating saws, are essential tools for woodworking projects. They can cut through a wide range of materials and are suitable for various tasks like demolition work and making precise and straight cuts.

Different Types of Power Tools: The Essential Power Tool List

Many types of power tools fall into the below categories:

- Drills, Drivers, Fasteners

- Saws and Cutting Tools

- Sanders

- Air Tools

- Woodworking Tools

- Metalworking Tools

In terms of electrical power tools, you typically have a choice between corded and cordless options.

Cordless vs. Corded Power Tools

To determine which type of power tool is best for you, consider whether you prefer the convenience of cordless or the consistent power of corded tools.

Cordless power tools, such as drills and saws, offer the advantage of mobility and flexibility. They are powered by rechargeable batteries, allowing you to work in areas without access to electrical outlets.

On the other hand, corded power tools, like electric drills and saws, provide a constant and uninterrupted power supply. This is particularly beneficial for heavy-duty tasks that require sustained power. Corded tools are also generally more powerful than their cordless counterparts. However, they do require access to an electrical outlet and can be less portable.

Ultimately, the choice between cordless and corded power tools depends on the specific needs of your projects and the level of convenience and power you require.

Power Drills, Power Ratchet Sets, Impact Wrenches and Drivers

Standard Drill

A drill is a versatile handheld tool used for drilling holes and driving screws into various materials. It is powered by an electric motor and operates by rotating a drill bit or screwdriver bit, providing controlled and efficient drilling and fastening capabilities.

The main uses of a power drill are:

Drilling Holes: Drills are primarily designed for drilling holes in materials like wood, metal, plastic, and masonry. They can create holes of different sizes, making them valuable for tasks such as installing shelves, assembling furniture, making holes for wiring and plumbing, and various construction projects.

Driving Screws and Fasteners: Drills equipped with screwdriver bits or drivers are used for driving screws and fasteners into various materials. They offer speed and efficiency when assembling furniture, hanging shelves, attaching brackets, and performing general maintenance tasks.

Mixing and Stirring: Some drills can be fitted with mixing attachments, such as paddle mixers, for stirring and mixing various materials. This is particularly useful in construction and home improvement projects, where mixing paint, drywall compound, grout, and other materials is necessary.

Hammer Drill

A hammer drill is a versatile and powerful handheld or stationary tool designed for drilling holes in hard materials, such as concrete, brick, and stone. It features a hammering mechanism that creates rapid, axial impacts in addition to the rotary drilling motion, allowing it to tackle tough drilling tasks with ease.

The main uses of a hammer drill are:

Concrete Drilling: Hammer drills are commonly used for drilling holes in concrete, masonry, and other hard building materials. Their ability to deliver both rotational force and percussive impacts allows them to penetrate tough surfaces efficiently. This makes them invaluable for tasks like installing anchor bolts, wall anchors, and concrete screws, as well as creating openings for electrical conduit and plumbing in concrete structures.

Masonry Work: Hammer drills are versatile tools for masonry work, including brickwork and stone masonry. They are used for drilling holes for dowels, anchors, and fasteners, as well as for creating passageways for pipes and cables in masonry walls and structures.

Tile and Ceramics: Hammer drills equipped with specialized tile or ceramic chisels or bits are suitable for drilling holes and removing tiles and ceramic surfaces. The percussive action helps prevent cracking and chipping, making them valuable tools for installing fixtures, mounting shelves, and running plumbing or electrical lines through tiled walls or floors.

Impact Driver

An impact driver is a compact and high-torque power tool designed for driving screws and fasteners, as well as drilling holes in various materials. It operates by delivering rapid, rotational bursts of force in a rotational direction, making it exceptionally efficient at tasks involving fastening or drilling.

The main uses of an impact driver are:

Driving Screws and Fasteners: Impact drivers are commonly used for driving screws and fasteners into various materials, including wood, metal, and plastic. Their high torque output and rotational impact mechanism allow them to effortlessly sink screws, even in dense or hard materials, while reducing the risk of stripping the screw head or damaging the workpiece. This makes them invaluable for tasks like framing, decking, assembling furniture, and installing cabinetry.

Loosening Stubborn Fasteners: Impact drivers are equally effective at loosening tight or stubborn screws and fasteners. The rapid, rotational force they deliver helps break free rusted, corroded, or over-tightened fasteners. This capability is especially valuable in automotive repair and maintenance, as well as in construction and mechanical work, where disassembly and removal of fasteners are common tasks.

Drilling Holes: Many modern impact drivers come equipped with a chuck that can accept drill bits. This allows them to function as both impact drivers and drills. This dual functionality reduces the need to switch between tools during a project, enhancing efficiency.

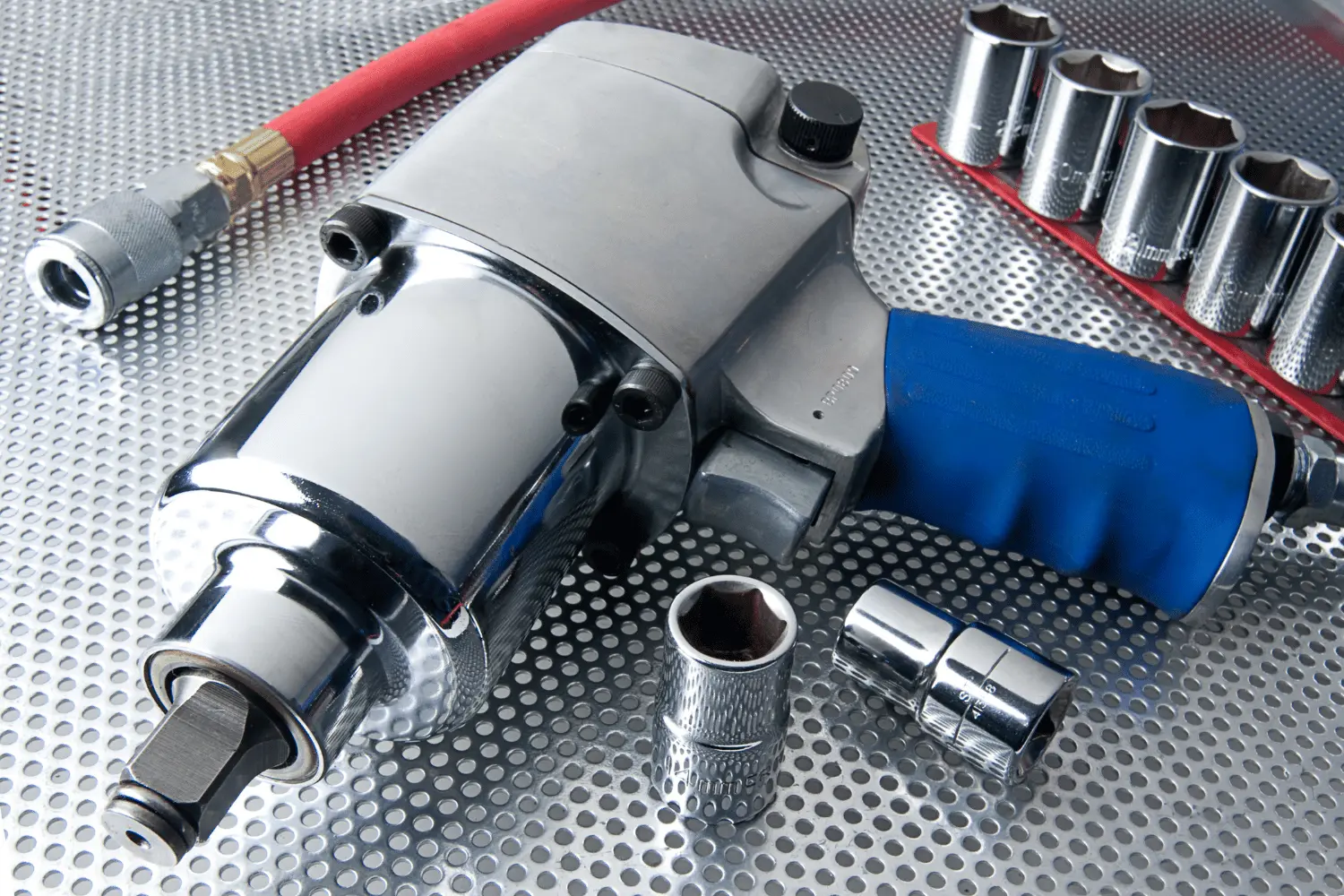

Impact Wrench

An impact wrench, also known as an impact gun or air wrench, is a powerful handheld or pneumatic tool designed for fastening and loosening nuts, bolts, and other fasteners with high torque and efficiency. It operates by delivering short, intense bursts of rotational force to the fastener, making it particularly effective in heavy-duty applications.

The main uses of an impact wrench are:

Automotive and Mechanical Work: Impact wrenches are widely used in automotive repair and maintenance, as well as mechanical and industrial settings. They are invaluable for tasks such as removing and installing lug nuts on wheels, tightening and loosening engine and suspension components, and assembling machinery and equipment.

Construction and Building Trades: In the construction industry, impact wrenches are employed for securing structural components and fasteners in buildings, bridges, and other infrastructure projects. They are used to drive large bolts and anchor bolts into concrete and steel, making them indispensable tools for steel erection, formwork assembly, and concrete construction.

Heavy Equipment Maintenance: Impact wrenches find applications in industries that involve heavy machinery and equipment, including agriculture, mining, and manufacturing. They are used to service and maintain heavy equipment, such as tractors, bulldozers, and mining trucks, by fastening and loosening the substantial bolts and nuts that hold these machines together.

Power Ratchet

A power ratchet, also known as a cordless ratchet or electric ratchet, is a handheld power tool designed for fastening and loosening bolts and nuts with speed and efficiency. It operates by utilizing a motorized mechanism that rapidly turns a socket or bit to tighten or loosen fasteners. Power ratchets are commonly used in automotive maintenance and repair but have applications in various industries.

The main uses of a power ratchet are:

Automotive Repair and Maintenance: Power ratchets are indispensable tools in automotive garages and workshops. They are used for quickly and efficiently removing and installing nuts and bolts in various automotive components, such as wheels, engine parts, suspension systems, and brake systems. Power ratchets are especially valuable for tasks that involve multiple fasteners, saving mechanics and technicians considerable time and effort.

Construction and Building Trades: Power ratchets find applications in construction and building trades, particularly in tasks involving structural assemblies and fastening. Contractors and builders use them for securing bolts in steel framing, scaffolding, and other construction elements.

General Maintenance and Assembly: Beyond automotive and construction work, power ratchets are versatile tools for general maintenance and assembly tasks in various industries. They are commonly used for assembling and disassembling furniture, appliances, machinery, and equipment.

Power Saws: Jigsaws, Circular Saws and More

Jigsaw

A jigsaw is a versatile and handheld power tool designed for making intricate and curved cuts in various materials, including wood, metal, plastic, and even ceramics. It features a narrow, reciprocating blade that moves up and down rapidly to cut through the material. Jigsaws are known for their maneuverability and precision, making them valuable tools for a wide range of cutting tasks.

The main uses of a jigsaw are:

Curved and Intricate Cuts: Jigsaws excel at making curved and intricate cuts that other saws, such as circular saws or reciprocating saws, would struggle to achieve. Woodworkers and DIY enthusiasts use jigsaws to create decorative scrollwork, intricate patterns, and complex shapes in materials like wood and plastic. This makes them essential tools for tasks like crafting wooden ornaments, making jigsaw puzzles, and cutting out detailed designs in woodworking projects.

Cutting Holes and Openings: Jigsaws are commonly used for cutting holes and openings in various materials, such as countertops, cabinets, doors, and drywall. They are valuable tools for tasks like creating sink cutouts in kitchen countertops, making openings for electrical outlets and switches, and installing ventilation ducts.

Trimming and Custom Fitting: Jigsaws are employed for trimming and custom fitting materials to specific dimensions. Whether it’s trimming excess material from a piece of laminate flooring, customizing the fit of shelving units, or cutting molding to size, jigsaws provide the precision and control needed to achieve accurate cuts, especially in confined or irregular spaces.

Circular Saw

A circular saw is a versatile and portable power tool with a circular blade that rotates rapidly to cut through various materials, including wood, metal, plastic, and more. It is one of the most common and essential tools in construction, woodworking, and home improvement projects.

The main uses of a circular saw are:

Straight Cuts: Circular saws excel at making straight cuts in a wide range of materials. They are often used for cutting dimensional lumber, plywood, OSB (oriented strand board), and other sheet goods to size. The adjustable depth and angle settings on circular saws allow for precise and controlled straight cuts, making them indispensable for framing, decking, and general carpentry work.

Crosscuts and Bevel Cuts: Circular saws can make crosscuts, which involve cutting a workpiece across its width, and bevel cuts, which are angled cuts. With the appropriate adjustment, circular saws can create miter cuts and bevel cuts for applications such as making angled joints, trimming door bottoms, and creating decorative edges.

Rip Cuts with a Guide: While circular saws are primarily used to cut material in a straight line, they can also be used to perform rip cuts, which involve cutting along the length of a material. This is typically done with the help of a straight edge or guide to ensure accuracy.

Miter Saw

A miter saw, also known as a chop saw or miter box, is a specialized power tool used for making accurate and precise angled cuts in various materials, primarily wood, but also plastics and certain metals. It is a stationary tool that features a circular saw blade mounted on a pivoting arm, allowing the user to make precise crosscuts and miter cuts at specific angles.

The main uses of a miter saw are:

- Miter Cuts: A miter saw is primarily designed for making miter cuts, which are angled cuts made across the width of a workpiece. These cuts are commonly used in woodworking and carpentry for creating angled joints, such as picture frames, crown molding, and baseboards. Miter saws are equipped with a swiveling base that allows users to set and lock the desired angle, ensuring precise and consistent miter cuts.

- Crosscuts: Miter saws are excellent for making accurate crosscuts, which are straight cuts made across the length of a workpiece. They are often used to cut boards and panels to specific lengths with precision. This makes them invaluable for framing, building furniture, and various other woodworking projects where accurate sizing is crucial.

- Bevel Cuts: Many miter saws come with a feature that allows for bevel cuts, which are angled cuts made through the thickness of a workpiece. This capability is particularly useful for creating compound miter cuts, where both the miter angle and bevel angle are adjusted simultaneously. Bevel cuts are frequently used in tasks such as creating complex joinery for furniture, trimming and shaping edges, and achieving various design elements in woodworking.

Reciprocating Saw

A reciprocating saw, also known as a recip saw or sawzall (a trademarked term by Milwaukee Electric Tool), is a versatile and powerful handheld cutting tool designed for a wide range of demolition, construction, and renovation tasks. It operates by using a reciprocating motion to move a blade back and forth, allowing for efficient cutting in various materials.

The main uses of a reciprocating saw are:

Demolition and Material Removal: Reciprocating saws are commonly used for demolition work, making them valuable tools for construction professionals and DIY enthusiasts. They can quickly and effectively cut through a variety of materials, including wood, plastic, metal, drywall, and even masonry. Common demolition tasks include removing walls, cutting through nails and screws, dismantling old structures, and clearing away damaged or unwanted materials.

Pruning and Tree Trimming: Reciprocating saws equipped with specialized pruning blades are ideal for outdoor tasks such as pruning trees, cutting branches, and trimming shrubs.

Pipe and Metal Cutting: Reciprocating saws are used for cutting metal pipes, tubing, and metal conduit. They are valuable tools in plumbing and electrical work for making precise cuts in tight spaces.

Track Saw

A track saw, also known as a plunge saw, is a precision cutting tool designed for making straight and accurate cuts in various materials, particularly wood and sheet goods. It consists of a circular saw mounted on a guided track or rail system, which provides stability and ensures the saw follows a predetermined cutting path. Track saws are popular among professionals and DIY enthusiasts for their ability to create clean and precise cuts.

The main uses of a track saw are:

Straight Line Rip Cuts: Track saws excel at making long, perfectly straight rip cuts in a wide range of materials. Whether cutting solid wood, plywood, MDF, or other sheet goods, the guided track ensures that the saw moves along a precise path, resulting in smooth and accurate cuts. This capability is especially useful for breaking down large sheet materials into more manageable sizes, such as when preparing plywood for cabinet construction or paneling for wall installations.

Plunge Cuts: Track saws can make plunge cuts, which involve starting the cut in the middle of a workpiece without the need for an entry hole or edge. This is valuable for tasks such as creating openings for sinks, countertops, and electrical outlets in various construction and remodeling projects.

Bevel Cuts and Angle Cuts: Track saws are versatile tools that can make bevel cuts and angled cuts when needed. By adjusting the saw’s cutting depth and bevel angle, woodworkers and tradespeople can create beveled edges, chamfers, and angles with precision. This capability is useful in projects that require beveled edges on tabletops, cabinets, or other components.

Band Saw

A band saw is a versatile and powerful woodworking and metalworking tool consisting of a continuous looped blade with teeth that rotate around two large wheels. The workpiece is fed into the blade, allowing for a wide range of cutting operations. Band saws come in various sizes, from small benchtop models to large industrial machines.

The main uses of a band saw are:

Curved and Irregular Shape Cutting: Band saws are highly efficient at cutting curved and irregular shapes in wood, metal, and other materials. The thin and flexible blade allows for precise control when navigating intricate patterns and tight curves. This makes band saws ideal for tasks like crafting wooden ornaments, creating decorative scrollwork, and shaping metal components.

Resawing and Splitting Stock: Band saws are commonly used for resawing, which involves cutting a thick board into two thinner boards. This is particularly useful for obtaining multiple pieces of veneer from a single board or for creating thin stock for various woodworking applications.

Cutting Straight Lines and Joinery: While band saws are renowned for their curved cutting capabilities, they can also be used for making straight cuts, especially when equipped with a fence or guide. Band saws are employed for cutting straight lines, ripping narrow strips, and performing various joinery cuts, such as tenons and lap joints.

Table Saw

A table saw is a powerful and versatile woodworking tool that consists of a circular saw blade mounted on an arbor and driven by an electric motor. It is typically mounted on a stationary table with a flat work surface and a guide fence to ensure precise and controlled cuts. Table saws are essential tools in woodworking shops and are available in various sizes and configurations, including portable and cabinet-style models.

The main uses of a table saw are:

Rip Cuts: Table saws excel at making long, straight rip cuts along the length of a workpiece. This is accomplished by adjusting the distance between the saw blade and the fence, which determines the width of the cut. Table saws are commonly used for ripping boards to size, such as creating strips of wood for various woodworking projects, cutting sheet goods like plywood and MDF, and creating consistent widths for components like cabinet parts and table legs.

Crosscuts: While table saws are primarily designed for rip cuts, they can also be used for crosscutting wood by using accessories like miter gauges or sleds. Crosscuts involve cutting a workpiece perpendicular to its grain or across its width.

Joinery and Dadoes: Table saws are valuable for creating joinery cuts, such as tenons and dadoes. Tenons are often used for creating strong, interlocking joints, while dadoes are grooves cut into the wood to accommodate shelves, panels, and other components. Table saws equipped with specialized dado blades or dado sets can make these cuts accurately and efficiently, providing precise joinery solutions in projects like cabinets, bookcases, and furniture.

Router

A wood router is a versatile and powerful woodworking tool designed for hollowing out or grooving areas in wood and other materials. It features a high-speed rotating cutting bit, typically with a variety of profiles, that removes material as it moves along the workpiece. Wood routers come in both handheld and table-mounted versions, each suitable for specific applications.

The main uses of a wood router are:

Edge Profiling and Shaping: Wood routers are used for shaping and profiling edges of wooden workpieces. Woodworkers use routers to add decorative edges, profiles, and contours to the edges of wooden boards and panels. The tool can create a wide range of decorative edges, including chamfers, roundovers, ogees, and coves.

Grooving and Dadoing: Routers are employed to cut grooves, dadoes, and rabbets in wood, which are essential for various joinery techniques. Routers can create precise channels and recesses for housing shelves, panels, and other components in woodworking projects like bookshelves, cabinets, and drawers.

Hollowing and Inlay Work: Wood routers are used for hollowing out areas within wooden surfaces, creating intricate inlays, and carving patterns. This is especially useful in artistic and decorative woodworking, where intricate designs or custom inlays are desired on tabletops, doors, and other surfaces.

Biscuit Joiner

A biscuit joiner, also known as a plate joiner, is a specialized woodworking tool designed for creating strong and precise joinery connections in wood. It operates by cutting crescent-shaped slots, often referred to as “biscuit slots,” into the edges of two pieces of wood, which are then joined together using specially designed wooden biscuits and adhesive.

The main uses of a biscuit joiner are:

Edge-to-Edge Joinery: Biscuit joiners are commonly used to create seamless edge-to-edge joints in wood panels, boards, or planks. The tool cuts matching slots in the mating edges of two pieces of wood, and a wooden biscuit is inserted into each slot after applying glue. When the pieces are clamped together, the biscuits swell and create a strong, concealed joint. This technique is often used in tabletops, panels, and wide boards to create a flat and stable surface.

Miter Joints: Biscuit joiners can be employed to enhance the strength and alignment of miter joints, which are typically used in frame construction. By cutting matching biscuit slots in the mitered ends of frame pieces and using biscuits and glue, woodworkers can create strong and well-aligned corner joints, improving the stability and longevity of frames for items like picture frames and cabinets.

T-Joints and Butt Joints: Biscuit joiners are also useful for creating T-joints and butt joints in woodworking projects. T-joints involve joining one piece of wood perpendicularly to another, while butt joints involve connecting two pieces end-to-end.

Angle Grinder

An angle grinder, also known as a disc grinder or side grinder, is a versatile and powerful handheld power tool used in a variety of industries for various cutting, grinding, and polishing tasks. It is characterized by its abrasive grinding disc or cutting wheel, which rotates at high speeds to remove material or achieve specific finishes.

The main uses of an angle grinder are:

Cutting Metal and Masonry: Angle grinders are commonly used for cutting metal and masonry materials. With the appropriate abrasive cutting wheel, they can efficiently cut through steel, iron, aluminum, concrete, stone, and other hard materials. This makes them indispensable in metalworking shops for cutting metal stock, rebar, and pipes, as well as in construction and masonry for tasks like cutting concrete, brick, and tile.

Grinding and Surface Preparation: Angle grinders are employed for grinding and preparing surfaces. They can remove rust, paint, weld slag, and other surface contaminants from metal, making them valuable tools in automotive restoration and metal fabrication. In construction and renovation, angle grinders are used to smooth uneven surfaces, prepare concrete for coatings, and remove imperfections in wood and metal.

Polishing and Finishing: Angle grinders can be equipped with polishing or buffing attachments to achieve a polished or smooth finish on various materials. They are used in automotive detailing to polish car paint, in woodworking to achieve a smooth finish on wooden surfaces, and in metalworking to create a polished finish on metal parts. Angle grinders are also used to shape and polish stone and concrete countertops.

Chainsaw

A chainsaw is a versatile and powerful mechanical tool used for cutting through wood, branches, and other materials by means of a rapidly rotating chain fitted with sharp teeth. Chainsaws come in various sizes, from small handheld models to larger, gas-powered or electric saws, each designed for specific applications.

The main uses of a chainsaw are:

Tree Felling: Chainsaws are widely used for cutting down trees, whether for forestry and timber harvesting operations or for removing dead or unwanted trees in landscaping and construction projects. Chainsaws are capable of efficiently cutting through both small and large trees, making them essential tools for professionals in the forestry and arboriculture industries.

Branch Pruning and Trimming: Landscapers and arborists use chainsaws for pruning and trimming tree branches. Chainsaws allow for precise cutting of branches to maintain the health and aesthetics of trees, remove dead or diseased limbs, and create a safe environment for people and structures beneath.

Lumber Production and Firewood Cutting: Chainsaws are used in small-scale lumber production to cut logs into manageable pieces for further processing. Additionally, they are invaluable for cutting firewood from logs and fallen branches, especially in rural and outdoor settings.

Stationary Power Tools – Electrical Power Tools for Wood and Metalworking

Jointer

A jointer, also known as a surface planer or thickness planer, is a woodworking machine designed for flattening and straightening the faces and edges of rough or uneven lumber. It is a fundamental tool in woodworking shops and is used to prepare wood for further processing and joinery.

The main uses of a jointer are:

Face Jointing: Jointers are primarily used for face jointing, which involves flattening one face of a board to create a perfectly flat and smooth surface. This process provides a reference surface that serves as a starting point for further machining and ensures that the material is flat and even.

Edge Jointing: Jointers are employed to straighten and square one edge of a board, ensuring that it is perfectly straight and at a right angle to the reference face. Edge jointing is essential for creating tight-fitting joints, such as edge-to-edge glue-ups for panels and tabletops.

Thickness Planing: Some jointers can also be used for thickness planing, which involves reducing the thickness of a board by removing material from one side. This capability allows woodworkers to achieve a consistent thickness across multiple boards, ensuring uniformity in projects like paneling and cabinetry.

Planer

A planer is a woodworking machine designed for flattening, smoothing, and dimensioning wooden boards and other materials by removing a controlled amount of material from their surfaces. It plays a fundamental role in woodworking shops and is available in various sizes, from portable hand planers to large industrial planers.

The main uses of a planer are:

Surface Smoothing: Planers are primarily used to achieve a smooth and even surface on rough-sawn lumber or boards with uneven surfaces. They quickly and efficiently remove imperfections, such as knots, ridges, and cupping, resulting in a flat and uniform workpiece. This is essential for producing high-quality finished surfaces in woodworking projects.

Dimensioning and Thicknessing: Planers are used to achieve precise and consistent thicknesses in boards and panels. Woodworkers can feed rough stock through the planer to reduce its thickness to the desired dimensions, ensuring that all components of a project are uniform in size. This is particularly important for tasks like creating panels for doors, tabletops, and cabinets.

Parallel Sides: Planers are employed to create parallel and square sides on boards and panels. This is crucial for achieving tight-fitting joints and ensuring that the edges of components align correctly during assembly. Planers are often used in conjunction with jointers to prepare wood for joinery and construction.

Lathe

A lathe is a versatile machine tool used in various industries, particularly in woodworking and metalworking, for shaping and machining cylindrical workpieces. It operates by rotating the workpiece while a cutting tool is applied to it, allowing for precise shaping, cutting, and drilling operations. Lathes come in various sizes and configurations, from small benchtop models to large industrial machines.

The main uses of a lathe are:

Turning: The primary and most fundamental use of a lathe is turning. It involves rotating a workpiece on the lathe’s spindle while a cutting tool, such as a chisel or gouge, is brought into contact with the material. This process allows for the creation of cylindrical shapes, such as dowels, spindles, shafts, and posts. Wood lathes are commonly used for crafting items like table legs, bowls, and wooden ornaments, while metal lathes are used for machining parts with precision.

Facing: Lathes are used for facing operations, where the cutting tool is used to create flat surfaces on the ends of a cylindrical workpiece. This is important for achieving square and perpendicular surfaces for parts like bearings, bushings, and flanges. Facing is also essential for ensuring that workpiece ends are parallel to each other.

Drilling and Boring: Lathes can be equipped with drilling and boring attachments to create holes and cavities within a workpiece. This is particularly useful for making precision holes, such as those needed for bearings, fasteners, and bushings.

Drill Press

A drill press, also known as a drilling machine or a bench drill, is a stationary machine tool designed for accurately drilling holes in various materials with precision and control. It is a versatile tool commonly found in workshops, metalworking, woodworking, and manufacturing facilities.

The main uses of a drill press are:

Hole Drilling: The primary and most common use of a drill press is for drilling holes in a wide range of materials, including wood, metal, plastic, and composites. The drill press provides excellent control over hole depth, diameter, and accuracy, making it ideal for tasks such as creating holes for fasteners, dowels, bolts, and electrical wiring.

Reaming: A drill press can be used for reaming operations, which involve enlarging existing holes to achieve precise dimensions or to ensure a snug fit for mating parts. Reaming is often employed in metalworking to achieve tight tolerances in machine parts and components.

Counterboring and Countersinking: Drill presses are used to create counterbores and countersinks in workpieces. Counterboring involves creating a recessed area around a hole to accommodate the head of a fastener, while countersinking involves beveling the edge of a hole to allow the fastener head to sit flush with or below the surface of the material.

Air Compressors and Nail Guns

Air Compressor

An air compressor is a mechanical device that converts power, typically from an electric motor or a gasoline engine, into compressed air. This compressed air is stored in a tank and can be released at various pressures to perform a wide range of tasks in various industries and applications. Air compressors are available in different sizes and configurations, from small portable units to large industrial systems.

The main uses of an air compressor are:

Pneumatic Tools: Air compressors power a vast array of pneumatic (air-powered) tools, making them versatile and efficient for tasks in construction, automotive repair, woodworking, metalworking, and more. Common pneumatic tools include air impact wrenches, nail guns, air drills, paint sprayers, sandblasters, and air ratchets.

Inflating Tires and Objects: Air compressors are frequently used for inflating tires, sports equipment (such as basketballs and soccer balls), inflatable toys, and vehicle air suspension systems.

Industrial Processes: Air compressors play a critical role in various industrial applications, such as manufacturing, food processing, pharmaceuticals, and electronics. They are used for tasks like cleaning, drying, conveying materials (pneumatic conveying), and powering pneumatic actuators and control systems in automated machinery.

Nail Guns

Framing Nailer

A framing nailer is a powerful and specialized pneumatic or cordless tool used primarily in construction and carpentry for quickly and securely fastening large framing and structural components. It is designed to drive large, long nails, known as framing nails, into wood and other materials with precision and efficiency.

The main uses of a framing nailer are:

Framing and Structural Work: Framing nailers are essential for framing houses, buildings, and other structures. They are used to attach framing components such as wall studs, floor joists, roof trusses, and headers.

Sheathing and Decking: Framing nailers are used to attach plywood or OSB (oriented strand board) sheathing to the structural frame of a building. This creates a solid, stable surface that forms the basis for siding, roofing, and flooring installations. Framing nailers are also employed in deck construction to fasten deck boards to the underlying joists.

Fencing and Exterior Woodwork: Framing nailers are used in various outdoor construction projects, including building fences, attaching exterior siding, and constructing pergolas, decks, and outdoor structures.

Brad Nailer

A brad nailer is a specialized pneumatic or cordless tool designed for precision fastening of small, thin nails called brads. It is a versatile and essential tool in woodworking and carpentry, known for its ability to create neat, inconspicuous, and secure connections without leaving visible holes or marks on the workpiece.

The main uses of a brad nailer are:

Finish Carpentry: Brad nailers are commonly used in finish carpentry projects, where precision and aesthetics are crucial. They excel at attaching trim, moldings, baseboards, crown molding, and other decorative elements to walls, ceilings, and furniture.

Assembly and Joinery: Brad nailers are valuable for assembling small wooden components and creating tight, hidden joints. They are used in joinery applications like building cabinets, drawers, and picture frames.

Fastening Thin Materials: Brad nailers are ideal for fastening thin or delicate materials like veneer, thin plywood, and delicate trims without causing damage or visible marks. They are also suitable for securing lightweight materials such as cloth, leather, or even some plastics.

Finish Nailer

A finish nailer is a specialized pneumatic or cordless tool designed for driving finish nails into woodworking projects, providing a clean, professional, and secure finish. Finish nails are slightly larger and stronger than brads but still leave minimal visible marks, making them ideal for applications where aesthetics and structural integrity are important.

The main uses of a finish nailer are:

Finish Carpentry: Finish nailers are essential tools for finish carpentry tasks, where precision and appearance matter most. They are used to attach trim, moldings, baseboards, crown molding, wainscoting, and other decorative elements to walls, ceilings, and floors.

Furniture Making: Finish nailers are employed in furniture making to join components such as tabletops, chair frames, cabinet doors, and drawer fronts.

Cabinet Installation: Finish nailers are used to secure cabinets to walls and each other during installation. They provide strong and inconspicuous connections that help cabinets remain stable and level. Additionally, finish nailers are used for attaching trim and decorative elements to cabinets.

Handheld Power Sanders – Belt Sander and More

Belt Sander

A belt sander is a power tool that features a continuous looped sanding belt stretched over two cylindrical drums. It is designed for aggressively removing material from a workpiece, primarily through sanding and smoothing operations. Belt sanders are available in various sizes, including handheld and stationary models, and they are versatile tools commonly used in woodworking and metalworking.

The main uses of a belt sander are:

Material Removal and Shaping: Belt sanders are highly effective at quickly removing excess material from workpieces, making them valuable tools for shaping and sculpting wood, metal, plastic, and other materials. They are used to flatten uneven surfaces, shape curved or beveled edges, and reduce the thickness of materials rapidly.

Surface Smoothing and Finishing: Belt sanders can be used to achieve a smooth and uniform surface finish on various materials. They are particularly useful for removing imperfections, scratches, and old finishes from wood and metal surfaces.

Stock Preparation and Edge Sanding: Belt sanders are employed to prepare stock material, such as rough lumber, for further processing. They quickly remove rough surfaces and mill marks, resulting in clean and flat stock ready for joinery and construction. Additionally, belt sanders can be used for edge sanding, where the edge of a workpiece is smoothly rounded or squared off for specific applications.

Random Orbit Sander

A random orbit sander is a versatile power tool designed for sanding and finishing tasks, known for its ability to provide a smooth and swirl-free surface finish. It operates by simultaneously rotating and oscillating the sanding pad in a random pattern, which reduces the risk of leaving noticeable sanding marks or swirls on the workpiece. Random orbit sanders are available in various sizes, including handheld and palm-sized models.

The main uses of a random orbit sander are:

Sanding Wood Surfaces: Random orbit sanders are commonly used for sanding wood surfaces, including furniture, cabinets, doors, and woodworking projects. They excel at removing old finishes, smoothing rough wood, and preparing surfaces for paint or stain. The random sanding motion helps prevent visible sanding patterns and allows for a consistent and even finish.

Sanding and Refinishing Floors: In floor refinishing applications, larger random orbit floor sanders are used to prepare and refinish hardwood floors. They efficiently remove old finishes, scratches, and imperfections, leaving behind a smooth and uniform surface that can be refinished with a new coat of stain or finish.

Finishing and Polishing: Random orbit sanders can be equipped with fine-grit sandpaper or polishing pads to achieve a polished or buffed finish on various materials, including wood, metal, plastic, and automotive surfaces. They are used for tasks such as restoring the luster of car paint, polishing metal surfaces, or buffing out minor imperfections on woodwork.

Frequently Asked Questions

Are Power Tools Suitable for Beginners or Should They Only Be Used by Professionals?

Power tools can be used by both beginners and professionals. They provide efficiency and precision in various tasks. With proper training and safety precautions, beginners can safely utilize power tools and gain experience over time.

Can Power Tools Be Used for Outdoor Projects or Are They Mainly for Indoor Use?

Power tools can be used for both outdoor and indoor projects. They offer convenience, efficiency, and power to complete various tasks. Whether it’s building a deck or renovating a room, power tools are versatile and reliable.

What Are Some Common Safety Precautions to Take When Using Power Tools?

To ensure your safety when using power tools, always wear protective gear like goggles, gloves, and earplugs. Keep your work area clean and well-lit, and never rush or use a tool if you’re tired or distracted.

Are There Any Power Tools That Are Specifically Designed for Woodworking Projects?

Yes, there are power tools specifically designed for woodworking projects. They include table saws, routers, and jigsaws, among others. These tools are designed to help you cut, shape, and join wood with precision and ease.

How Can I Ensure That My Power Tools Last Longer and Remain in Good Working Condition?

To ensure your power tools last longer and stay in good working condition, perform regular maintenance such as cleaning, lubricating, and checking for any damage. Store them properly and follow the manufacturer’s instructions for usage and safety precautions.