Miter Saw vs Table Saw – Which One is Right For You?

Picture this: you’re in the middle of a woodworking project, and you need to make a series of precise angled cuts for the perfect finish. You have both a miter saw and a table saw at your disposal, but which one should you choose? It’s a common dilemma faced by both beginners and experienced woodworkers alike. In this blog post, we will help you navigate this decision by comparing the capabilities, uses, and other factors that can influence your choice in the “miter saw vs table saw” debate.

By the end of this article, you’ll have a better understanding of the advantages and disadvantages of these two essential power tools in the context of miter saw vs table saw. With this knowledge, you’ll be able to make an informed decision on which tool is right for your specific woodworking projects, ensuring the best possible results.

Key Takeaways

- Miter saws are renowned for their accuracy and precision, while table saws offer greater versatility with larger workpieces.

- Evaluate the needs of your project to choose between miter saws or table saws from popular brands such as Bosch, Metabo HPT, Delta, DeWalt and Makita.

- Follow safety guidelines when using either tool to reduce risk of injury.

Understanding Miter Saws

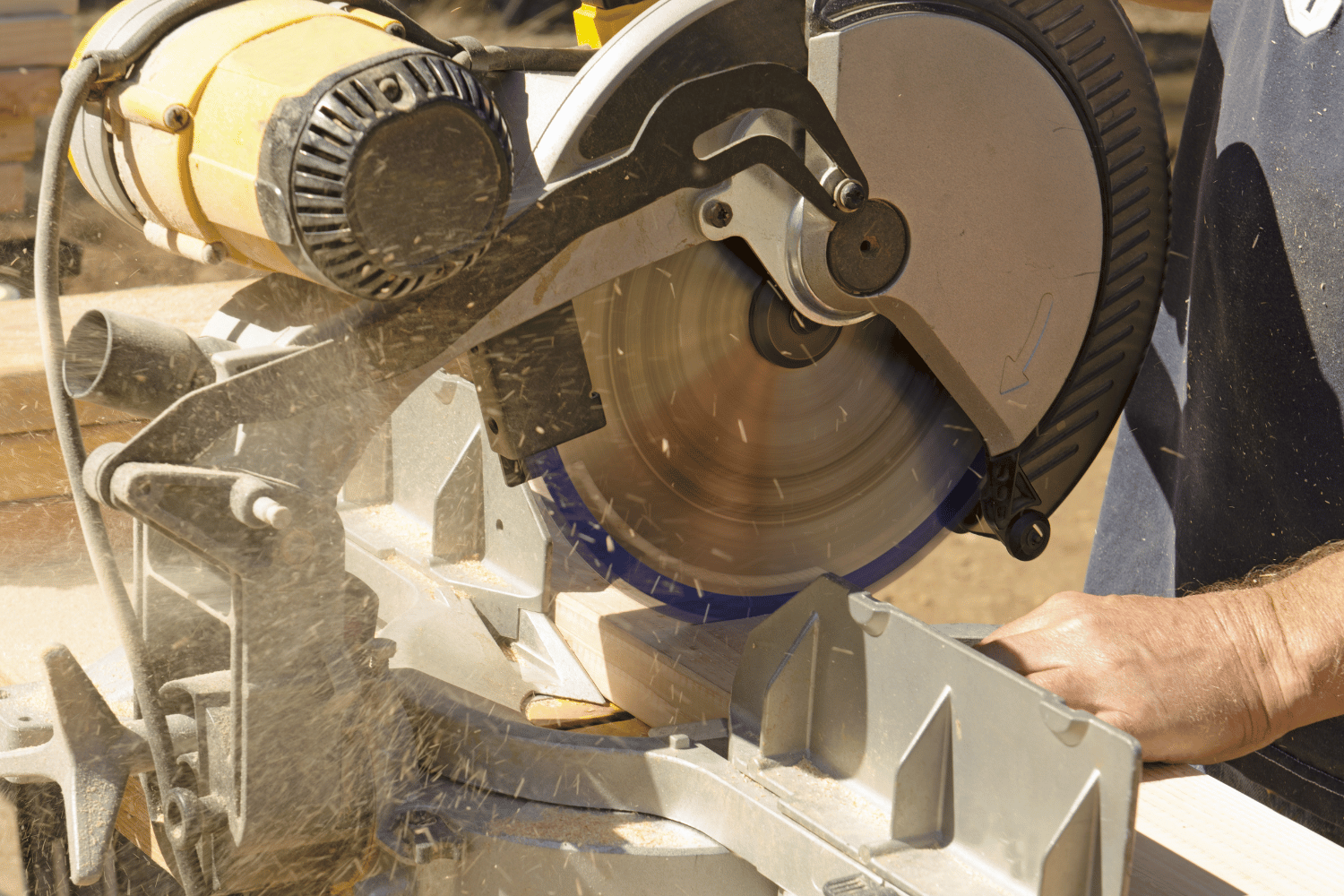

Miter saws are power tools designed for creating precise crosscuts and cutting complex angles. Their pivoting blade makes them ideal for more controlled cuts than a table saw. Miter saws come in two varieties: basic and compound. They can be either portable or mounted on a table, offering flexibility in terms of workspace setup.

A 12-inch miter saw is recommended for increased cutting capacity, accommodating cuts up to 3-12 inches thick. The saw operates by securing the stock on the table and bringing the blade into contact with the wood to create the cut.

Sliding compound miter saws add the ability to move the blade across the workpiece, further expanding their cutting capabilities.

Key Features

Miter saws are available in basic and compound varieties, each with its own unique features. Basic miter saws are designed for making accurate crosscuts and angular cuts, while compound miter saws can also make bevel cuts. The ability to create compound miter cuts, which involve both angled and beveled cuts, is a significant advantage of compound miter saws over their basic counterparts.

Some additional features of miter saws include extension arms for added support and a stop block for cutting multiple narrow boards to the same length. These features, combined with the tool’s overall accuracy and precision, make miter saws an invaluable asset in any woodworking workshop.

Ideal Uses of a Miter Saw

Miter saws excel in making precise miter cuts, bevel cuts, and compound miter cuts, which are essential for the installation of trim work like baseboards and crown molding. They can execute straight cuts, angled cuts, bevel cuts, and combination cuts, offering versatility in the types of cuts they can accomplish.

Double-beveled miter saws are particularly advantageous for trim work, as they can tilt in either direction, enabling bevel cuts on both the right and left side of the board. This versatility makes miter saws an excellent choice for projects involving multiple angles and bevels, such as picture frames, furniture, and home improvement tasks.

Is a miter saw the one? Check out our picks of the best miter saws out there!

Understanding Table Saws

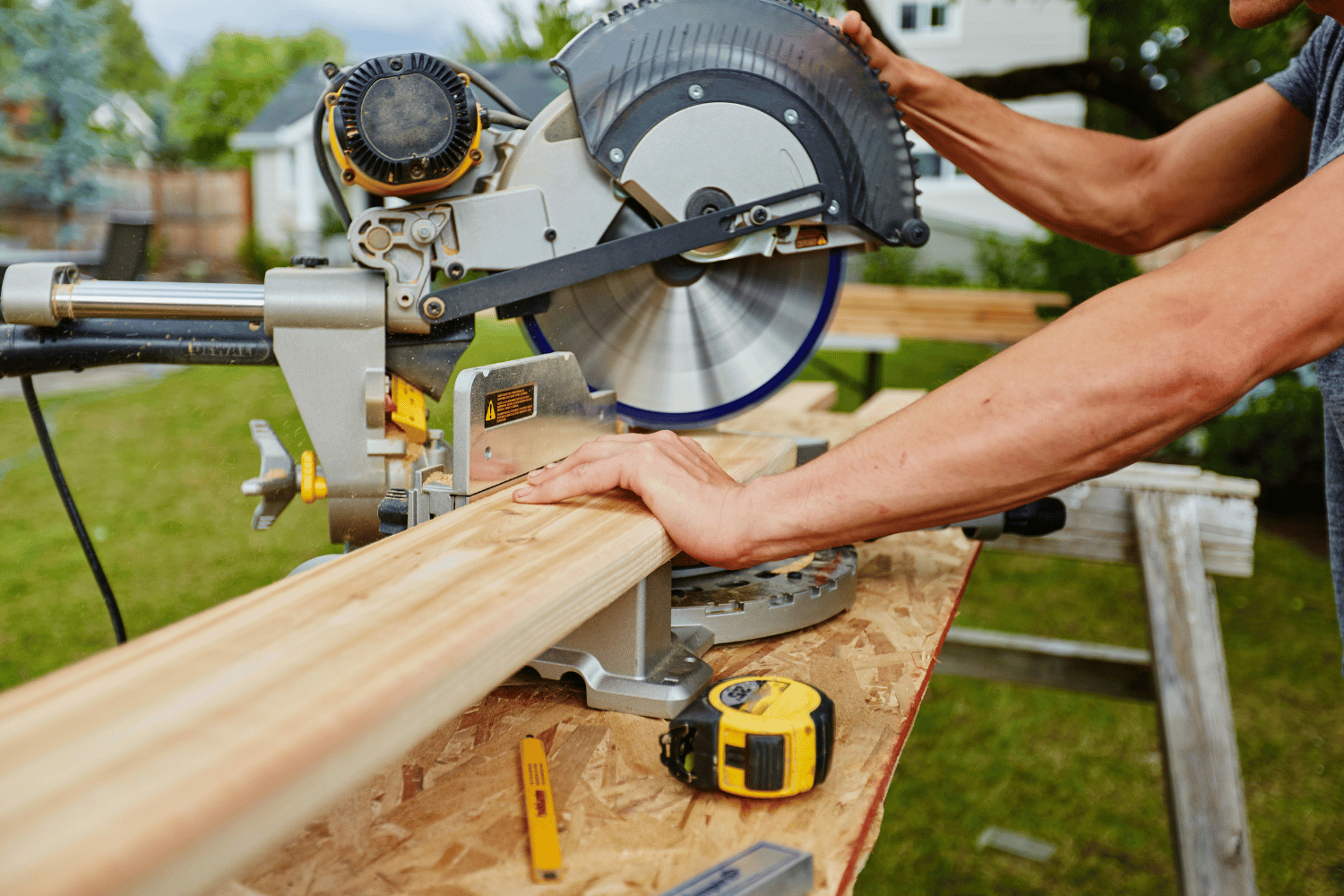

Table saws, like miter saws, are essential power tools in woodworking workshops. They feature a circular blade mounted on a flat table top and are frequently used for making a variety of cuts, particularly rip cuts. Table saws come in three variations, including a mobile option for job-site woodworkers who do not have their own base.

One of the main benefits of a table saw is its ability to accommodate longer and wider materials, making it a versatile tool for handling large workpieces. While you can also crosscut with a table saw using a sled or miter gauge, miter saws are typically more accurate and precise for such cuts.

Key Features

Table saws are available in two distinct variants: portable jobsite saws and stationary cabinet saws. Each of these varieties boasts of different advantages for different types of projects. Portable table saws are mounted on a stand and can be transported to job sites, while cabinet table saws are usually more powerful, precise, and are kept in a workshop.

Key features of table saws include a rip fence for guiding the material during cutting and a miter gauge for making angled cuts. Safety precautions, such as wearing safety glasses, using a dust mask, and employing a push stick to keep hands away from the blade, are essential when operating a table saw or miter saw.

Ideal Uses

Table saws are suitable for a wide range of woodworking tasks due to their versatile cutting capabilities. They can make precise cuts in wood, including crosscuts, rip cuts, and bevel cuts, as well as execute angled cuts like miter cuts and compound cuts.

The expansive work surface of a table saw allows for the handling of large workpieces, such as plywood sheets, making it a valuable tool for producing precise cuts in substantial pieces of wood. This versatility makes table saws an indispensable power tool in any woodworking workshop.

Is the table saw the one you need? Check out our top choices!

Comparing Miter Saw and Table Saw Capabilities

In this section, we will compare the accuracy and precision, versatility, and cutting capacity of miter saws and table saws.

Understanding the distinctions between these two tools will help you make an informed decision on which one is best suited for your woodworking projects.

Accuracy and Precision

When it comes to accuracy and precision, miter saws have the upper hand for intricate and compound cuts. Their design and features allow for greater control and accuracy when making miter cuts, bevel cuts, and other similar cuts.

Table saws are renowned for their accuracy when making rip cuts. These cuts are used to reduce the width of a board or break down sheets of plywood. While table saws are versatile and can perform a variety of tasks, they generally do not offer the same level of precision as miter saws for specific cuts.

Versatility

Miter saws offer a high degree of precision for a limited range of cuts, making them ideal for projects requiring intricate and compound cuts like trim work and crown molding installation. However, their limited cutting range can be a drawback for some woodworking tasks, especially when compared to the more general-purpose nature of table saws.

Table saws, on the other hand, provide a wide range of cutting capabilities and can handle larger workpieces, making them a more versatile option for many woodworking projects. While they may not offer the same level of precision as miter saws for certain cuts, their ability to perform a variety of tasks makes them a valuable addition to any workshop.

Cutting Capacity

In terms of cutting capacity, miter saws can make 6-12″ wide crosscuts, while table saws can accommodate any length. The cutting capacity of a miter saw is determined by the diameter of its blade as well as whether it is a compound or sliding compound miter saw. These two factors must be considered when deciding on a miter saw. A 12-inch miter saw is capable of making cuts up to 3-12 inches in thickness. This powerful tool can easily handle thicker materials.

Table saws, on the other hand, have a more extensive cutting capacity due to their larger work surface and ability to handle longer and wider materials. This makes table saws better suited for tasks requiring extensive cuts or handling large workpieces, such as breaking down plywood sheets.

Portability and Space Requirements

Miter saws are generally more portable and lightweight than table saws, making them easier to transport and set up in different locations. This can be especially advantageous for woodworkers who frequently move between job sites or have limited workshop space.

Table saws, on the other hand, are typically bulkier and heavier, which can make them more challenging to move and require more space in a workshop. Job-site table saws, which do not have their own bases and must be set atop a stable workbench or table, can be a more portable option for those who need the versatility of a table saw but have limited space or frequently move between job sites.

Safety Considerations

When using miter saws and table saws, it’s essential to be aware of the safety risks associated with each tool. Table saws are more prone to causing injuries due to kickback, a sudden and forceful backward movement of the workpiece. Most accidents caused by miter saws, on the other hand, occur during hand switching and lowering the blade with the hand holding the wood.

To mitigate these risks, it’s crucial to follow the manufacturer’s safety guidelines and always wear appropriate safety gear, such as eye and ear protection. Additionally, proper hand placement and the use of clamps and push sticks can help prevent injuries when using these powerful woodworking tools.

Budget and Investment

When considering the cost of a miter saw versus a table saw, the difference is typically insignificant. The price of both tools can range significantly depending on the brand, features, and quality.

Ultimately, your decision should be based on the specific needs of your woodworking projects and the capabilities of each tool rather than solely focusing on the cost.

Choosing the Right Tool for Your Projects

So, how do you choose between a miter saw and a table saw for your woodworking projects? It’s essential to evaluate the specific needs of your projects and the capabilities of each tool. A miter saw provides precision and accuracy for a limited range of cuts, making it a versatile and suitable choice for all sorts of projects, from trim work to crown molding installation.

On the other hand, a table saw adds versatility to your setup, allowing you to make a variety of cuts, including rip cuts, crosscuts, and bevel cuts. While it may not offer the same level of precision as a miter saw for certain cuts, its ability to handle larger workpieces and perform a range of tasks makes it a valuable addition to any workshop.

Summary

In conclusion, both miter saws and table saws have their unique advantages and disadvantages, making them indispensable tools in any woodworking workshop. Miter saws offer greater accuracy and precision for intricate and compound cuts, while table saws provide versatility and the ability to handle larger workpieces.

When choosing between these two tools, it’s essential to consider the specific needs of your woodworking projects and the capabilities of each tool. By understanding the differences in accuracy, precision, versatility, and cutting capacity, you can make an informed decision on which tool is best suited for your projects.

So go forth and create! With the right tool in hand, your woodworking projects will reach new heights of precision, versatility, and efficiency. Remember, the key to success lies in selecting the appropriate tool for each task and always keeping safety and best practices in mind.

Table Saw 101 – Find the Best Table Saw for Beginners