Choosing the Right Drill Bit: Your DIY Success Solved

Are you tired of struggling with inaccurate and inefficient drilling operations? You’re in the right place!

Choosing the right drill bit is the key to achieving precise and speedy results. With a wide range of options available, it’s crucial to match the drill bit to your specific needs.

Whether you’re working with wood, metal, or concrete, understanding the different types of drill bits and their purposes is essential.

In this article, we’ll guide you through the basics of drill bits and provide pro tips for selecting the perfect one.

Get ready to elevate your drilling game and belong to the league of experts!

Key Takeaways

- The drill bit anatomy consists of the shank, body, and cutting edge, and it is important to consider the material and desired hole size when selecting a drill bit.

- Different drill bit materials, such as high-speed steel, cobalt, carbide, and diamond, are used for specific applications and hardness levels of materials being drilled.

- It is crucial to choose the appropriate drill bit type for the drilling task at hand, including twist bits for general drilling, masonry bits for concrete and stone, and spade bits for larger holes.

- Selecting the right drill bit size is essential for accurate drilling, and investing in a bit set can provide versatility and convenience for various projects.

Understanding Drill Bit Basics

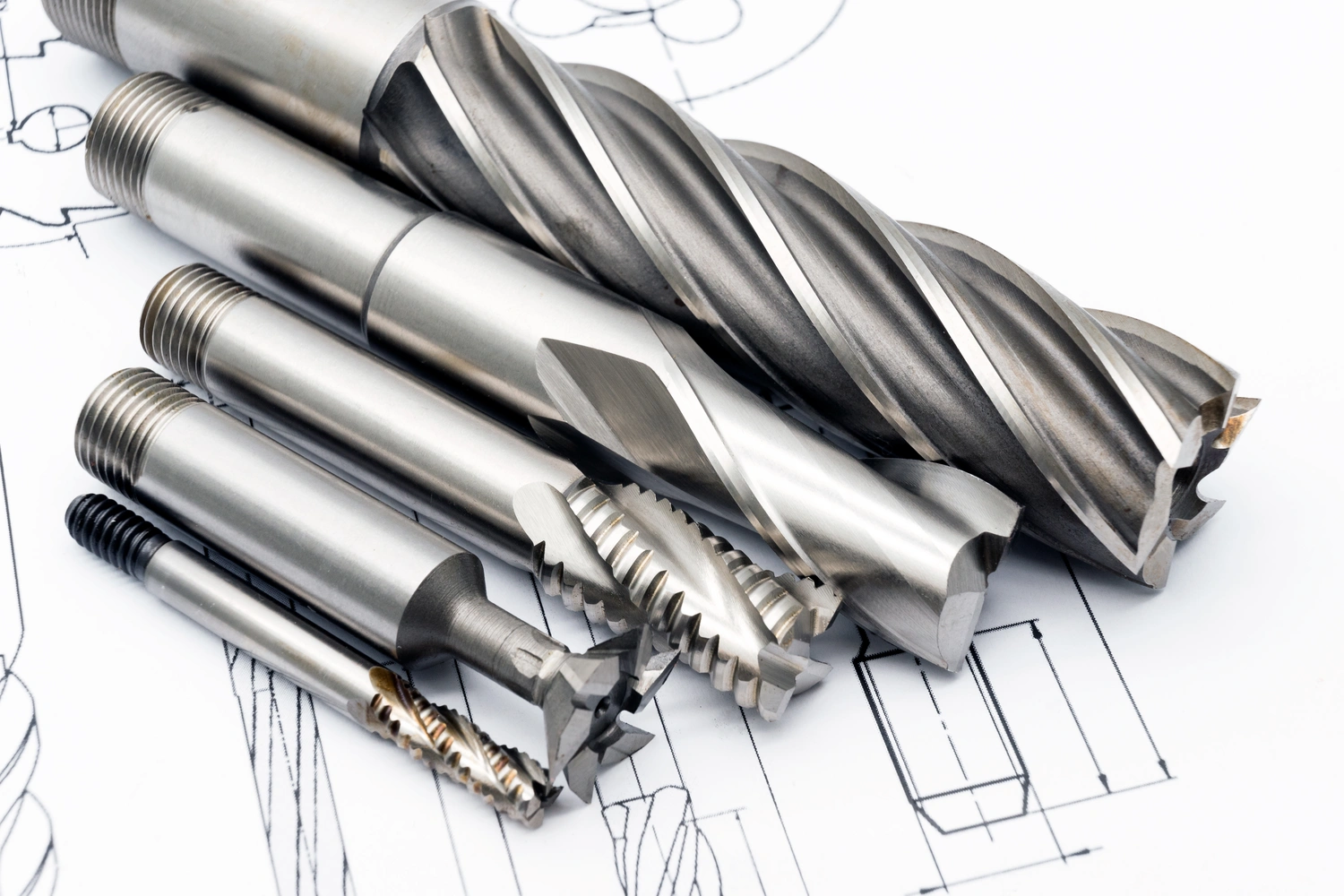

When it comes to choosing the right drill bit, it’s important to understand the anatomy and types available.

The anatomy of a drill bit consists of several key components, including the shank, flute, and point.

Different types of drill bits, such as twist bits, masonry bits, and spade bits, are designed for specific materials and drilling applications.

Drill Bit Anatomy

When it comes to choosing the right drill bit, it’s important to understand the key components and the types of materials they’re made of.

The key components of a drill bit include the shank, body, and cutting edge. The shank is the part that fits into the drill, while the body houses the cutting edge.

Speaking of which, drill bits can be made from a variety of materials such as high-speed steel, cobalt, carbide, and diamond.

The Key Components

The key components of choosing the right drill bit include considering the material being drilled and the desired hole size. To make an informed decision, keep the following factors in mind:

- Drill Bit Material: Different materials require specific drill bits. For example, masonry drills are designed for concrete and stone, while wood drills are suitable for wooden surfaces.

- Drill Bit Size: The size of the hole needed determines the drill bit size. Ensure you select a bit that matches your desired hole diameter.

- Twist Drill Bit: This versatile type of bit is commonly used for general drilling tasks in various materials.

- Bit Set: Investing in a bit set provides you with a range of options for different drilling needs, offering versatility and convenience.

Types of Drill Bit Materials

To select the appropriate drill bit material, you should consider the type of material you are drilling into and its hardness.

For general-purpose drilling in wood and light metals, high-speed steel twist drills are suitable.

Masonry drill bits, on the other hand, are designed for drilling into concrete, brick, and stone.

For drilling through tough materials like stainless steel and cast iron, cobalt drill bits are recommended.

For harder materials such as hardened steel and cemented carbide, carbide drill bits are the best choice.

Remember to choose the appropriate bit size for your project to ensure accurate drilling.

Drill Bit Types

When it comes to drill bits, it’s important to understand the common types and their uses. From twist bits for general drilling to spade bits for larger holes, each type serves a specific purpose in various applications.

Additionally, there are specialty drill bits designed for unique projects, such as masonry bits for drilling into concrete or glass and tile bits for working with delicate materials.

Understanding the different types of drill bits and their uses will ensure you have the right tool for the job, whether it’s a common task or a specialized project.

Common Types and Their Uses

There are several common types of drill bits and their uses vary depending on the material being drilled.

Here are four types of drill bits and their specific uses:

- Twist Bit: This is the most common type of drill bit, suitable for drilling into wood, plastic, and thin metal.

- Step Drill Bit: Ideal for drilling holes of various sizes in sheet metal and plastic.

- Countersink Drill Bit: Used to create a conical hole to accommodate screws and bolts, ensuring a flush finish.

- Spade Drill Bit: Designed for drilling large holes in wood and plastic, with a flat blade shape for faster cutting.

Specialty Drill Bits for Unique Projects

Specialty drill bits offer specific advantages over standard drill bits and are designed for unique projects. These specialized tools include the self-feed drill bit, installer drill, forstner drill bit, tile drill, brad-point drill, and carbide-tipped drill.

The self-feed drill bit is ideal for fast and efficient drilling in wood. The installer drill is designed for drilling holes in drywall and other materials. The forstner drill bit creates clean, precise holes in wood. The tile drill is specifically designed for drilling through ceramic tiles. The brad-point drill is perfect for accurate drilling in wood, while the carbide-tipped drill bit is suitable for drilling through various tough materials.

These specialty drill bits provide the necessary precision and performance for specific projects, ensuring successful results and cost-effective solutions.

Matching Drill Bits to Materials

When it comes to woodworking, having the right drill bit can make all the difference in creating wonders with wood. From standard twist bits to brad point bits, there are a variety of options to choose from depending on the specific woodworking task at hand.

Similarly, for metalwork, using the appropriate drill bit can work its own kind of magic. Whether it’s a high-speed steel bit for general metal drilling or a cobalt bit for harder metals like stainless steel, the right drill bit can make the job easier and more efficient.

And let’s not forget about masonry, where the right drill bit can help you achieve marvels in concrete, brick, or stone. Whether it’s a carbide-tipped bit for drilling into concrete or a diamond core bit for creating precise holes in granite, having the right drill bit for the job is essential for achieving optimal results in any material.

Woodworking Wonders

When it comes to drilling in wood, it is crucial to choose the right drill bit for the job. The best drill bits for wood are those that are specifically designed for wood drilling, such as brad point bits or spade bits. These types of drill bits have sharp, pointed tips that help to create clean and precise holes in wood.

To achieve a smooth and clean drilling experience in wood, it is important to use the correct drilling techniques. This includes applying consistent pressure, using a steady hand, and ensuring that the drill bit is properly aligned with the desired drilling location.

Additionally, using a drill with variable speed settings can also contribute to achieving a smoother and cleaner drilling outcome in wood.

Best Drill Bits for Wood

To get the best results when drilling into wood, you should consider using a twist drill bit. These types of drill bits are designed specifically for wood and are highly efficient in creating clean and precise holes.

When choosing a drill bit for your project, it’s important to consider the diameter of the hole you need, as well as the type of wood you are working with. Additionally, different types of drill bits are used for specific applications, such as spade bits for larger holes and brad point bits for more accurate drilling.

Tips for Smooth and Clean Drilling in Wood

Using a twist drill bit designed for wood can help achieve smooth and clean drilling results.

When drilling holes in wood, it’s crucial to choose the right drill bit size. A bit that’s too small may cause the wood to splinter, while a bit that’s too large can lead to rough and uneven holes.

To ensure smooth drilling, select a bit that matches the size of the hole you need to create. This will help you achieve clean and professional-looking results.

Metal Magic

When it comes to drilling through metal, selecting the right drill bit is crucial to achieve precision and accuracy. The type of metal being drilled, the desired hole size, and the drilling technique all play a role in determining the appropriate drill bit.

Techniques for precision drilling in metal include starting with a pilot hole, using cutting fluid to reduce heat and friction, and applying consistent pressure to maintain control throughout the drilling process.

Selecting Drill Bits for Metal

You’ll want to consider the hardness of the metal when selecting a drill bit. Different drill bit types are designed for drilling into specific materials.

For drilling into metal, HSS drill bits or steel bits are commonly used. The size of the drill bit will depend on the desired hole diameter. HSS drill bits are made from high-speed steel, while steel bits are made from hardened steel.

It’s crucial to choose the right drill bit to ensure efficient and accurate drilling into metal.

Techniques for Precision Drilling in Metal

For precision drilling in metal, it’s important to hold the drill steady and maintain a consistent speed throughout the drilling process.

To achieve this, choose the right drill bit for the job. For metal, a twist drill bit with a sharp point and a high-speed steel construction is recommended.

Additionally, employing the correct drilling techniques, such as applying steady pressure and using lubrication, will ensure accurate and clean holes in your metal workpieces.

Masonry Marvels

When it comes to exploring masonry drill bits, it’s essential to understand their functionality and purpose. These specialized drill bits are designed to tackle tough materials like concrete and brick with precision and efficiency.

However, it’s equally important to prioritize safety when drilling into these materials to avoid any accidents or damage.

Exploring Masonry Drill Bits

Exploring masonry drill bits can help you tackle tough materials like brick and concrete. These specialized drill bits are designed to effortlessly create holes in masonry surfaces, allowing you to complete your projects with ease.

Here are four types of masonry drill bits to consider:

- Masonry Drill Bit: These bits, commonly used with hammer drills, feature a carbide tip that can penetrate through brick, stone, and concrete.

- Step Drill Bit: Ideal for enlarging holes, step drill bits have multiple cutting edges that gradually widen the hole.

- Countersink Drill Bit: Used for creating a chamfered opening, countersink drill bits are perfect for woodworking projects.

- Wood Drill Bit: Although not specifically designed for masonry, wood drill bits can still be used on softer masonry materials.

Remember to select the appropriate diameter for your drill bit, as different tasks require different hole sizes. With the right masonry drill bit in your arsenal, you can confidently tackle any project involving tough materials.

Tackling Concrete and Brick Drilling Safely

Tackling concrete and brick drilling safely requires the right drill bit, proper equipment, and precautions.

When choosing a drill bit for concrete and brick, opt for a carbide-tipped bit, as it is designed to withstand the hardness of these materials. Ensure the bit has a sharp cutting edge and is suitable for rotary drilling.

Remember to wear safety goggles, gloves, and a dust mask to protect yourself from flying debris and harmful dust particles.

Always follow the manufacturer’s instructions for safe and efficient drilling.

Factors Affecting Drill Bit Selection

When it comes to selecting the right drill bit for your project, there are several factors to consider.

First, you need to take into account the specifics of your project, such as the type of material you will be drilling into and the desired end result.

Next, it’s important to ensure that the drill bit you choose is compatible with the type of drill you will be using.

Project Specifics

When it comes to choosing the right drill bit for your DIY projects, it’s important to tailor your selection to the specific task at hand. Different materials and drilling applications require different types of drill bits to ensure optimal results.

In this discussion, we will explore various DIY project examples and guide you through the process of selecting the appropriate drill bit for each task. We will provide you with the knowledge and technical insights needed to achieve professional-level results.

Tailoring Your Drill Bit Choice to the Task

To ensure optimal performance, it’s important to match your drill bit choice to the specific task at hand. Here are four factors to consider when tailoring your drill bit choice:

- Material: Different drill bits are designed to work best with specific materials such as wood, metal, or concrete. Choosing the right drill bit for the material you’re drilling into will ensure efficient and effective results.

- Size: The size of the hole you need to drill will determine the diameter of the drill bit you should use. Using the right size will prevent damage to the material and ensure a clean and accurate hole.

- Purpose: Consider the purpose of your drilling task. Are you drilling for a pilot hole, enlarging an existing hole, or creating a countersink? Each purpose requires a specific type of drill bit to achieve the desired result.

- Coating: Some drill bits come with coatings, such as titanium or carbide, that enhance their durability and performance. Choosing a coated drill bit can improve the longevity of the bit and optimize its performance for the task at hand.

Drill Type Compatibility

When it comes to choosing a drill for your projects, there are a few key points to consider.

First, you need to decide between a cordless or corded drill. Cordless drills offer the convenience of mobility, while corded drills provide a constant power source.

Next, you should consider whether you need an impact drill or a standard drill. Impact drills are designed for heavy-duty tasks and offer additional torque, while standard drills are more versatile for everyday drilling needs.

Understanding these differences will help you select the right drill for your specific projects.

Cordless vs. Corded Drills

Although cordless drills offer more portability, corded drills typically provide more power and consistent performance. When choosing a drill, consider the following:

- Common Type of Drill Bit: Ensure that the drill you choose is compatible with the most commonly used drill bits, such as twist bits and masonry bits.

- Drill Bit Set: Look for a drill that comes with a variety of drill bits, including high-speed steel (HSS) bits and carbide-tipped bits, to handle different materials.

- Self-Feed Drill: If you frequently work with wood, consider a drill that is compatible with self-feed drill bits for efficient and clean drilling.

- Drill Presses: For precision drilling, consider a corded drill that can be used with a drill press, providing stability and accuracy.

Remember to choose a drill that suits your specific needs and projects, whether it’s for home improvement or professional use.

Impact Drills and Standard Drills

Impact drills are known for their high torque and ability to drive screws and fasteners with ease. When it comes to choosing the right drill bit for the job, there are various options available.

Drill bits come in different sizes and materials, each designed for specific tasks. For example, if you need to drill wood, a wood drill bit is the best option.

Remember to always position the bit correctly and use drill bits designed for the type of material you are working with.

Size Matters

When it comes to drill bit size, there are two key considerations: diameter and length.

Choosing the right diameter is crucial for achieving the desired hole size and ensuring proper material removal.

Additionally, the length of the drill bit must be carefully selected to ensure it reaches the desired depth without causing any issues.

Diameter and Length Considerations

One important factor to consider when choosing a drill bit is the diameter and length. These two aspects play a crucial role in determining the effectiveness and efficiency of your drilling operations. Here are four key considerations to keep in mind:

- Diameter: The size of the hole you need determines the diameter of the drill bit. Smaller jobs may require smaller diameters, while larger projects might call for larger bits.

- Length: The length of the drill bit is determined by the thickness of the material being drilled. It’s essential to choose a bit that is long enough to penetrate the material fully without being too long and causing unnecessary friction.

- Material Compatibility: Different drill bits are designed for specific materials. Consider the material you’ll be drilling into, such as wood, metal, or concrete, and choose a bit that is compatible with that material.

- Shank Type: The shank is the part of the drill bit that fits into the drill’s chuck. It’s important to ensure that the shank type matches your drill’s chuck type to ensure a secure fit and optimal performance.

Avoiding Common Size Pitfalls

To avoid common size pitfalls, it’s crucial to consider the diameter and length of the drill bit when selecting the appropriate one for your drilling needs.

Drill bits come in various sizes, and understanding which size drill bit to use is essential for achieving accurate and efficient results. The right bit will depend on the material you’re drilling into and the specific task at hand.

In general, drill bits are typically used to drill holes in a wide range of materials, such as wood, metal, and concrete. By choosing the right bit, you can ensure that your drilling experience is smooth and successful.

Pro Tips for Choosing Drill Bits

When it comes to maintaining drill bits, safety should always be your top priority. Proper maintenance not only extends the lifespan of your drill bits but also ensures safe and efficient drilling operations.

In this discussion, we will explore important tips and techniques for maintaining drill bits, including inspection, cleaning, and storage practices. By following these guidelines, you can maximize the performance of your drill bits while minimizing the risk of accidents or damage.

Maintaining Drill Bits

To ensure the longevity of your drill bits, it is crucial to employ proper maintenance techniques.

Extending the lifespan of your drill bits involves regular cleaning and sharpening. Cleaning removes debris and residue that can hinder their performance, while sharpening ensures that the cutting edges remain sharp and effective.

Extending the Lifespan

One way to extend the lifespan of drill bits is by using lubrication during the drilling process. Lubrication helps reduce friction and heat buildup, which can cause the bit to wear out quickly.

Here are four tips to help you extend the lifespan of your auger drill bit:

- Choose the right drill bit for the job: Different materials require different types of bits, so make sure you select the appropriate one for the material you’re drilling into.

- Use a slow and steady drilling speed: High speeds can cause excessive heat and wear on the bit.

- Avoid excessive pressure: Let the drill bit do the work and avoid applying too much force, as this can also lead to premature wear.

- Regularly clean and inspect the bit: Remove any debris and check for any signs of damage or wear.

Cleaning and Sharpening Techniques

Now that you know how to extend the lifespan of your drill bit, let’s delve into the important topic of cleaning and sharpening techniques.

Proper maintenance is crucial for ensuring optimal performance and longevity of your drill bit. Cleaning your drill bit regularly removes debris and prevents buildup, while sharpening techniques help maintain a sharp cutting edge.

Safety First

When it comes to using drill bits, safety should always be your top priority.

Following drill bit safety guidelines is essential to prevent accidents and injuries.

Make sure to wear the appropriate protective gear, such as safety glasses and gloves, and take necessary precautions to ensure a safe drilling experience.

Safety Guidelines

It’s important to follow these safety guidelines to prevent accidents and injuries. Here are four important tips to keep in mind:

- When drilling a hole, always make sure to use the correct size bit for the job. Drill bits are designed to handle specific materials and sizes, so using the right one will ensure better results and reduce the risk of accidents.

- If you encounter resistance while drilling, it’s crucial not to force the bit. Instead, you need to pull the bit out slightly and clear any debris from the hole. This will prevent the bit from getting stuck and potentially causing injury.

- Be aware of the small hole in the bit, known as the flute. This is where the chips and debris accumulate during drilling. Regularly check and clean the flute to maintain optimal drilling performance and prevent overheating or binding of the bit

- Lastly, always adhere to drill bit safety guidelines provided by the manufacturer. These guidelines cover important details, such as recommended drilling speeds, proper use of safety equipment, and maintenance tips. Following these guidelines will help ensure a safe and successful drilling experience.

Protective Gear and Precautions

Always remember to wear the appropriate protective gear and take necessary precautions when using a drill bit. To ensure your safety and prevent any accidents, it’s essential to wear safety goggles to protect your eyes from flying debris.

Additionally, using gloves will provide added protection to your hands.

When selecting the right bit for your next DIY project, consider the material you’ll be drilling through. For drilling through wood, a standard twist bit or a spade bit can be used.

Frequently Asked Questions

What Is the Difference Between a Twist Drill Bit and a Spade Drill Bit, and When Should I Use Each One?

A twist drill bit is used for drilling holes in various materials, while a spade drill bit is designed for drilling larger holes in wood or soft materials. Choose the right bit based on your specific drilling needs.

How Do I Determine the Appropriate Drill Bit Size for the Hole I Want to Create?

To determine the appropriate drill bit size for the hole you want to create, measure the diameter of the desired hole and select a drill bit with a matching size. Consider the material and purpose of the hole for optimal results.

Are There Any Specific Safety Precautions I Should Take When Using Certain Types of Drill Bits?

When using certain types of drill bits, it is crucial to take specific safety precautions. Always wear appropriate protective gear, secure your workpiece properly, and be mindful of the drill’s speed and torque.

Can I Use a Drill Bit for Materials Other Than What It Is Specifically Designed For?

Yes, you can use a drill bit for materials other than what it’s designed for. However, it’s important to consider the hardness and composition of the material to ensure optimal performance and avoid damage to the bit or workpiece.

How Often Should I Sharpen or Replace Drill Bits, and What Signs Should I Look for to Indicate They Need Maintenance?

To ensure optimal performance and safety, it is recommended to sharpen or replace drill bits when signs of wear, such as dullness or reduced cutting ability, are observed. Regular maintenance is essential for maintaining efficiency and prolonging the lifespan of your drill bits.