Cutting Edge Insights: A Guide to Miter Saw Blade Types

Miter saws are popular woodworking tools that allow for precise angled cuts. An important part of the miter saw is the blade you use. Choosing the right blade for your miter saw is crucial for getting clean, accurate cuts in your material. In this article, we’ll look at the different types of miter saw blades and their uses.

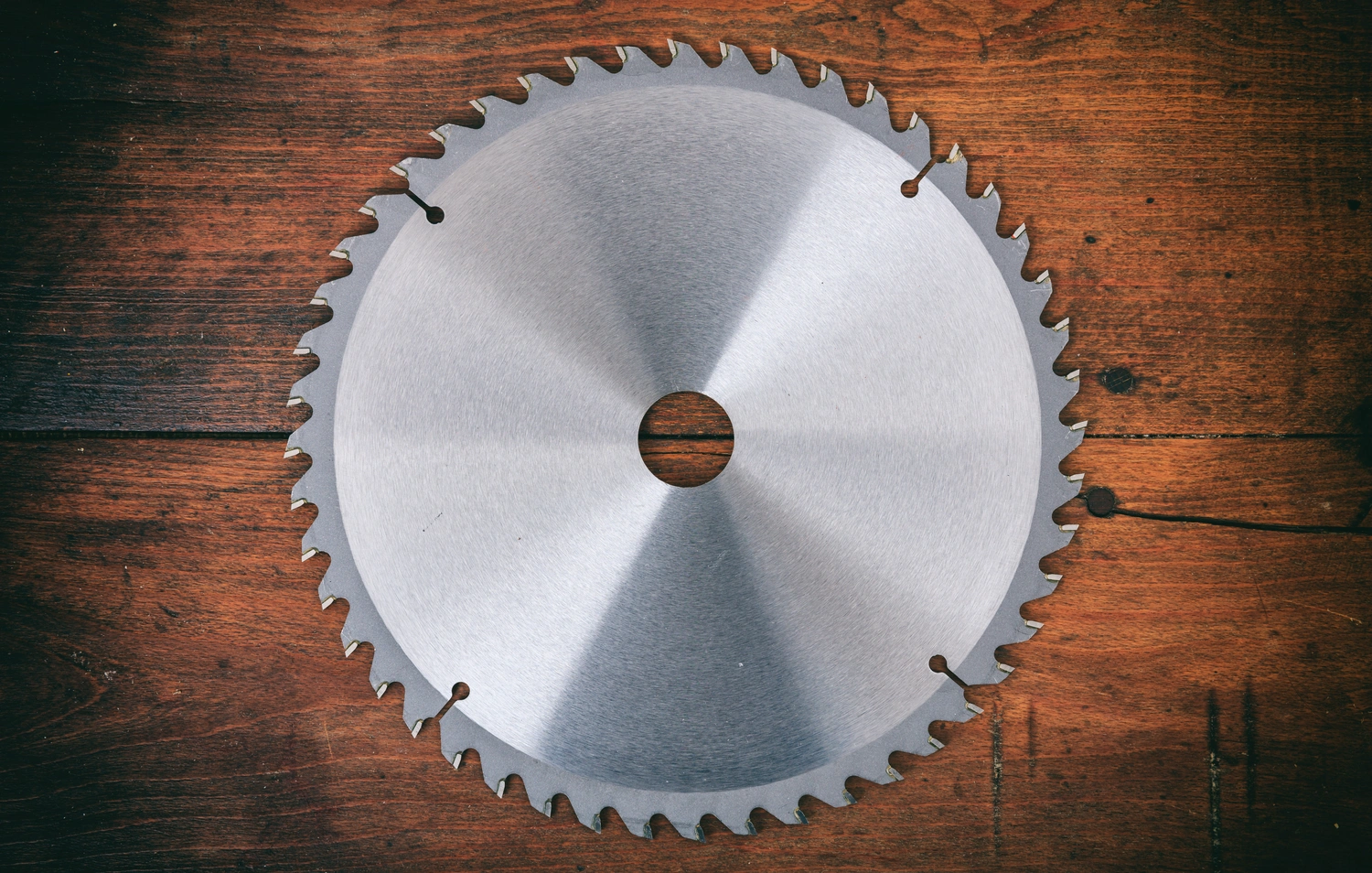

Anatomy of a Miter Saw Blade

Miter saw blades are precision cutting tools carefully engineered to provide smooth, splinter-free cuts. Here are the key components that make up a quality blade:

- Teeth – The teeth do the actual cutting work. Carbide teeth stay sharper longer. Teeth quantity, shape, bevel, and gullet size are designed for crosscutting or ripping.

- Body – The thin metal disc that holds the teeth. A thinner kerf (thickness) wastes less wood. Stiffness and vibration control are important.

- Arbor Hole – The hole in the middle of the blade that fits over the saw’s arbor. Arbors are typically 5/8″ or 1″ in diameter. Match the arbor size.

- Kerf – The width of the cut made by the blade, determined by body thickness. Thinner kerf requires less horsepower.

- Rake – The angle of the front face of each tooth. Positive rake is more aggressive for softwoods, negative rake cleaner in hardwoods.

- Gullet – The valley between teeth that carries away sawdust. Deeper gullets prevent clogging in dense woods.

- Bevel – The angle of the front cutting edge. Bevel allows sharp edge to chisel into material.

- Expansion Slots – Small cuts in the body to absorb heat and avoid warping the blade.

Together, these elements maximize cutting efficiency, accuracy, and blade life. Quality blades precisely balance these factors for the intended purpose whether it be ripping, crosscutting, or fine finish cuts.

Types of Miter Saw Blades

Standard Miter Saw Blades

The most common type of miter saw blade is the standard general purpose blade. These blades are typically 10-12 inches in diameter with 24-80 teeth. More teeth provide a finer cut. Standard blades are made from either high-speed steel or carbide. Carbide blades remain sharper for longer than high-speed steel.

Standard blades are good for basic cross-cutting and mitering in wood. They can handle both softwoods and hardwoods of various thicknesses. While not specialized, a quality standard blade should provide smooth, splinter-free cuts for most DIYers and hobbyists.

Fine Cut Blades

For delicate, detailed work a fine cut blade is ideal. These specialized blades are smaller, usually 10 inch diameter, and have 80 or more very fine teeth. The many small teeth make an ultra smooth cut, which is perfect for precisely cutting molding and trim without tearing or splintering the material.

However, fine cut blades are only designed for thin wood and laminates or veneers. They lack the gullets and rigidity for cutting thicker hardwood stock. Fine cut blades are a must-have for intricate woodworking and furniture making.

Crosscut Blades

Crosscut blades are designed specifically for mitering and cutting across the grain of wood. They prevent splintering and tear-out that can occur when cutting across wood fibers. Crosscut blades have deep gullets between each tooth to efficiently channel sawdust away from the cut as you crosscut.

The sharp beveled teeth slice cleanly rather than tearing ragged edges. Crosscut blades are ideal for cutting framing lumber, plywood, and any situation where you will see the end grain of the wood.

Ripping Blades

In contrast to crosscut blades, ripping blades are designed for cutting with the grain to rip boards to width. Ripping blades have 15-30 large, flat teeth with wide spaces between. This allows for fast ripping cuts but leaves a rough edge not suitable for finish work.

The large gullets clear sawdust rapidly when ripping through thick hardwood stock. Don’t use a ripping blade for crosscuts or mitering as it will splinter the wood. Combine it with a crosscut blade to handle both tasks.

Combination Blades

For those seeking a decent all-around blade, a combination blade is a good compromise. Combination miter saw blades aim to provide suitable performance for both crosscutting and ripping. They have 40-50 teeth to make fairly smooth crosscuts while still allowing decent ripping ability.

While a combination blade won’t excel at specialized cuts, it can handle most amateur needs. Many miter saws come stock with a combination blade suitable for basic functions. For professional work, dedicated crosscut and ripping blades are recommended.

Blades for Cutting Metal

While miter saws are most commonly used for cutting wood, the right blade allows you to cut metal materials as well. Here are some tips on selecting a miter saw blade for metal cutting:

- Use a blade specifically designed for cutting non-ferrous metals like aluminum, copper, brass etc. Do not try cutting steel with a miter saw.

- Carbide-tipped teeth optimized for metal usually have a negative rake angle to prevent teeth from digging in too aggressively.

- For clean cuts in metal, choose a blade with at least 60 teeth. Fine cut blades with 80+ teeth provide the smoothest edge.

- Thinner kerf blades put less strain on the saw and require less horsepower when cutting metal.

- Make sure the blade turning speed does not exceed the max rpm rating for that blade. Going too fast can be dangerous.

- Lubricating blades with cutting wax or oil helps keep the blade cool and avoids buildup of metal material in the teeth.

- Cut slowly and evenly when cutting metal to avoid overheating the blade tips. Let the teeth shave away the metal.

- Expect faster wear from abrasive metal dust so inspect blades frequently for damage or dull teeth.

With a quality carbide-tipped blade designed for non-ferrous metals, you can achieve clean accurate cuts in metals like aluminum. Just remember to follow safety precautions and reduce your feed rate compared to cutting wood. The proper blade makes cutting soft metals on a miter saw possible.

Factors to Consider When Choosing a Blade for your Miter Saw

When selecting a new blade, there are several factors to take into account to get the right blade for your needs and saw.

Tooth Count

The tooth count of the blade determines the size of the teeth and gullets, which controls the smoothness of the cut and cutting speed. Lower tooth counts of 24-40 are faster for ripping but leave a rougher edge. For smooth crosscutting, look for 60-80 teeth. Fine finish blades have 80+ teeth.

Blade Material

Carbide-tipped blades last up to 20X longer than standard high-speed steel. Carbide remains sharper over more cuts. Carbide is recommended for professional shops while home DIYers can opt for quality high-speed steel to balance cost and longevity.

Blade Coating

Some blades have Teflon or other coatings to reduce friction and keep the blade cooler. This protects the teeth and increases the blade life. Coated blades are easier to clean as resin and sap don’t stick as readily.

Saw Manufacturer’s Recommendations

Consult your saw’s manual for the ideal blade diameters, kerf size, arbor size and max speed for your model. Matching the blade specs to your specific saw will ensure safe operation and optimal cutting performance.

Taking the time to evaluate your needs and match the right blade specifications to your saw’s requirements will result in clean, accurate cuts, extended blade sharpness, and the best return on your blade investment.

Tips for Selecting the Right Type of Blade

Choosing the ideal blade for your miter saw is key to achieving the best cuts for your project. Here are some useful tips for selecting the right blade type:

Know Your Project Requirements

Consider what types of cuts your project requires. Will you mainly be doing finish carpentry requiring clean crosscuts? Or rough carpentry with frequent ripping? Specialty blades excel at specific tasks. Buy blades suited for your actual needs.

Consider the Material

The work material determines the best blade choice. Crosscut blades prevent tear-out in natural wood grains. But laminates and man-made composites require a fine finish blade to avoid chipping. Cutting metal or acrylic needs specialty blades. Select blades designed for your workpiece.

Additionally, thin materials call for a thin kerf blade with minimal body thickness to avoid binding. Hard woods need large gullets and teeth to withstand wear. Choosing a blade matched to your material results in superior cutting.

In summary, let your project cuts and work materials guide you in selecting specialty or all-purpose miter saw blades. Investing in the right blade improves cutting accuracy, speed, safety, and prolongs your blade’s sharpness. Take time to evaluate your needs so your blades can deliver optimal performance.

Final Thoughts

Choosing the best miter saw blade for your needs is essential for optimizing cutting performance.

Carefully evaluate your materials and typical cuts to select specialty or all-purpose blades that match your work. The right tooth design prevents splintering and tear-out while a carbide-tipped blade will maintain a sharp edge even under repeated professional use. Investing in quality blades purpose-built for your projects allows your miter saw to deliver its full potential.

With a blade that complements your miter saw and tasks, you’ll achieve faster, smoother, more accurate cuts safely.

What is the significance of the number of teeth on a miter saw blade?

The number of teeth on a miter saw blade determines the quality and type of cuts it can make. Blades with fewer teeth are suitable for fast, rough cuts, while blades with a higher tooth count are ideal for making clean and precise cuts.

What does the term “alternate top bevel” (ATB) mean?

Alternate top bevel refers to the tooth geometry on a miter saw blade. It features alternating bevels on each tooth, which allows for smoother and cleaner cuts.

What is the purpose of the stamp on a miter saw blade?

The stamp on a miter saw blade indicates important information such as the blade diameter, tooth count, and other specifications. It helps users identify and select the right blade for their needs.

Can I use a circular saw blade on my miter saw?

Yes, you can use a circular saw blade on your miter saw, but it’s important to ensure that the blade is suitable for cutting through the specific material you are working with.

How do I choose the right miter saw blade?

To choose the right miter saw blade, consider factors such as the type of material you will be cutting, the desired quality of the cuts, and the size of your saw’s blade plate.

What are the benefits of using a miter saw blade with a high tooth count?

Miter saw blades with a high tooth count are excellent for making smooth and precise cuts on various materials. They produce less tear out and provide a finer finish.

What is the importance of the diameter of the miter saw blade?

The diameter of the miter saw blade determines the maximum cutting depth it can achieve. It is essential to select a blade with a diameter that matches your specific cutting needs and fits in your saw.

Can miter saw blades be used for cutting ferrous materials?

No, miter saw blades are not suitable for cutting ferrous materials such as iron or steel. For such tasks, it is recommended to use specialized blades.