How Does a Hammer Drill Function? – Uncovering the Magic

When you’re working on a home improvement project and come across a hard piece of concrete that your regular drill just can’t get through, that’s when you need a hammer drill. You might be curious how this tool can drill into tough materials so easily.

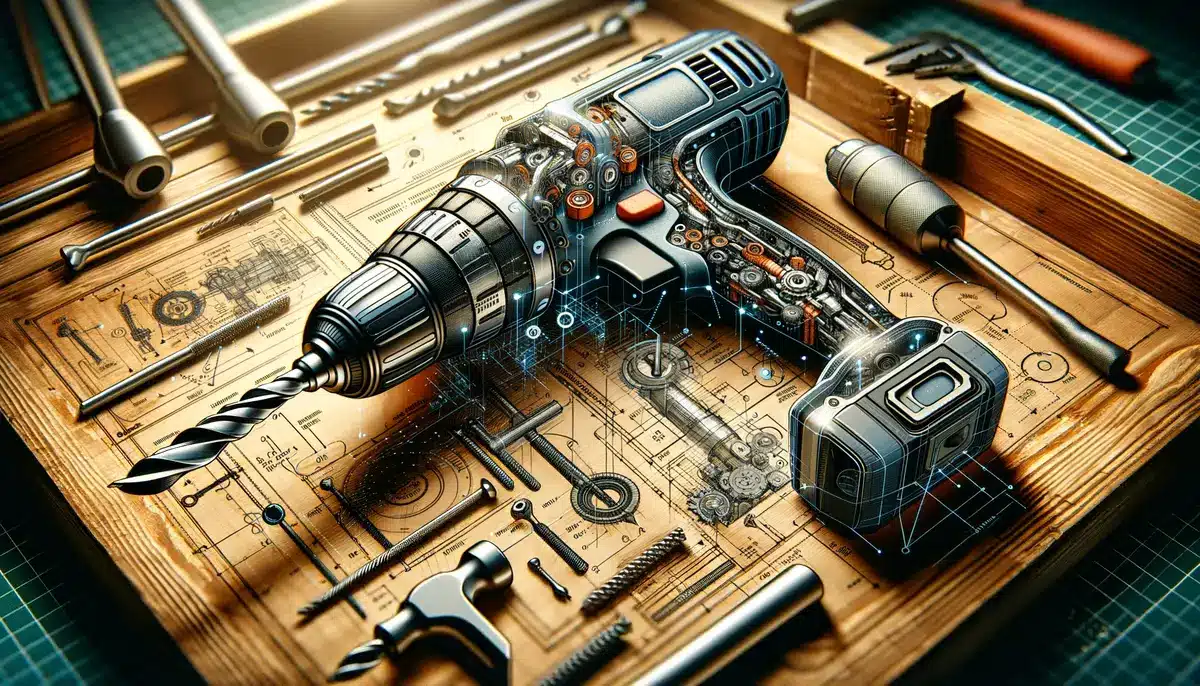

A hammer drill combines the spinning action of a regular drill with the pounding motion of a hammer. This mix lets it break up and drill into hard surfaces that a normal drill can’t touch. So, what’s happening inside this powerful tool to make it both hit and spin at the same time, and how does it do this while still being accurate and safe? Understanding how a hammer drill works helps you see why it’s so effective at breaking through tough barriers when you press its trigger.

For example, when using a hammer drill, you can expect it to not only spin the drill bit but also to hammer it in and out. The gears inside create rotation, while a special mechanism hammers the bit into the concrete. This action is much like a chisel being hit by a hammer, which is why it works so well on hard materials.

The safety comes from the design of the drill that makes sure the force isn’t too much for you to handle. So, when you need to drill into something like concrete or stone, a hammer drill is your go-to tool because it’s designed specifically to tackle these hard-to-drill materials.

Understanding Hammer Drills

To understand how a hammer drill works, it’s important to know that it does two things at once: it spins and hammers. Imagine the front part of the drill, called the chuck, moving quickly in and out while also turning around. This action comes from two toothed wheels inside the drill that work together. When you push on the drill, these wheels make the chuck move in a hammering way along the drill bit’s line.

This helps the drill bit, which usually has a tough tip made for hard materials, to break through things like concrete, brick, or stone. The hammering breaks the material, and the spinning moves the broken bits out of the hole. Knowing how to use a hammer drill means you can do heavy-duty jobs on your own, like putting up shelves on a brick wall or adding fixtures to concrete.

For example, when you’re trying to hang a heavy mirror on a concrete wall, a regular drill mightn’t be enough. But with a hammer drill, you can make holes for the screws easily. If you’re looking to buy one, the Bosch Bulldog Xtreme is a popular choice that many people find reliable and easy to use.

Rotation and Hammering Action

A hammer drill is a powerful tool that makes drilling into tough materials like concrete a lot easier. It works by spinning around, just like a regular drill, thanks to its electric motor. At the same time, it also has a special hammering feature that hits the surface in short, sharp bursts. This is either done by a special part inside the drill that bangs back and forth or by a system that uses air pressure to create the hammering effect. By combining spinning and hammering, the drill can chip away at hard materials, making a hole more quickly than just spinning alone.

These features show how cleverly designed the hammer drill is, giving you the power to drill through tough surfaces with precision and without much effort.

Drill Bit and Power Source

The efficiency of a hammer drill greatly depends on the type of drill bit and the power source it uses. A good drill bit needs to be strong because it has to handle the high pressure and turning force of the drill. Usually, bits made of tough materials like carbide or those with diamond tips are the best choices because they can take the hit and keep working well. The shape of the bit is also important because it helps move the material out of the way and keeps the bit from wearing out too quickly, which also makes the drill cut faster.

On the other hand, how the drill is powered is key to how well it can do its job. Hammer drills that plug into the wall can keep going strong for a long time, which is great for big projects. Battery-powered drills, though, are easy to carry around and use anywhere, but they can’t run as long before needing a recharge. The amount of electricity a drill uses or the strength of its battery affects how much turning power it has. This is what allows the drill to work through different materials that are hard or dense with accuracy and without much trouble.

For example, if you’re planning to drill into concrete, a carbide-tipped bit on a corded hammer drill with a high amperage rating would be a solid choice as it will have the endurance and power needed for such a tough job. On the flip side, for quick tasks like hanging frames on a brick wall, a cordless hammer drill with a decent voltage battery would be more convenient and still get the job done effectively.

Speed, Torque, and Control

Grasping how speed, torque, and control work together is key to getting the best out of your hammer drill for different tasks.

Speed tells you how fast the drill bit spins and is shown in RPM (revolutions per minute).

Torque is the twist force your drill uses to push the bit into hard materials, and we measure it in Newton-meters (Nm).

The control system of your hammer drill lets you change how fast or strong the drill works, depending on what you’re doing. By knowing how to manage the drill’s settings, you can drill more effectively, making sure you don’t shake the drill too much or wear out the material you’re drilling into. This know-how lets you handle various drilling jobs smoothly and confidently.

For instance, if you’re drilling into soft wood, you might choose a high speed and lower torque to get the job done quickly without splitting the wood. On the contrary, for tough concrete, you’d lower the speed and crank up the torque to break through without overheating the bit.

If you’re in the market for a hammer drill, models like the DeWalt DCD996P2 or the Milwaukee 2804-22 are known for their robust control systems, allowing precise adjustments for any drilling challenge.

In short, understanding and adjusting the speed and torque of your hammer drill means you can work smarter, not harder. You’ll drill more efficiently, save time, and extend the life of your tools and materials.

Clutch Disengagement and Safety

When using a hammer drill, it’s important to understand how the clutch works to keep you safe. The clutch is there to stop the drill if it hits something too hard. This prevents the tool from getting damaged and also means you’re less likely to get hurt from the drill suddenly twisting.

To make sure the drill works right and doesn’t stop too soon or too late, you need to check the clutch settings regularly. This helps keep the drill in good shape and makes sure you can work safely.

For example, if you’re drilling into concrete and the drill hits rebar, a well-adjusted clutch will stop the drill from spinning out of control. This can prevent the drill from breaking and also protect your wrist from getting twisted. Remember, using the drill correctly is as important as wearing safety gear like gloves and goggles.

In short, paying attention to how the clutch on your hammer drill is set can save you from trouble. It’s a simple step that makes a big difference in keeping you and your tools safe.

Frequently Asked Questions

Can Hammer Drills Be Used for Purposes Other Than Drilling Into Concrete or Masonry?

Certainly, hammer drills are versatile tools that can be used for drilling into materials like wood or metal, in addition to concrete or masonry. When working with these softer materials, it’s important to turn off the hammer function. This is because the hammering action is designed for breaking through hard, brittle surfaces, and if used on wood or metal, it could ruin both the material and the drill bit.

For example, if you’re putting up shelves and need to drill into wooden studs, your hammer drill can be used just like a regular drill. Make sure to use the appropriate drill bit for wood – this is usually a twist bit or a brad point bit. If you’re drilling into metal, switch to bits made specifically for metal, such as HSS (High-Speed Steel) bits or cobalt bits.

How Does Prolonged Use of a Hammer Drill Affect Its Internal Components and Overall Longevity?

Extended use of a hammer drill can lead to wear and tear on its parts, particularly the gears, and can cause the motor to overheat. This stress on the drill’s components can make it less effective and can eventually lead to it breaking down. To keep the drill working well for as long as possible, it’s important to regularly check and maintain it. For instance, after heavy use, you might need to lubricate the gears or replace worn brushes in the motor. By taking these steps, you can help extend the life of the drill. When choosing a hammer drill, consider models known for durability, such as the Bosch SDS-plus or the DeWalt DCD996B, which are designed to withstand rigorous use. Remember, though, even the best models require care to maintain their performance over time.

Are There Any Alternative Technologies to Hammer Drills That Offer Similar Functionality With Less Noise or Vibration?

Rotary hammers and pneumatic drills are good alternatives to hammer drills. They are quieter and cause less shaking, making them more comfortable to use. This is important because it can reduce fatigue and make it easier to do precise work. For instance, a rotary hammer is particularly effective for drilling into concrete without making too much noise. A pneumatic drill, which uses compressed air, can also be a great choice for heavy-duty tasks with minimal disturbance. Both tools help you get the job done effectively but are easier on the ears and hands. If you’re looking for product recommendations, the Bosch RH328VC Rotary Hammer and the Ingersoll Rand Air Hammer are both known for their performance and reduced vibration. Remember, when using these tools, always wear appropriate safety gear to protect your hearing and hands.

How Does the Weight and Ergonomic Design of a Hammer Drill Impact User Fatigue During Extended Use?

Working with a hammer drill that’s lightweight and designed to fit comfortably in your hand can make a big difference when you’re using it for a long time. This kind of design helps to prevent your wrists and arms from getting tired too quickly. This means you can work longer without feeling worn out. For example, if you’re using a compact hammer drill like the Bosch PSB 500 RE, which is known for its ergonomic design, you’ll likely notice that you can keep working on your project without having to take as many breaks to rest your arms. This is because the drill is made to be easy to hold and use, which is really important when you’re drilling into tough materials like concrete or metal. By choosing a hammer drill that’s easy on your body, you’re also less likely to make mistakes or have an accident because of fatigue. So, not only does it help you work more comfortably, but it also makes your job safer.

Can Hammer Drills Be Effectively Used in Zero-Gravity Environments or Underwater Construction Projects?

Hammer drills can be used in zero-gravity and underwater, but they require special tools to work properly. In zero-gravity, they need attachments that help them push against surfaces without the help of gravity. Underwater, they need waterproof designs to prevent damage and electric shock. These adaptations ensure that they can drill and hammer just as well in space or underwater as they do on Earth. For example, a hammer drill designed for underwater use might be the Nemo Special Ops Drill, which is made to function up to 100 meters deep. In space, NASA often uses tools with special modifications to handle the lack of gravity. Using these tools allows workers to tackle construction tasks in space or underwater efficiently.