Best Wood Lathe to Turn Your Next Masterpiece

If you’re ready to take your woodworking projects up a notch, investing in the right lathe is key.

The best wood lathe has the power to transform everyday pieces of timber into spectacular works of art that will turn heads and last a lifetime.

With so many different kinds of wood lathes on the market, it can be daunting to know which one might be best for you.

Whether you are an experienced DIYer or a professional craftsman, we have put together this guide to help you choose the perfect machine for your needs.

Read on for our comprehensive advice about choosing a great quality wood lathe that will bring out your inner artist!

Looking for something smaller? Check out our picks for the best mini lathes.

How We Choose the Best Wood Lathes

There are a lot of different wood lathes on the market, and it can be hard to figure out which one is the best for you.

Not all wood lathes are created equal. Some are designed for hobbyists, while others are built for professionals.

And then there are the cheap ones that might not last very long.

We’ve taken care of the hard part.

We spent hours poring over reviews and specs and found the best wood lathes for many situations.

Whether you’re a beginner or a pro, we have a lathe that will suit your needs.

Overall Winner – Best Wood Lathe

JET JWL-1840EVS 18″ x 40″ Variable Speed Wood Lathe

Key Features

- 40-1/2-inch working distance between centers

- 18-1/2-inch swing over bed

- 1 Phase, 230V 2HP motor

Why It’s a Great Choice

The JET JWL-1840EVS 18″ x 40″ Variable Speed Wood Lathe is an ideal wood lathe for serious DIYers and professionals who demand only the best.

Boasting an accessible digital readout and electronic variable speed control ranging between 40 to 3,200 RPM, this wood lathe is perfect for high-precision craftsmanship and turning intricate designs with ease.

Plus, its sliding headstock pivots 360 degrees, and 4″ cast iron risers let users adjust the height of the lathe to suit their own needs.

The spindle nose also houses dual headstock spindle bearings that make long-lasting stability a breeze.

Best of all, it features a banjo that uses a non-marring positive locking wedge system to firmly hold your toolpost.

And if you ever need to stop in an emergency, its magnetic-backed remote emergency stop button can be conveniently situated along the lathe bed, giving you peace of mind during operation.

With everything it offers, there’s no doubt why professionals rely on the JET JWL-1840EVS for their most important projects.

Get yours today and experience maximum performance!

Best Wood Lathe for Precision Indexing

Powermatic 3520C 20″ x 35″ Wood Lathe

Key Features

- 35-inch working distance between centers

- 20-inch swing over bed

- 1 Phase, 220V 2 HP motor

Why It’s a Great Choice

When it comes to wood lathes, professionalism is of utmost importance.

And with the Powermatic 3520C 20″ x 35″ Wood Lathe, you can achieve professional results every time.

A heavy-duty workhorse that teams durability and accuracy with power and speed, this outstanding tool will always deliver first-rate outcomes.

With digital indexing readout and a magnetic-backed moveable control box, the Powermatic 3520C delivers precise adjustments, while adjustable riser blocks for the cast iron legs provide a convenient six inches of height adjustment.

The upgrading banjo features a non-marring, pinch-style clamp for easy operation and maximum smoothness in use.

Meanwhile, the self-locating ergonomic spindle lock makes one-handed operation effortless and efficient.

Furthermore, the tailstock has been designed with an Anti-rotation key and Acme threads for smoother functioning and increased durability—able to maintain speeds as low as 15 RPM!

The Powermatic 3520C is backed by their industry-leading 5-year warranty against manufacturing defects—so you can be sure you’re buying a quality machine designed to last.

Choose your next wood lathe from Powermatic: because when demanding professionalism from your results means more than just what’s on the surface!

Best Wood Lathe for Consistent Copies

Grizzly Industrial G0842-14″ x 37″ Wood Lathe with Copy Attachment

Key Features

- 32-inch distance between centers with copy device (37-inches without)

- 14-inch swing over bed

- 1 Phase, 110V 3/4 HP motor

Why It’s a Great Choice

The Grizzly Industrial G0842-14″ x 37″ Wood Lathe with Copy Attachment is a must-have tool for serious hobby furniture makers.

Equipped with a powerful 110V, 3/4 HP motor, and variable speed spindle, this machine offers all the power and precision you need to turn ornate stair spindles, chair, and table legs up to 32″ in length by copying off an existing template or master workpiece.

And once you’re ready to start creating new spindles from scratch, simply drop the copy attachment out of the way and get right to it.

With accuracy, durability, and power all wrapped into one affordable package, the Grizzly Industrial G0842-14″ x 37″ Wood Lathe with Copy Attachment gives do-it-yourselfers and pros alike great value for their money.

Best Mini Wood Lathe

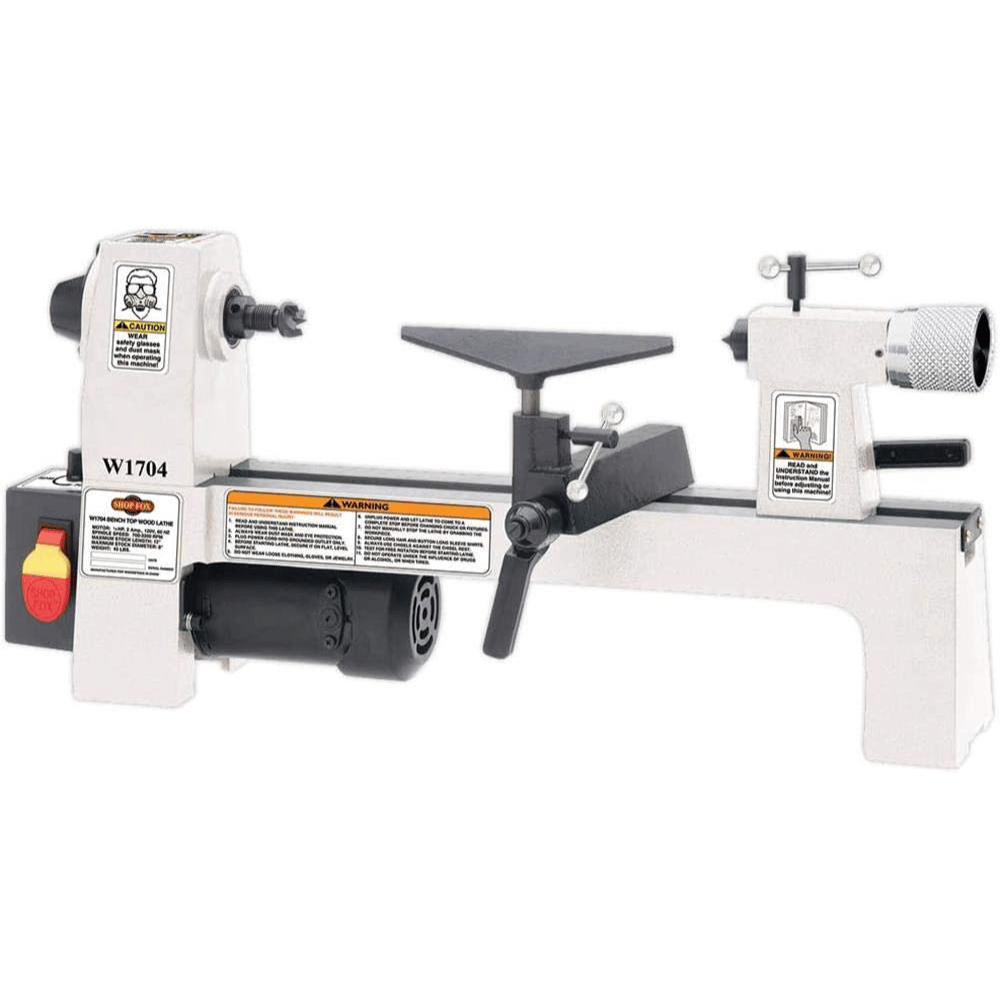

Shop Fox W1704-8″ x 13″ Benchtop Wood Lathe

Key Features

- 13-inch working distance between centers

- 8-inch swing over bed

- 1 Phase, 110V 1/3 HP motor

Why It’s a Great Choice

Introducing the Shop Fox W1704 8″ x 13″ Benchtop Mini Wood Lathe!

Precision and power meet convenience in this sleek benchtop wood lathe.

Durably made with cast iron construction, it features a 1/3 horsepower variable-speed motor, capable of providing spindle speeds between 700 and 3,200 revolutions per minute (RPM).

This machine lets you take on any challenging project with confidence; whether you’re a professional or DIY enthusiast.

Safety is also paramount; it comes equipped with a paddle switch for effortless one-hand operation without compromising power or performance.

The lathe comes with a 5-3/4″ faceplate that can be easily attached to the headstock spindle, enabling you to carry out any non-spindle turning operations.

Enjoy smooth and controlled rotations every time; tackle everything from delicate model development to creating intricate designs with complete control.

Get ready to make sure your next project is done right—the Shop Fox W1704 8″ x 13″ Benchtop Mini Wood Lathe has got you covered!

Best Benchtop Variable Speed Wood Lathe

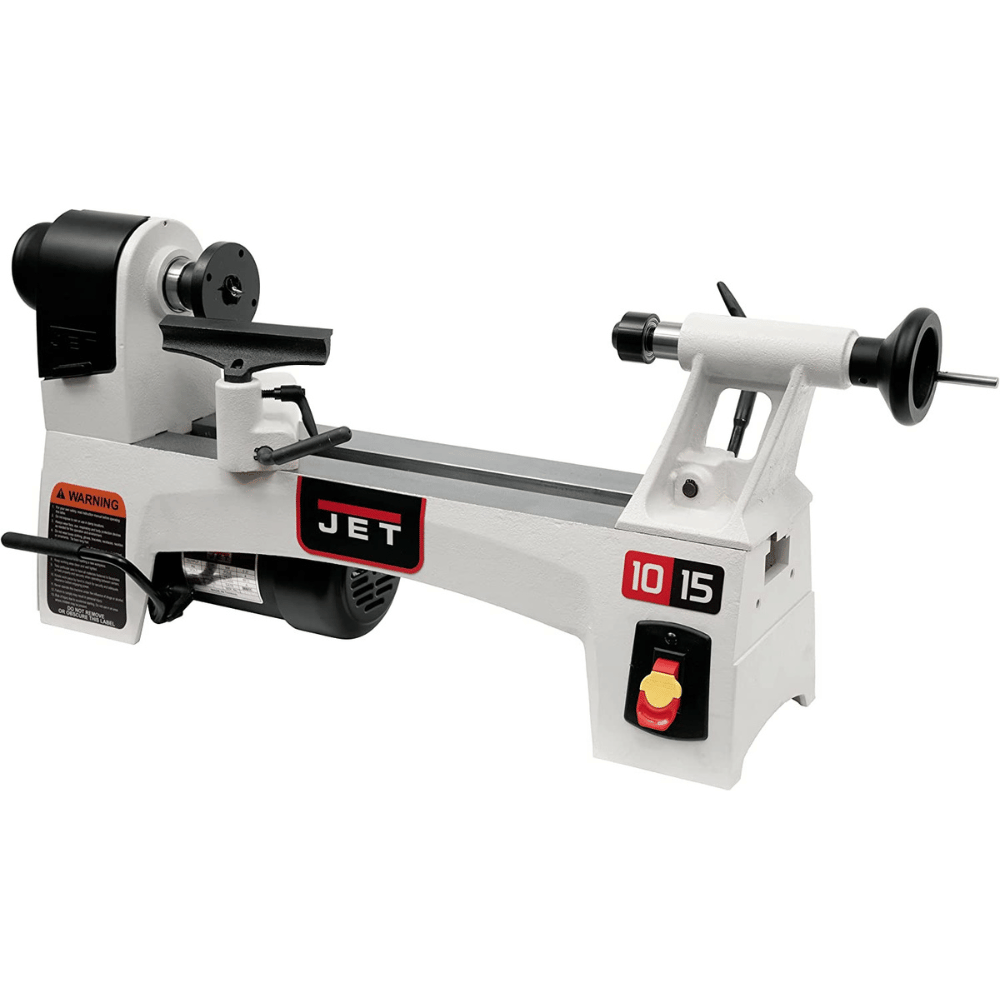

JET JWL-1015, 10″ x 15″ Variable Speed Wood Lathe

Key Features

- 15-1/2-inch distance between centers

- 10-inch swing over bed

- 1 Phase, 115V 1/2 HP motor

Why It’s a Great Choice

The JET JWL-1015 10″ x 15″ Variable Speed Wood Lathe has something to offer both novice and experienced woodturners.

Its enhanced tensioning system allows you to make precise adjustments with improved stability and control.

With six spindle speeds ranging from 500 to 3975 RPM, you can select the perfect speed for any project.

Its 24-position indexing feature adds an extra layer of accuracy so your projects always turn out just the way you want them to.

Plus, its increased rigidity for a mini lathe gives users more stability and support during work, and its improved gripping tailstock features a live center for precision and accuracy.

This lathe is designed with both beginners in mind as well as professionals seeking a full-featured mini-lathe for their shop.

If you’re looking for precision, performance, and affordability in one package, look no further than the JET JWL-1015 10″ x 15″ Variable Speed Wood Lathe!

Buyer’s Guide to the Best Wood Lathes

When looking for a wood lathe, many questions come to mind.

What size should I get?

What is the difference between a benchtop and a floor model?

What are the different types of wood lathes?

The best way to find answers to these questions (and more) is by reading our comprehensive Wood Lathe FAQ.

This guide covers all the basics of wood-turning, from selecting the right tool for your project to understanding the different parts of a lathe.

What is a wood lathe?

A wood lathe is one of the most essential pieces of equipment in woodworking and carpentry. It is a machine used to create objects such as bowls, platters, spindles, furniture parts, and other items by spinning a piece of wood on its axis at one end while various tools are used to shape and cut it at the other.

The main components of a wood lathe include a bed (the body), headstock (the motor mounted on top), tailstock (the vice mounted at the end), tool rest (a platform for holding tools), and speed control. There are two basic types of wood lathes: benchtop lathes which are designed to fit onto a workbench or table; and floor-standing lathes which are designed to be mounted on a solid surface such as concrete or metal.

Wood lathes can be powered either manually or electrically with electric models being available in both AC and DC options. They also come in varying sizes ranging from large industrial-sized machines to small hobbyist models that fit onto a desk or table. Different accessories such as chisels, turning tools, faceplates, and jigs can also be attached to the headstock depending on the nature of the job being done with the machine.

Woodworking projects made using a wood lathe require plenty of skill to produce accurate results with precise patterns or cuts – especially when working with delicate items such as miniature figurines. Knowing how each part of the machine works will help you make better use of your tools and produce top-quality results every time you use your wood lathe.

What types of wood lathes are available?

There are a variety of types of wood lathes available on the market today. The most common type is known as the spindle style, which is made up of a bed, headstock, tailstock, and tool rest. This type of lathe is designed to hold pieces of wood between the headstock and tailstock so that they can be rotated while tools are used to shape and cut them.

Other types include bowl lathes which are designed specifically for shaping large bowls and other round objects; multifunctional lathes with variable speed control; pen-making lathes which are great for making delicate items such as miniature figurines; combination multi-function machines which can be used for both spindle and bowl turning, among other features; and heavy-duty floor models for larger projects such as furniture or architectural pieces.

In addition, many specialized wood lathe tools can be purchased separately such as chisels, gouges, clamps, faceplates, drill bits, and jigs. Different types of wood require different types of cutters or tools to achieve the desired results. It’s important to choose a machine that will work best with your specific project.

How do you use a wood lathe?

Using a wood lathe requires a specific set of skills and knowledge to produce accurate results with precise patterns or cuts – especially when working with delicate items such as miniature figurines.

The first step is to prepare your workpiece, which means making sure it’s the right size and shape for the project. Depending on the nature of the work, you may need to cut it to size, sand it down, or even join two pieces together. Once it’s ready, mount it onto the headstock (motor) and tailstock (vice) of the machine.

Then you can start turning. Place your chosen tool into the tool rest and adjust its height so that it’s level with the wood surface. Turn on the motor at a low speed to begin with so that you can get used to how the machine works before increasing to higher speeds as needed. You should also be aware of kickback – where the tool suddenly grabs hold of the spinning wood – as this could be dangerous if not handled properly.

Once you’re happy with how things are going, use your tools to achieve decorative or practical shapes in your wood. Make sure you frequently check for accuracy and smooth out any rough edges before removing it from the lathe when you’re finished. With practice comes more confidence in using a wood lathe safely and effectively.

What is the difference between a midi lathe and a mini lathe?

The primary difference between mini and midi lathes is size and capacity. Mini wood lathes are typically used for small projects with less complex designs, such as pens or jewelry boxes. They tend to be smaller in overall size and feature reduced capacity; they are also the least expensive of the main types of wood lathe machines.

A midi wood lathe, on the other hand, is larger and comes with greater capacity. They are well-suited for more demanding projects with higher precision requirements, such as chairs, bowls, and spindles. Midi wood lathes tend to be more expensive than mini lathes, however, they offer more flexibility for a variety of projects.

How do you sharpen wood lathe tools?

Sharpening lathe tools is essential to ensuring that they produce accurate and professional results. There are two methods available for sharpening these tools: grinding and honing.

Grinding involves using a focused grinding wheel to sharpen the cutting edge of a tool. This should only be done by experienced users as there is a risk of overheating the metal and damaging it if not done correctly.

Honing is a more user-friendly approach that uses either an abrasive stone or oil-based grits on the cutting edge of the tool instead of a grinding wheel. Honing requires less experience and can be used to maintain a sharp edge between grindings, making it often more suitable for novice woodworkers than grinding.

Make sure to sharpen your tools periodically – especially after periods of heavy use – to produce accurate results and keep them safe from damage.

Can you turn wood on a metal lathe?

While metal lathes are designed primarily for machining metal objects, it is possible to use them for wood-turning. Before starting any project, it is important to set up your machine and tooling correctly.

Start by mounting the workpiece on the headstock of the machine and securing it in place with a chuck or jaws. Then adjust the tools to suit, making sure that they are sharpened correctly for an optimal cutting edge. Use slow RPMs, always feed the tools into the material at an angle, and use a light touch to reduce stress on both you and your workpiece.

It is also important to be aware that wood turns differently than metal – depending on the species of wood being used, you may have problems with tear out or deformation if too much pressure is applied – so take your time and stick to low RPMs until you become more comfortable using the lathe in this way. With patience and practice, you should find turning wood on a metal lathe achievable!

What size wood lathe should I get for my shop?

Choosing the right wood lathe is an important decision when setting up your shop. The size of the wood lathe that you need will depend on the types of projects that you are planning to work on.

If you are primarily working with smaller pieces or turning pens and spindles, then a mini-lathe with 8-12 inches between centers is likely to be a good fit for your needs. For projects such as bowls, platters, and furniture components, a mid-sized lathe with 20-24 inches between centers is recommended.

Finally, if you are looking to turn larger projects such as bedposts or table legs then you should look for a full-sized lathe with 30-40 inches between centers. Knowing what type of projects you want to make will help guide your choice of which size wood lathe is best for your shop.

What type and size of tools can I use to shape pieces on a wood lathe?

Shaping pieces on a wood lathe requires the use of specific tools and your choice of tool type and size will depend on the project that you are working on.

For basic spindle turning such as pens and small bowls, a pair of standard parting tools, skew chisels, round nose scrapers, and spindle gouges should suffice. For larger furniture components such as legs or posts, more specialized cutters are required to achieve a professional finish; including roughing gouges, bowl gouges, fluters, spindle master gouges, and bent scrapers.

The size of your tools should be appropriate for the size of your workpiece – small tools will provide better control when working with smaller items while larger tools are necessary for producing shapes in larger projects. With some practice, you should be able to select the right tool size and type to get the desired results from your wood lathe.

How much power is needed to operate a wood lathe?

The amount of power needed to operate a wood lathe depends on the size and type you choose. Smaller, mini-lathes typically run on 1/4-1/3 HP motors, whereas mid-sized and full-sized lathes can range from 1 to 7.5 HP.

When selecting a new lathe for your shop, it is important to consider the types of projects that you are looking to make and how much power is available in your shop or garage. If you primarily plan on working with smaller items then a lower-powered motor should suffice; however, if you’re planning larger projects then you may need to invest in a more powerful machine.

In addition, check to see what type of speed control system is available on the model you are choosing. Some machines have manual belt changing while others have digital speed control systems that allow you to precisely adjust the rotation speed of your wood lathe according to the needs of your workpiece.

What safety measures should I take when using a wood lathe?

Working with a wood lathe can be both rewarding and enjoyable, however, it is important to take the necessary safety measures to ensure that you are working in a safe environment.

The most important safety precaution to take when using a wood lathe is wearing appropriate protective gear such as safety glasses or goggles, ear protection, and possibly a face shield. Also be sure to wear long sleeves, close-toed shoes, and gloves while operating your lathe – this will help prevent any cuts or burns from flying debris, which could occur when pieces of wood break off during the turning process.

Finally, always make sure that your workspace is clean and well-lit before beginning any project. This will help you maintain concentration while also reducing the risk of an accident taking place due to poor visibility or obstacles in the path of your work.

Are there any specific techniques to keep in mind when using the tool rest or banjo of the wood lathe correctly?

When using a wood lathe, there are a few key techniques to keep in mind when using the tool rest or banjo correctly. First of all, it is important to always make sure that the rest or banjo is properly positioned before beginning any turning project. This will ensure that it is close enough to the workpiece without being too close; otherwise, it can cause potential friction and damage to your tools.

Secondly, be sure to adjust the height of the tool rest or banjo when you switch between different sizes or shapes of workpieces. This will help maximize control while also allowing you to maintain good sightlines as you work with your workpiece.

Finally, use a light touch when placing and adjusting your tools on the tool rest or banjo – this will help minimize wear and tear on both pieces of equipment so that they last for years to come.

Choosing the Best Wood Lathe for You

After having gone through our analysis and compared the five wood lathes we believe are best for your needs, it’s time to make a purchase.

No matter which one you choose, each of these 5 wood lathes has the perfect combination of quality, performance, and value for money that other wood lathes lack.

You will be happy with any product you select from this list.

We hope that we were able to help simplify your search by presenting this data in an organized fashion so that you can make an informed decision.

Now all that is left for you to do is click the links provided to check out prices on Amazon and order yours today to get started on your journey of crafting beautiful custom pieces of artwork!