Best Planer – Say Goodbye to Bumpy Boards

Do you hate looking at wooden boards that are full of splits, cracks, and bumpy surfaces?

Have you been searching for the best planer to get those wood pieces back into shape?

Well say goodbye to all those rough edges, because we’ve got the solution right here!

Whether you’re a DIY enthusiast or a professional woodworker, we have everything you need to know about finding your ideal planer and transforming any wooden board into something that looks as smooth as glass.

Keep reading to find out more!

Looking for a smaller option?

Check out our picks for the best benchtop thickness planers!

How We Choose the Best Wood Planers

Are you ready for some wood planer wisdom?

Let me tell you how we picked the best of the best for our product review article.

First, we dug deep into the woodwork community, talking to woodworking pros and hobbyists alike.

We asked them which planers they couldn’t live without, which ones delivered on their promises, and which ones fell short.

We also scoured the internet for customer reviews and ratings to get a sense of which planers were the real deal.

And after all that research, we were able to narrow down our list to these top wood planers that will have you planing like a pro in no time.

Best Fixed-Table Planer

Grizzly Industrial G0890 – 15″ 3 HP Fixed-Table Planer

Key Features

- 3 HP motor spins blades at 5,200 RPM

- 16 or 28 feet per minute (fpm) feed rates

- 15″ max board width

- 1/8″ max depth of cut

Why It’s a Great Choice

Do you want a planer powerful enough to make an impression that even a grizzly would be proud of?

Look no further than the Grizzly Industrial Fixed-Table Planer!

This 15″ beauty is packed with big features, like its reliable 3 HP motor and 5200 RPM, 3-HSS knife cutter head.

Plus, the 2-speed gearbox keeps your woodworking moving at either 16 or 28 FPM for either a smooth finish or high productivity.

But what makes the Grizzly Industrial Planer unique is its fixed table height, sure to make life efficient in any production setting.

Never worry about juggling between up and down; your planing will stay consistent every time.

And if you’re aiming for extra precision, the headstock sits atop a sturdy four-column support accompanied by easy handwheel height adjustment thanks to twin gas struts on either side.

So when you need to create something more than just an impression of excellence—you need results— trust nothing other than the Grizzly Industrial Fixed-Table Planer!

Perfect for DIYers and pros alike, this is sturdy machinery built to last!

Best Benchtop Thickness Planer

DEWALT 13-Inch Benchtop Planer (DW735)

Key Features

- 15 amp motor spins cutterhead at 10,000 RPM

- 96 or 179 cuts per inch (CPI) feed rates

- 12-1/2″ max board width

Why It’s a Great Choice

The DEWALT 13-Inch Benchtop Thickness Planer is the perfect tool for anyone who’s looking for accurate, detailed woodworking projects.

With a powerful 15-AMP, 20,000 RPM motor that cuts with ease even through thicker materials, this planer will be your go-to tool whenever you need precision cutting.

Not only that but with a three-straight-knife cutter head, you’ll get an extra long life out of these blades – 30 percent longer than usual!

To top it off, the two-speed gearbox allows users to choose different feed speeds to further customize their project.

Ready to take on the toughest tasks?

This machine has you covered – a fan-assisted chip ejection system vacuums chips straight off of the cutter head and into oblivion (seriously, never seen again).

Take your woodworking projects from drab to fab with this DEWALT Planer!

Best Benchtop Planer on a Budget

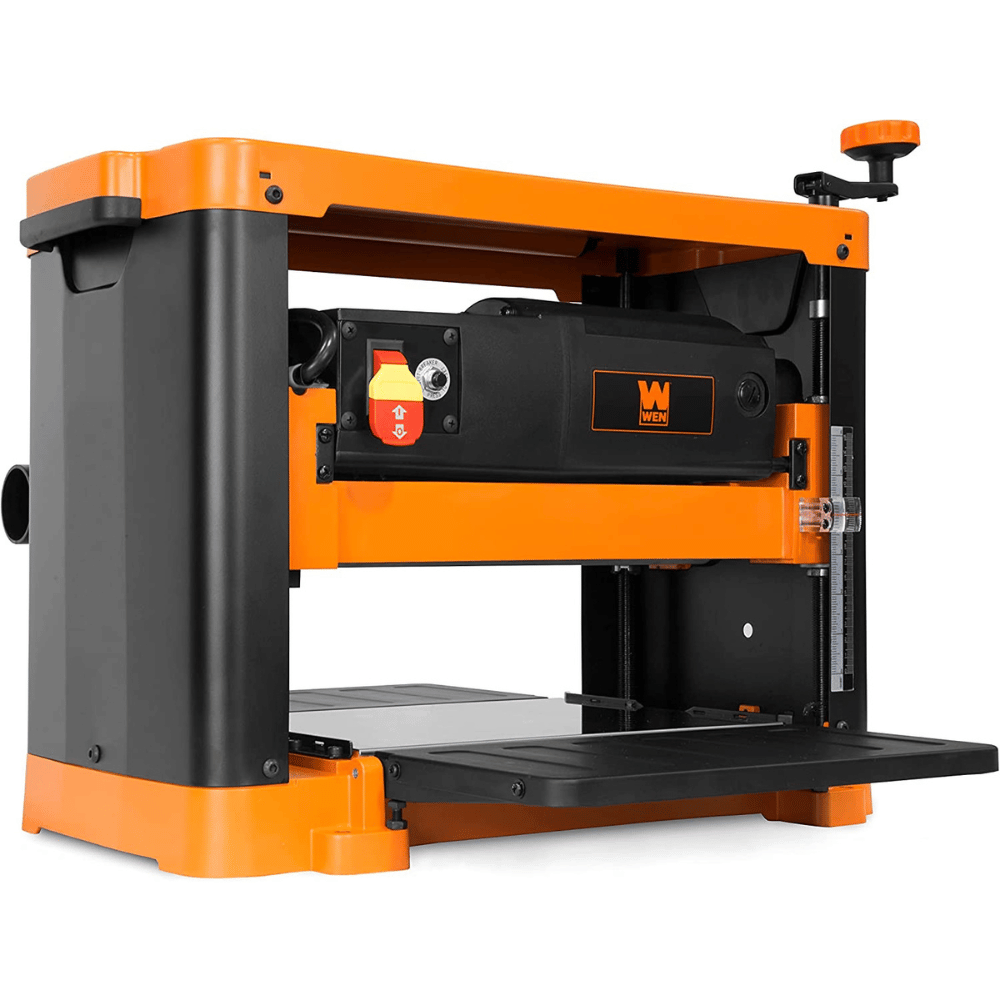

WEN 12.5-Inch Benchtop Thickness Planer (PL1252)

Key Features

- 15 amp motor provides 20,000 cuts per minute

- 26 fpm feed rate

- 12-1/2″ max board width

- 1/8″ max depth of cut

Why It’s a Great Choice

Calling all makers and DIYers!

This WEN 12.5-Inch Benchtop Thickness Planer is here to revolutionize your work and make it easier than ever.

Finding the perfect boards for your projects just got a lot easier- with this planer, you can plane boards up to 6 inches thick and 12.5 inches wide!

Wowzers, that’s some impressive power.

Every board will be cut at perfection, as the 15 Amp motor generates 20,000 cuts per minute at an ultra-fast feed rate of 26 feet per minute.

Plus, with two reversible 12.5-inch SK5 straight knives included (model BP122K), your life will be made easier right out of the box.

And not to mention, you have complete control over the depth of each pass – adjust it from 0 to 1/8th of an inch with ease.

With that kind of precision and power at your fingertips, what are you waiting for?

Get ready to make like a pro with WEN’s portable planer!

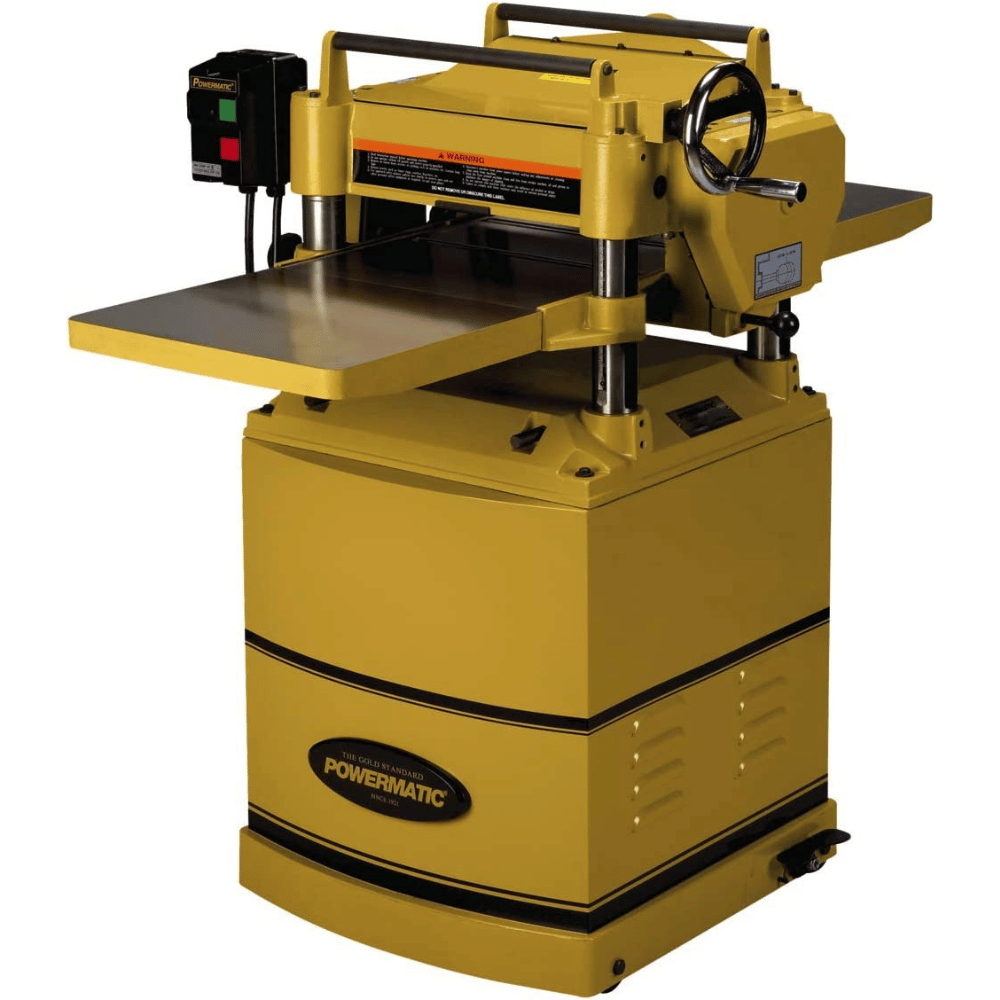

Best Helical Cutter Head Planer

Powermatic 15-Inch Helical Head Planer (1791213)

Key Features

- 3 HP motor

- Dual feed rates

- 14-7/8″ max board width

Why It’s a Great Choice

Ready to level up your woodworking game?

Get the Powermatic 15-Inch Helical Head Planer, the newest addition to a wide selection of professional-grade equipment.

We know you won’t settle for anything less than the best when it comes to your tools, and with 74 four-sided carbide inserts, you can be sure that this planer will handle all your projects with smoothness and efficiency.

Besides superior cutting and milling performance, there are many other great features such as an angled dust chute equipped with a 4″ port for efficient chip & dust collection.

Plus the three v-belts help ensure maximum power is transferred to the cutter head.

And don’t forget about the large, cast iron handwheel which allows you to easily adjust and position your table quickly!

The two-speed gearbox even has an automatic chain tensioner so it can continuously deliver nothing but peak performance no matter what challenges come it’s way.

Trust us – this Powermatic 15-Inch Helical Head Planer is guaranteed to elevate your DIY or professional project results!

Best Wood Thickness Planer for Reducing Snipe

JET JWP-15BHH 15-Inch Helical Cutterhead Planer (722155)

Key Features

- 3 HP motor spins blades at 5,200 RPM

- 16 or 20 feet per minute (fpm) feed rates

- 15″ max board width

- 1/8″ max depth of cut

Why It’s a Great Choice

Get ready to make your DIY dreams come true with the JET JWP-15BHH 15-Inch Helical Cutterhead Planer.

This powerful tool will transform any project you have in mind, and there’s nothing this planer can’t do!

The helical cutter head consists of 48 staggered carbide knives that are custom engineered to align themselves effortlessly – no adjustment necessary.

By providing consistent upward pressure on the cutter head, the Precision Air Strut System (PASS) eliminates snipe and provides a superior finish.

Plus, its dual infeed speeds of 16 or 20 FPM allow for ideal cutting efficiency!

Not only does the JET JWP-15BHH cut like a pro, but it also performs like one too.

The heavy-duty, precision-ground cast iron table and four-post design give maximum control and support – you won’t know how much better things can get until you try it yourself!

Plus, working with this tool is quieter than ever before.

It’s like doing all the work without making half the noise usually associated with these kinds of projects – no more waking up the neighbors in the middle of the night!

To sum it up: whether you’re a DIYer or a professional looking for optimal cutting performance, the JET JWP-15BHH Helical Cutterhead Planer is an absolute must-have.

No other product on the market can boast such efficient snail shells (the helical cutter head)!

Now that’s something to write home about!

Buyer’s Guide to the Best Wood Planers

Are you stumped by the ins and outs of wood planers?

Don’t worry, we’ve got you covered!

We’ve compiled a list of frequently asked questions about these trusty tools to help clear up any confusion.

From understanding the different types of planers to tips on how to maintain them, we’ve got the answers you’re looking for.

So sit back, grab your notebook, and let’s dive into the world of wood planers!

What is a wood planer?

A wood planer is a power tool used to shave, smooth, and straighten rough or uneven surfaces on a piece of wood. The thickness planer uses a rotating cutting head with multiple blades that remove thin layers of wood as the board is passed through the machine. The depth of the cut can be adjusted, allowing the user to control the amount of material removed and the final thickness of the board. Thickness planers are commonly used in woodworking shops for creating smooth, flat surfaces on rough-cut lumber, preparing boards for jointing, and reducing the thickness of boards to a precise size.

What are the different types of wood planers?

There are several different types of wood planers available, each designed for specific woodworking tasks. Some common types of thickness planers include:

- Handheld Planers: These are small, portable planers that are operated by hand. They are ideal for small-scale projects or planing hard-to-reach areas.

- Benchtop Planers: These are larger, stationary planers that sit on a workbench or table. They are capable of planing wider and thicker boards than handheld planers.

- Portable Thickness Planers: These are specialized benchtop planers that are used to reduce the thickness of boards to a precise size and can be easily moved between jobsites.

- Jointer Planers: These are combined machines that include a jointer and a planer in one unit. They are ideal for jointing and planing boards in a single pass.

- Drum Sanders: While not technically planers, drum sanders are machines that can be used to sand flat surfaces of boards to a precise thickness.

- CNC Routers: Computer Numerical Control (CNC) routers are advanced machines that use a computer program to control the movement of the cutting head. These machines are capable of very precise cuts and can be used for complex woodworking projects.

What should I look for when buying a wood planer?

When buying a wood planer, there are several factors to consider to ensure that you get a tool that meets your needs. Some things to look for include:

- Size and Capacity: Consider the size and thickness of the boards you’ll be planing and make sure the planer can accommodate them.

- Power and Speed: Look for a planer with a powerful motor and high cutting speed for efficient material removal.

- Cutting Depth: Make sure the planer can adjust the cutting depth to achieve the desired thickness of the board.

- Blade Quality: The quality and sharpness of the blades are crucial for achieving a smooth finish. Look for planers with high-quality, durable blades.

- Dust Collection: Wood planers produce a lot of sawdust, so look for a planer with an effective dust collection system to keep your workspace clean.

- Ease of Use: Look for a planer that is easy to operate and adjust, with intuitive controls and clear instructions.

- Brand and Reputation: Consider the brand and reputation of the manufacturer, as well as customer reviews and ratings, to ensure you are buying a quality product.

- Price: Planers can range in price from affordable to high-end, so determine your budget and look for a planer that offers good value for the money.

What is the difference between a thickness planer and a jointer?

A thickness planer and a jointer are both woodworking machines that are used to prepare rough lumber for use in a project, but they have different functions.

A jointer is used to straighten and square the edges and faces of boards. It removes small amounts of wood from the surface of a board to make it flat and smooth, creating a straight edge that can be joined to other boards. Jointers are especially useful for creating flat surfaces and removing saw marks from rough lumber.

On the other hand, a thickness planer is used to reduce the thickness of a board to a precise size. It uses a cutting head with multiple blades to remove thin layers of wood from the surface of a board, creating a smooth and even thickness throughout. Thickness planers are useful for creating uniform boards for furniture or construction projects.

In summary, a jointer is used to prepare the edges and faces of boards for joining, while a thickness planer is used to reduce the thickness of boards to a precise size. While they serve different functions, both machines are important tools for preparing rough lumber for woodworking projects.

How do I use a wood planer?

Using a wood planer can seem intimidating at first, but with a little practice, it can become an essential part of your woodworking toolkit. Here are the basic steps for using a wood planer:

- Prepare your workspace: Make sure your work area is clean and clear of clutter. Set up your wood planer on a sturdy surface, such as a workbench.

- Adjust the planer: Adjust the cutting depth to the desired thickness of the board. Make sure the blades are sharp and securely in place.

- Turn on the planer: Turn on the planer and wait for it to reach full speed before feeding the board through.

- Feed the board through the planer: Hold the board firmly with both hands and slowly feed it into the planer. Keep your hands a safe distance from the blades and be sure to keep the board flat against the planer bed as you feed it through.

- Repeat until desired thickness is achieved: After the first pass, check the thickness of the board and adjust the cutting depth if necessary. Feed the board through the planer again until you achieve the desired thickness.

- Turn off the planer: After you’re finished planing, turn off the machine and wait for the blades to stop spinning before removing the board.

- Clean up: Use a brush or vacuum to clean up any sawdust or debris left behind by the planer.

With these basic steps, you’ll be on your way to using a wood planer like a pro in no time!

What are some common problems I might encounter when using a wood planer?

Wood planers are powerful tools that can be very effective at smoothing and shaping wood, but like any tool, they can present certain challenges. Here are some common problems you might encounter when using a wood planer and how to address them:

- Tearout: Tearout is when the wood fibers are lifted out of the surface of the board, creating a rough and uneven finish. This is often caused by dull or improperly adjusted blades. To address tearout, try sharpening the blades or adjusting the cutting depth.

- Snipe: Snipe is when the planer cuts deeper at the beginning or end of a board, leaving a noticeable indentation. This is often caused by uneven pressure on the board or an improperly adjusted infeed or outfeed roller. To prevent snipe, try supporting the board at both ends while feeding it through the planer, and adjust the infeed and outfeed rollers if necessary.

- Uneven surface: If your planed surface is not smooth and even, it could be caused by an uneven board or an improperly adjusted planer bed. Make sure the board is properly supported and adjust the planer bed to ensure it is level and parallel to the cutting head.

- Clogging or poor dust collection: Wood planers generate a lot of sawdust, so it’s important to have an effective dust collection system in place. If your planer is clogging or not collecting dust properly, try cleaning the collection bag or filter, and make sure the dust chute is not blocked.

By being aware of these common problems and taking steps to address them, you can get the most out of your wood planer and achieve a smooth and professional finish on your woodworking projects.

How do I sharpen the blades on a wood planer?

Sharpening the blades on a wood planer is an important part of maintaining the machine’s performance and achieving a smooth finish on your woodworking projects. Here’s a general guide to sharpening the blades on a wood planer:

- Remove the blades: Before you begin, make sure the planer is unplugged and the blades are safely removed from the machine.

- Clean the blades: Use a wire brush or steel wool to remove any rust or debris from the blades. If the blades are heavily damaged or worn, you may need to replace them instead of sharpening them.

- Secure the blades: Use a blade-holding jig or vice to secure the blades in place for sharpening. Make sure the blades are level and securely in place.

- Use a sharpening stone: Using a sharpening stone or honing guide, run the blade over the stone at a consistent angle, applying light pressure. Be sure to maintain the same angle throughout the sharpening process.

- Check for sharpness: After sharpening, check the blade’s sharpness by running a piece of paper or cardboard over the blade. If the blade is sharp, it should cut the paper cleanly without tearing or snagging.

- Reinstall the blades: Once the blades are sharp, reinstall them in the planer according to the manufacturer’s instructions.

Keep in mind that this is a general guide, and the exact process for sharpening the blades on your specific wood planer may vary. Be sure to consult the manufacturer’s instructions and follow all safety precautions when sharpening the blades.

How often should I sharpen the blades on a wood planer?

The frequency with which you should sharpen the blades on a wood planer can vary depending on how often you use the machine and the type of wood you are planing. However, a good rule of thumb is to sharpen the blades after every 10 to 15 hours of use, or when you notice that the planer is not producing a smooth and even finish.

Keep in mind that this is just a general guideline, and the actual frequency of blade sharpening can vary depending on the specific model of your planer, the type of blades you are using, and the conditions in which you are using the machine. If you are unsure about when to sharpen your planer blades, consult the manufacturer’s instructions or contact a professional for guidance.

In addition to regular blade sharpening, it’s important to perform regular maintenance on your wood planer to keep it running smoothly and prevent damage to the blades. This may include cleaning the machine, lubricating moving parts, and checking for signs of wear or damage. By keeping your wood planer well-maintained and properly sharpened, you can ensure that it continues to perform at its best and produce high-quality results on your woodworking projects.

Can I adjust the depth of cut on a wood planer?

Yes, most wood planers allow you to adjust the depth of cut to achieve the desired thickness of your wood. The exact method for adjusting the depth of cut may vary depending on the model of your planer but typically involves turning a dial or adjusting a lever that controls the height of the cutting blades.

Before adjusting the depth of cut on your wood planer, make sure the machine is turned off and unplugged. Then, consult the manufacturer’s instructions for your specific model to determine the correct method for adjusting the depth of cut. Some planers may also have a scale or gauge that allows you to set the desired thickness more precisely.

When adjusting the depth of cut, it’s important to make small adjustments and test the machine frequently to ensure you are achieving the desired thickness without taking off too much material at once. By taking care when adjusting the depth of cut on your wood planer, you can achieve precise and consistent results on your woodworking projects.

How do I prevent snipe when using a wood planer?

Snipe is a common issue that can occur when using a wood planer, which refers to an uneven cut or gouge that appears at the beginning or end of a board. Fortunately, there are several steps you can take to help prevent snipe and achieve a smooth, even finish on your woodworking projects:

- Support the boards: When feeding boards into the planer, make sure to support them at both the infeed and outfeed ends to prevent them from tipping and causing snipe.

- Adjust the infeed and outfeed tables: Some wood planers allow you to adjust the height of the infeed and outfeed tables to minimize snipe. Consult the manufacturer’s instructions for your specific model to determine the correct method for adjusting these tables.

- Take light cuts: Rather than trying to remove a large amount of material at once, take light cuts and gradually reduce the thickness of the board. This can help prevent snipe and produce a smoother finish.

- Use a sacrificial board: Placing a scrap board at the beginning and end of the piece you’re planing can help prevent snipe by providing additional support and reducing the likelihood of the blades digging into the board.

- Keep the blades sharp: Dull blades can increase the risk of snipe, so be sure to keep your planer blades sharp and well-maintained.

By following these tips and taking care when using your wood planer, you can help prevent snipe and achieve a smooth, even finish on your woodworking projects.

Choosing the Best Wood Planer for You

We hope this article has provided you with some helpful insight in your search for a wood planer.

Each one of these options represents quality construction that can help you create beautiful woodworking projects.

Whether you’re a beginner, homeowner, or experienced woodworker, all of these wood planers are dependable and easy to use.

Check out the reviews and if you still can’t decide which one is right for you, try them all – no judgment here!

After all, who doesn’t love having too many tools?

Don’t miss out on these great deals – head over to Amazon and click the links above to check prices now.

Now go forth and let your creativity flow!