Chop Saw vs Miter Saw – How Do You Know Which You Need?

When it comes to power tools, there’s no shortage of options to choose from. Two popular tools you might come across (and may have even thought were the same thing) are the chop saw and the miter saw. Understanding the differences between these two tools is essential to ensure you select the right one for your woodworking or construction projects. So, let’s dive into the world of the chop saw vs miter saw debate!

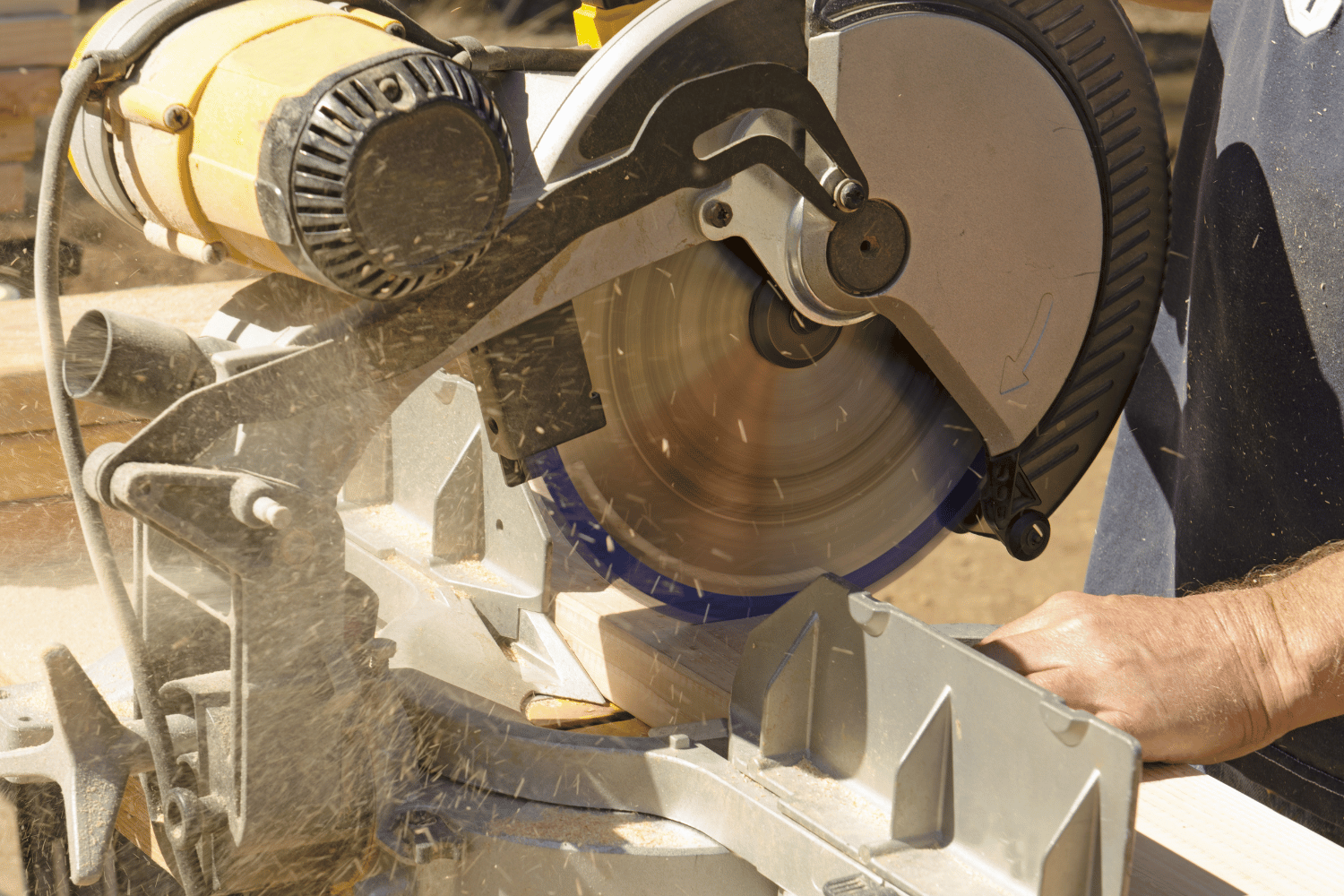

A chop saw, also known as a cut-off saw, is a powerful tool primarily designed to cut metal materials on a perpendicular angle. It typically features a circular blade that moves up and down to create precise cuts. They are known for their robust construction, making them suitable for heavy-duty applications. They are commonly used in construction sites, metal fabrication, and woodworking shops.

On the other hand, a miter saw is a versatile cutting tool used for making accurate angled cuts. It features a circular blade mounted on a pivoting arm, allowing you to make precise crosscuts, miters, and bevels. They are particularly useful for trim work, framing, and making precise angled cuts for joinery. With a miter saw, you can achieve angled cuts with precision and ease.

Understanding the differences between these two tools is crucial because they excel in different areas. A chop saw is all about power and strength, making it ideal for heavy-duty applications. Its sturdy build and powerful motor can handle tough materials and repetitive cuts, making it a favorite among professionals. On the other hand, a miter saw focuses on accuracy and versatility. With its ability to make precise angled cuts, it’s the go-to tool for tasks that require precision and finesse.

In the following sections, we’ll expand on the chop saw vs miter saw debate by exploring the features, capabilities, and limitations of both saws. We’ll also discuss factors to consider when choosing between the two, and provide examples of projects where each tool shines. So, whether you’re a DIY enthusiast or a professional woodworker, stay tuned to discover the best tool for your next cutting adventure!

Understanding Chop Saws

Definition and Features of a Chop Saw

Let’s start by delving into the world of chop saws. A chop saw, also known as a cut-off saw, is a powerful tool designed for metal cutting at a perpendicular angle, but also can be used on wood or plastic. It is equipped with a circular blade that moves up and down to create clean and precise cuts. One of the notable features of a chop saw is its robust construction, which enables it to withstand heavy-duty tasks.

Most chop saws are stationary tools that can be mounted on a workbench or used with a separate stand. They are often powered by electricity, although there are also models available that use compressed air or hydraulic power. The blade size of a chop saw can vary, with common sizes ranging from 10 to 14 inches in diameter. Some models even have adjustable blade speeds to accommodate different materials and cutting requirements. With their common use of metal cutting, they often come equipped with abrasive cutting wheels or abrasive blades suitable for those materials.

Applications and Common Uses

Chop saws find their application in a wide range of industries and projects. In construction sites, they are frequently used for cutting metal pipes, rods, and structural beams. Metal fabrication shops rely on chop saws to make precise cuts in steel, aluminum, and other metals. Woodworkers also utilize chop saws to cut lumber, plywood, and other wooden materials accurately. Additionally, a chop saw is valuable in the automotive and plumbing industries, where it is employed for cutting various materials to specific lengths.

Key Characteristics and Limitations

One of the key characteristics of a chop saw is its sheer power. The strong motor and sturdy build of these saws allow them to handle demanding tasks and heavy materials with ease. They excel in making quick perpendicular cuts, making them ideal for projects that require efficiency and productivity.

However, it’s essential to be aware of some limitations. Chop saws are primarily designed for straight cuts and are less suitable for tasks that require angle cuts or intricate shapes. They also have limited versatility compared to other cutting tools. While they are excellent for repetitive and heavy-duty cuts, they may not offer the same precision and flexibility as other saw types.

Understanding Miter Saws

Definition and Features of a Miter Saw

Now, let’s shift our focus to miter saws, which are versatile cutting tools that excel at making accurate angled cuts. A miter saw features a circular blade mounted on a pivoting arm. This design allows the saw blade to rotate and tilt, enabling precise crosscuts, miter cuts (angle cuts across the width of a material), and bevel cuts (angled cuts through the thickness of a material).

Miter saws come in different variations, including standard miter saws, compound miter saws, and sliding miter saws. Standard miter saws provide the ability to make precise angled cuts, while compound miter saws can also tilt the blade for bevel cuts, offering increased cutting versatility. Sliding miter saws have a sliding mechanism that allows the blade to move forward and backward, enabling the saw to cut wider workpieces.

Applications and Common Uses

A miter saw is commonly used in various industries and projects. Woodworkers rely on miter saws for tasks such as trim work, crown molding installation, picture framing, and making accurate angled cuts for joinery. They are also popular among carpenters, furniture makers, and contractors who need to make precise cuts for door frames, baseboards, and other detailed woodworking projects.

In addition to woodworking, a miter saw can be utilized for cutting materials like plastic and non-ferrous metals. This makes them suitable for projects in the fields of DIY home improvement, interior design, and general construction.

Key Characteristics and Limitations

One of the key characteristics of a miter saw is its precision. The ability to make accurate angled cuts at various angles, combined with the saw’s stable cutting platform, allows for consistent and clean cuts. Miter saws also offer cutting versatility, especially compound and sliding compound models, which enable both miter and bevel cuts.

However, it’s important to consider the limitations of miter saws. Unlike chop saws, which are designed for straight cuts, miter saws may have limitations in terms of cutting capacity. The size of the workpiece that can be cut is determined by the blade size and the sliding capacity (for a sliding compound miter saw). Additionally, miter saws may not be the most suitable choice for heavy-duty cutting tasks or cutting through thick materials.

It’s worth noting that miter saws excel at making precise cuts at specific angles, but they may not be as efficient for repetitive perpendicular cuts as a chop saw. Depending on your project requirements, you may need to consider the specific characteristics and limitations of miter saws to ensure they align with your needs.

Differences Between Chop Saws and Miter Saws

Now that we have a good understanding of chop saws and miter saws individually, let’s compare the key differences between the two and explore which tool might be more suitable for specific projects.

Cutting Capacity

One significant difference between chop saws and miter saws lies in their cutting capacity. Chop saws are designed for straight cuts and are known for their ability to handle thick and tough materials with ease. They have larger blade sizes, typically ranging from 10 to 14 inches, allowing them to cut through thicker workpieces.

On the other hand, miter saws excel at making precise angled cuts. While they may not have the same cutting capacity as chop saws, their versatility lies in the ability to cut materials at various angles and create complex shapes. Miter saws are typically used for cutting narrower workpieces, such as trim boards and moldings.

Cutting Accuracy and Precision

When it comes to cutting accuracy and precision, miter saws take the lead. With their adjustable angles and stable cutting platforms, miter saws allow for precise and repeatable cuts. They are particularly valuable for tasks that require precise angles, such as mitered corners or beveled edges.

While chop saws can make straight cuts efficiently, they may not offer the same level of accuracy and precision as miter saws. Their primary strength lies in their power and speed for straight cuts, rather than intricate angled cuts.

Bevel and Miter Angles

Bevel and miter angles refer to the cutting angles that can be achieved with the respective saws. Miter saws are designed to make both miter cuts (across the width) and bevel cuts (through the thickness) simultaneously. This makes them ideal for projects that require angled cuts, such as crown molding installation or creating precise joinery.

On the other hand, chop saws are typically limited to straight cuts and do not have the ability to make adjustable bevel or miter cuts. Their focus is on making quick and efficient straight cuts without the versatility of angled cuts.

Versatility and Specialized Functions

In terms of versatility, miter saws have the upper hand. They offer a wide range of cutting options, including miter cuts, bevel cuts, and compound cuts (combining miter and bevel angles). Some miter saws even have sliding mechanisms that allow for cutting wider workpieces. This versatility makes them suitable for various woodworking and construction projects.

Chop saws, on the other hand, are specialized tools designed specifically for making straight cuts in tough materials. While they excel at repetitive straight cuts, they may lack the versatility to tackle angled or specialized cuts.

Portability and Size

When it comes to portability, chop saws and miter saws differ significantly. Chop saws are typically bulkier and heavier, designed to be stationary tools mounted on a workbench or used with a separate stand. They are less portable and not as convenient to transport from one job site to another.

Miter saws, on the other hand, are often more compact and lightweight, making them easier to transport and maneuver. This portability factor makes miter saws a popular choice for contractors and DIY enthusiasts who need to move between different locations.

Cost and Value for Money

Cost is another factor to consider when comparing chop saws and miter saws. Generally, chop saws tend to be more affordable than miter saws, especially when considering entry-level or basic models. However, as you move up to more advanced features and larger blade sizes, the prices for both types of saws can increase.

When determining the value for money, it’s essential to consider the specific needs of your projects. If you primarily require straight cuts and work with heavy materials, a chop saw might provide the best value. Conversely, if you need precise angled cuts and versatility, a miter saw would be a worthwhile investment.

By understanding the differences in cutting capacity, accuracy, angles, versatility, portability, and cost, you can make an informed decision when selecting between a chop saw and a miter saw for your specific projects.

In the next section, we’ll conclude our comparison and provide some final thoughts on choosing the right tool for your cutting needs.

Choosing the Right Tool for the Job

When it comes to selecting the right tool between a chop saw and a miter saw, several factors should be considered. Let’s explore these factors to help you make an informed decision based on your specific needs.

Factors to Consider when Selecting a Chop Saw or a Miter Saw

- Type of cuts: Consider the types of cuts you need to make. If your projects primarily involve straight cuts in tough materials, a chop saw might be the more suitable choice. However, if you require precise angled cuts or the ability to create complex shapes, a miter saw would be the better option.

- Material and cutting capacity: Evaluate the thickness and hardness of the materials you’ll be working with. Chop saws excel at handling heavy-duty materials, while miter saws are better suited for narrower workpieces. Take into account the cutting capacity and blade size of each tool to ensure it aligns with your project requirements.

- Cutting accuracy and precision: If your projects demand high levels of accuracy and precision, a miter saw is the tool of choice. Miter saws allow for adjustable angles, making them ideal for tasks that require precise cuts at specific angles.

Examples of Suitable Projects for Each Tool

To help you further, here are some examples of projects where each tool shines:

- Chop saw: Chop saws are excellent for construction projects involving cutting metal pipes, rods, or structural beams. They are also favored in metal fabrication shops for making clean cuts in steel or aluminum. Additionally, chop saws are great for woodworking tasks that require repetitive straight cuts in thick lumber or plywood.

- Miter saw: Miter saws are ideal for woodworking projects that involve trim work, crown molding installation, or creating precise angles for joinery. They are commonly used in tasks like cutting baseboards, door frames, or picture frames, where accuracy and versatility are paramount.

Matching the Tool to the Specific Requirements of the Project

Consider the specific requirements of your project and match them to the capabilities of each tool. If you need to make intricate angled cuts or work with narrow materials, a miter saw will be your best bet. On the other hand, if you primarily require quick and efficient straight cuts in heavy materials, a chop saw will suit your needs.

Personal Preferences and Budget Considerations

Your personal preferences and budget will also play a role in your decision. Some individuals may have a preference for the power and robustness of a chop saw, while others may value the precision and versatility of a miter saw. Additionally, consider your budget and weigh the features, capabilities, and quality of each tool to make the most cost-effective choice.

Remember, it’s essential to match the tool to the specific requirements of your project and prioritize the factors that matter most to you, such as cutting capacity, accuracy, versatility, portability, and cost.

Understanding the differences between chop saws and miter saws is crucial for selecting the right tool for your cutting needs. By considering factors such as the type of cuts, material and cutting capacity, cutting accuracy, suitable projects, specific project requirements, personal preferences, and budget considerations, you can confidently choose between a chop saw and a miter saw that best suits your needs.

Final Thoughts

Remember, the right tool for the job ultimately depends on your specific requirements, preferences, and budget. Take into account factors such as cutting capacity, accuracy, versatility, portability, and cost, and weigh them against your project needs to make the best choice.

By selecting the appropriate tool, whether it’s a chop saw or a miter saw, you’ll have the confidence to tackle your projects effectively and achieve the desired results.

So, don’t hesitate to take the time to research, compare, and evaluate your options. Invest in the right tool, and you’ll be equipped to take on any cutting task with ease and precision.

In the end, it’s all about choosing the tool that aligns perfectly with your project requirements. Both chop saws and miter saws can be vital additions to your tool arsenal.v