The Impact Wrench – Harness the Mighty Power

Have you ever encountered a stubborn bolt that simply refuses to budge? Or found yourself grappling with a seemingly endless assembly project, desperately seeking power tools that can effortlessly tighten fasteners? Look no further! Allow us to introduce you to the dynamic world of impact wrenches, the unsung heroes of the tool kingdom.

An impact wrench is a powerful and specialized tool designed to deliver high-torque rotational force with incredible speed. Its primary purpose is to loosen or tighten fasteners such as nuts, bolts, and screws. What sets it apart from traditional wrenches is its unique mechanism that combines rotational force with sudden impacts, allowing it to conquer even the most stubborn and rusted fasteners. While similar to impact drivers, impact wrenches offer much more torque and impact force and can handle much bigger nuts and bolts.

The impact wrench’s importance extends far beyond DIY enthusiasts’ workshops. In fact, it plays a pivotal role in a wide range of industries and applications.

Picture yourself at a bustling mechanic’s garage, where time is of the essence. Impact wrenches are the go-to tools for automotive professionals, effortlessly removing lug nuts, suspension bolts, and other stubborn fasteners. Their rapid and powerful action saves valuable time, enabling mechanics to swiftly complete repairs and get vehicles back on the road.

On construction sites, where heavy-duty tasks and demanding deadlines prevail, impact wrenches come to the rescue. From erecting steel structures to assembling scaffolding, these tools make light work of securing bolts and screws, enhancing efficiency, and ensuring sturdy constructions.

In manufacturing facilities, where precision and speed are vital, impact wrenches play a crucial role in assembly lines. They excel at swiftly tightening fasteners on production equipment, appliances, furniture, and even aircraft components. Their ability to deliver consistent torque with minimal effort significantly boosts productivity and ensures the reliability of assembled products.

Industrial machinery and equipment demand periodic maintenance and repairs. Impact wrenches become indispensable allies in these tasks, swiftly disassembling and reassembling intricate components, saving time, and minimizing downtime in factories and workshops.

The impact wrench’s versatility shines across industries, catering to professionals and DIY enthusiasts alike. Whether you’re an automotive mechanic, a construction worker, or a weekend warrior tackling home improvement projects, having an impact wrench in your arsenal can transform the way you work.

In the following sections, we will delve deeper into the types of impact wrenches available, their key features, and the safety considerations to keep in mind. Get ready to explore the world of impact wrenches and unlock a new level of efficiency and ease in your projects.

Types of Impact Wrenches: Finding Your Perfect Fit

When it comes to impact wrenches, there’s no shortage of options to cater to diverse needs and preferences. Let’s explore three popular types: electric impact wrenches, pneumatic impact wrenches, and cordless/battery-powered impact wrenches.

Electric Impact Wrenches

Electric, or corded impact wrenches are a favorite among many DIYers and professionals alike due to their ease of use and convenience. These powerful tools operate using an electric motor to generate rotational force and impact. Here are some key points to consider:

- How They Work: Electric impact wrenches harness electricity to drive a motor that rotates an internal hammer mechanism. This mechanism delivers torque to the fastener, while the sudden impacts help break stubborn bonds.

- Advantages and Disadvantages: Electric impact wrenches offer several advantages, such as portability, affordability, and ease of maintenance. They don’t require an external power source like pneumatic wrenches and provide consistent power output. However, they may have slightly lower torque capabilities compared to their pneumatic counterparts.

- Common Applications: Electric impact wrenches find their place in a variety of scenarios. From automotive maintenance and repairs to home projects, they excel at tasks like changing tires, removing stubborn bolts, and assembling furniture.

Pneumatic Impact Wrenches

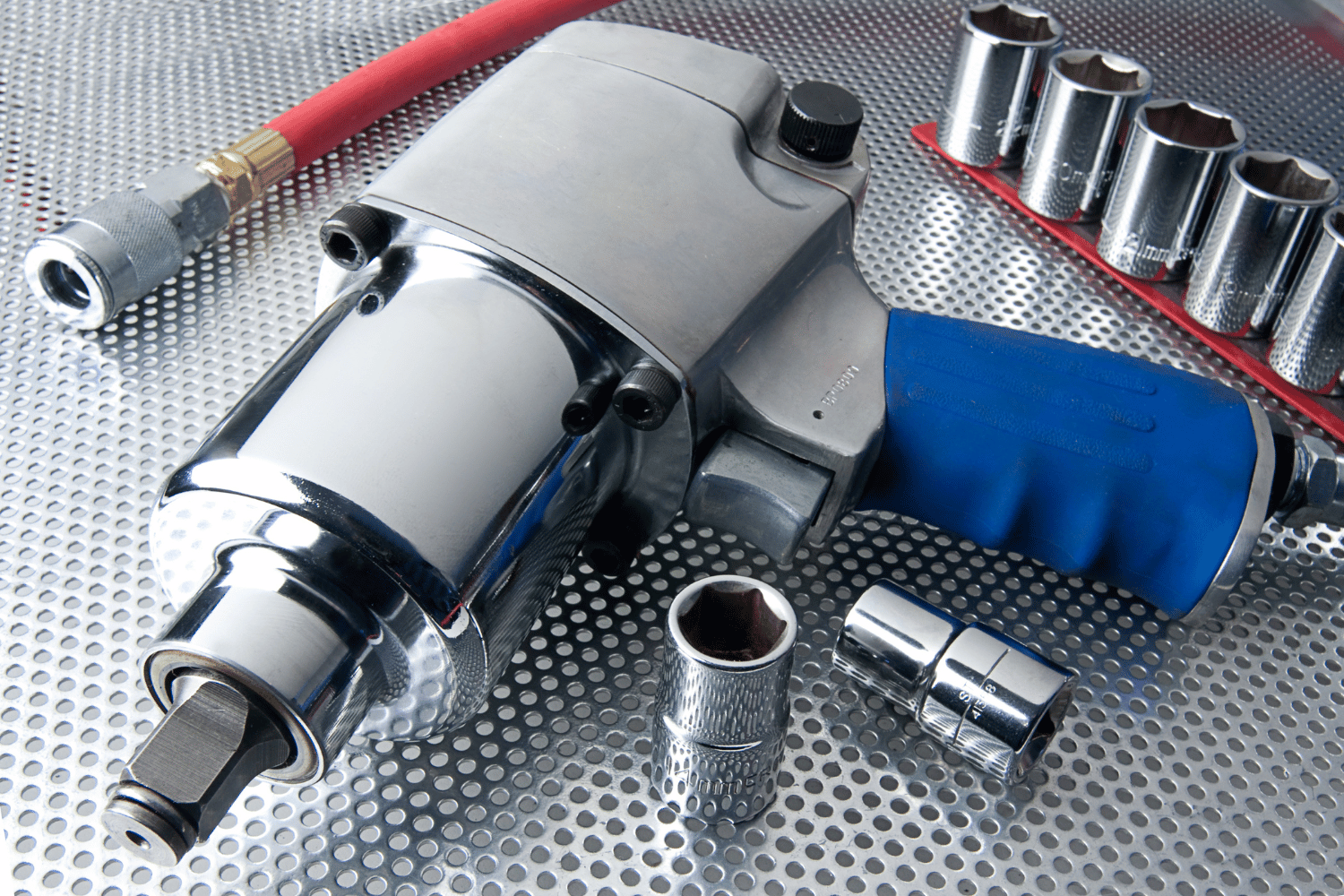

A pneumatic impact wrench, also known as an air impact wrench, is renowned for its exceptional power and reliability. A high torque model like this utilizes compressed air to deliver impressive rotational and impact force. Here’s what you need to know:

- How They Work: Pneumatic impact wrenches rely on compressed air from an air compressor. The air flows through the wrench’s motor, driving the hammer mechanism to create rotational force and powerful impacts.

- Benefits and Drawbacks: Pneumatic impact wrenches are beloved for their unparalleled torque output, making them ideal for heavy-duty applications. They provide consistent power and don’t have the limitations of battery life. However, they require an air compressor and hoses, making them less portable and potentially more expensive to set up initially.

- Typical Applications: Pneumatic impact wrenches shine in industrial settings, such as automotive repair shops, construction sites, and manufacturing plants. They are indispensable for tasks like loosening large bolts, tightening structural elements, and assembly line work.

Cordless/Battery-Powered Impact Wrenches

A cordless impact wrench offers the perfect blend of portability and convenience, allowing users to tackle projects without the constraints of cords or hoses. These tools operate using rechargeable batteries. Let’s explore further:

- Features and Operation: Cordless impact wrenches feature a battery pack that powers an electric motor, generating rotational force and impacts. They often come with adjustable torque settings and may incorporate advanced features like LED lights and ergonomic designs for enhanced user experience.

- Advantages and Limitations: Cordless impact wrenches provide unmatched mobility and versatility. They allow users to work in tight spaces and remote locations without being tethered to power outlets or air compressors. However, their power output may be lower compared to electric or pneumatic counterparts, and they require regular battery charging.

- Popular Applications: Cordless impact wrenches find favor in automotive repairs, construction projects, and home improvement tasks. They excel at tasks such as changing tires, assembling structures, and working in areas where power sources are limited.

With a better understanding of the various types of impact wrenches, you can choose the one that aligns with your specific needs and working environment. Whether you prefer the convenience of electric, the torque of air-powered, or the mobility of cordless, there’s an impact wrench out there ready to tackle your toughest fastening challenges.

Key Features and Considerations: Unleashing the Potential of Your Impact Wrench

When it comes to selecting the perfect impact wrench, understanding key features and considerations is vital. Let’s explore three crucial factors to help you make an informed choice: torque rating, drive size, and power source.

Torque Rating

The torque rating of an impact wrench refers to the maximum rotational force it can deliver. It is a crucial specification that directly influences the tool’s capabilities. Here’s what you need to know:

- Significance of Torque Rating: The torque rating determines the wrench’s ability to loosen or tighten fasteners effectively. A higher torque rating translates to more power, enabling you to tackle larger or stubborn fasteners. It is crucial to match the torque rating to the requirements of your specific tasks.

- Relationship with Capabilities: The higher the torque rating, the more torque the impact wrench can deliver. This allows it to handle a broader range of applications, from light-duty tasks like DIY projects to heavy-duty jobs in automotive, construction, and manufacturing industries.

- Choosing the Appropriate Torque Rating: Consider the types of projects you frequently undertake. If you work primarily on smaller bolts and screws, a lower torque rating may suffice. However, if you tackle larger or more challenging fasteners, opt for a high torque impact wrench to ensure the wrench can handle the task efficiently.

Drive Size

Drive size refers to the size of the square-shaped socket connection on the impact wrench. It is crucial to select the appropriate drive size to ensure compatibility with impact sockets and achieve optimal performance. Here’s what you should keep in mind:

- Importance of Drive Size: Drive size determines the compatibility between the impact wrench and the sockets you use. It ensures a secure and efficient connection, preventing slippage or damage. It is crucial to match the drive size of your impact wrench with the drive size of the sockets you intend to use.

- Common Drive Sizes: The most common drive sizes for impact wrenches are ½-inch, ¾-inch, and 1-inch. Smaller drive sizes like ¼-inch and 3/8-inch are available for lighter tasks or confined spaces. Each drive size has its typical applications, such as automotive repair, construction, or heavy machinery maintenance.

- Matching Drive Sizes to Tasks: Consider the size and torque requirements of the fasteners you will be working with. For example, ½-inch drive impact wrenches are versatile and suitable for a wide range of tasks, while larger drive sizes excel at heavy-duty applications. Ensure your impact sockets match the drive size of your impact wrench for seamless compatibility.

Power Source

The power source of impact wrench models determines their mobility, convenience, and performance. Let’s compare the three primary power sources: electric, pneumatic, and cordless/battery-powered:

- Electric Impact Wrenches: These impact wrenches operate using electricity and are suitable for tasks that require moderate power. They are convenient, often portable, and do not rely on external power sources. However, they may have slightly lower torque compared to pneumatic options.

- Pneumatic Impact Wrenches: Pneumatic impact wrenches utilize compressed air and are known for their exceptional power. They excel in heavy-duty applications, providing high torque output. However, they require an air compressor, limiting their mobility and adding initial setup costs.

- Cordless/Battery-Powered Impact Wrenches: Cordless impact wrenches offer the advantage of mobility and freedom from cords or hoses. They are usually powered by a brushless motor running on a rechargeable battery, making them versatile for various tasks. However, they may have limited battery life and slightly lower power compared to electric or pneumatic alternatives.

Choosing the right power source depends on factors such as portability requirements, power needs, and the availability of power sources in your working environment. Consider your specific needs and select the power source that aligns best with your working style.

By understanding torque rating, drive size, and power source considerations, you can confidently choose an impact wrench that suits your projects and requirements. Whether you’re a professional seeking heavy-duty capabilities or a DIY enthusiast embarking on home improvement ventures, these factors will help unleash the full potential of your impact wrench, making every fastening task a breeze.

Applications and Industries: Where Impact Wrenches Shine

Impact wrenches have earned their reputation as indispensable tools across various industries. Let’s explore some key sectors where these powerful tools play a vital role and the specific applications that showcase their prowess.

Automotive Industry

When it comes to the automotive industry, impact wrenches are the go-to tools for mechanics and automotive enthusiasts alike. The speed, power, and precision they offer revolutionize automotive maintenance and repair tasks. Here’s a glimpse into their automotive applications:

- Lug Nut Removal and Tire Changes: One of the most common uses of impact wrenches in the automotive industry is for swiftly removing lug nuts during tire changes. The torque and impact force delivered by impact wrenches along with features like variable speed triggers make this task a breeze, saving time and effort.

- Suspension and Brake Repairs: Impact wrenches prove invaluable in tackling suspension and brake repairs. They effortlessly handle stubborn bolts and fasteners, making disassembly and reassembly tasks quicker and more efficient.

- Engine and Transmission Work: Whether it’s replacing an engine or working on the transmission, impact wrenches come to the rescue. They facilitate the removal and installation of bolts, ensuring a secure and precise fit.

Construction Industry

Construction sites are bustling with activity, and time is of the essence. Impact wrenches bring their high torque and rapid operation to the construction industry, enhancing productivity and efficiency. Here are some construction tasks where impact wrenches shine:

- Steel Structures and Structural Fastening: Erecting steel structures requires a secure and reliable fastening job. Impact wrenches handle the tightening of bolts and structural elements swiftly and efficiently, ensuring the integrity and stability of the construction.

- Scaffolding Assembly: Impact wrenches simplify the assembly and disassembly of scaffolding systems. With their power, workers can quickly tighten the numerous bolts that hold the scaffolding in place, streamlining the process and ensuring worker safety.

- Concrete Formwork: Impact wrenches aid in fastening the components of concrete formwork systems. From tightening clamps to securing brackets, these tools make the repetitive task of formwork assembly faster and more precise.

Manufacturing and Assembly

In manufacturing and assembly industries, precision and efficiency are paramount. Impact wrenches play a critical role in streamlining production processes and ensuring reliable fastening. Let’s delve into specific applications:

- Aerospace and Aviation: Impact wrenches are vital in aerospace and aviation manufacturing, where safety and precision are of utmost importance. They aid in assembling aircraft components, securing bolts in engine installations, and maintaining airframe structures.

- Furniture Manufacturing: From constructing wooden frames to attaching joints and fasteners, impact wrenches excel in the furniture manufacturing industry. They ensure efficient assembly and reliable structural integrity of furniture pieces.

- Appliance Production: In appliance manufacturing, impact wrenches streamline the assembly of components, such as securing motor brackets, tightening screws, and attaching handles. These tools enhance productivity and ensure consistent quality.

Across these industries, impact wrenches prove their worth by simplifying complex tasks, reducing manual effort, and accelerating project timelines. Their ability to deliver high torque and quick impacts makes them invaluable companions in automotive repair shops, construction sites, and manufacturing facilities.

As you explore the applications of impact wrenches, consider the specific requirements of your industry and the tasks you frequently undertake. With the right impact wrench in hand, you can unleash your full potential and conquer the fastening challenges that come your way.

Safety Considerations: Power with Responsibility

While impact wrenches are powerful tools that can greatly simplify your tasks, it’s essential to prioritize safety during their operation and maintenance. Let’s explore some key safety considerations to ensure a secure and productive work environment.

Proper Handling and Operation

To maximize safety when using an impact wrench, follow these guidelines:

- Body Positioning and Grip: Maintain a stable stance and proper body positioning to ensure balance and control. Keep your feet shoulder-width apart and firmly planted on the ground. Grip the impact wrench securely, using both hands, and avoid awkward or strained positions.

- Appropriate Safety Gear: Protect yourself by wearing the appropriate safety gear. This includes safety glasses to shield your eyes from flying debris, gloves to maintain a secure grip and protect your hands, and hearing protection to minimize noise exposure.

- Hazard Mitigation: Be aware of potential hazards and take necessary precautions. Clear the work area of clutter, ensuring there are no obstructions or tripping hazards. Identify any potential pinch points or entanglement risks and take steps to mitigate them. Also, beware of hot surfaces that may result from prolonged or intensive use.

Maintenance and Inspection

Regular maintenance and inspection of your impact wrench are crucial for ensuring its optimal performance and longevity. Here’s what you should keep in mind:

- Importance of Regular Maintenance: Regular maintenance not only enhances the lifespan of your impact wrench but also ensures its safety and effectiveness. Follow the manufacturer’s guidelines for maintenance intervals and procedures.

- Cleaning and Lubrication: Keep your impact wrench clean and free from debris. Regularly inspect and clean the housing, air vents, and internal components. Additionally, lubricate the impact mechanism and other moving parts according to the manufacturer’s recommendations.

- Periodic Inspection: Perform routine inspections to identify any signs of wear, damage, or loose components. Check the cord or hose for any signs of fraying or damage in electric or pneumatic impact wrenches. Also, inspect the battery and connections in cordless impact wrenches. If you notice any issues, promptly address them to maintain the tool’s safety and performance.

- Calibration and Repairs: Periodically calibrate your impact wrench to ensure its accuracy and consistency. If you notice any significant drop in performance, unusual vibrations, or unusual noise, it’s essential to have your impact wrench inspected and repaired by a qualified professional.

By prioritizing safety through proper handling, using the appropriate safety gear, and adhering to regular maintenance and inspection routines, you can enjoy the benefits of your impact wrench while minimizing the risks associated with its use.

Remember, safety is paramount. Always familiarize yourself with the specific safety recommendations provided by the manufacturer and exercise caution when using an impact wrench. By working responsibly and proactively, you can maintain a safe working environment and make the most of your powerful tool.

Unlocking the Potential of Impact Wrenches

Throughout this article, we’ve delved into the world of impact wrenches, exploring their purpose, types, key features, applications, safety considerations, and more. Let’s recap the main points we’ve covered and reinforce the benefits of these remarkable tools.

Impact wrenches are versatile power tools designed to tackle fastening tasks with speed and precision. They come in various types, including electric, pneumatic, and cordless, each with its unique advantages and considerations. These tools excel in a wide range of industries and applications, from automotive repairs and construction projects to manufacturing and assembly lines.

We’ve discussed the importance of considering key features such as torque rating, drive size, and power source when selecting an impact wrench. Understanding these factors empowers you to choose the right tool for your specific needs, ensuring optimal performance and efficiency.

Moreover, we explored the safety considerations associated with using impact wrenches, emphasizing the significance of proper handling, using the appropriate safety gear, and following regular maintenance and inspection routines. By prioritizing safety, you can mitigate risks and create a secure work environment.

In conclusion, impact wrenches are indispensable tools that revolutionize fastening tasks across a wide range of applications. Their high torque, speed, and precision enhance productivity, save time and effort, and improve overall efficiency. Whether you’re a professional in the automotive, construction, or manufacturing industry or a DIY enthusiast tackling projects at home, an impact wrench is a worthy investment.

As you continue your journey with impact wrenches, remember to explore further, consider your specific needs, and make informed decisions. Research different models, read customer reviews, and consult with professionals if needed. By doing so, you’ll find the perfect impact wrench that aligns with your requirements, enabling you to complete tasks effectively and efficiently.

So, go ahead, unleash the power of an impact wrench, and witness the remarkable difference it makes in your projects. Enjoy the ease, speed, and precision that these tools bring to your fastening endeavors.