How to Use a Metal Lathe: A Beginner Guide

Welcome to the world of metalworking! If you’ve ever been curious about shaping metal into precise and intricate forms, using a metal lathe is a skill worth mastering. In this comprehensive guide, we will walk you through the fundamental steps of how to use a metal lathe safely and effectively.

A metal lathe is a powerful and versatile tool used by machinists and artisans alike. It allows you to turn, bore, thread, and shape metal workpieces with precision and finesse. Whether you’re a student exploring metalworking as a hobby or an aspiring engineer looking to refine your craft, understanding the basics of a metal lathe is an essential foundation.

Throughout this article, we will cover the key components of a metal lathe, the types of operations you can perform, and safety guidelines to ensure you work confidently without compromising your well-being. By the end of this guide, you’ll be equipped with the knowledge and confidence to embark on your metalworking journey, unlocking the potential to create remarkable pieces and bring your ideas to life. So, let’s get started and discover the art of using a metal lathe!

Understanding the Metal Lathe Machine

A metal lathe may seem like a complex machine, but breaking down its key components and understanding the different types can make it much more approachable.

Components of a Metal Lathe

Bed

The bed is the sturdy foundation of the lathe, usually made of cast iron. It provides support and stability to all the other components. The carriage and tailstock slide along the bed’s length, ensuring precise movement during the machining process.

Headstock

Located on one end of the lathe’s bed, the headstock houses the main spindle. It holds the workpiece and rotates it at various speeds to enable cutting. The spindle’s speed can be adjusted to accommodate different materials and cutting operations.

Tailstock

Situated on the opposite end of the headstock, the tailstock helps support the workpiece during machining. It can move along the bed and is equipped with a barrel and a center for holding the workpiece securely in place.

Carriage

The carriage is responsible for holding and moving the cutting tool. It slides along the bed and can be adjusted to control the depth and direction of the cuts. The carriage is a crucial component for precise and accurate machining.

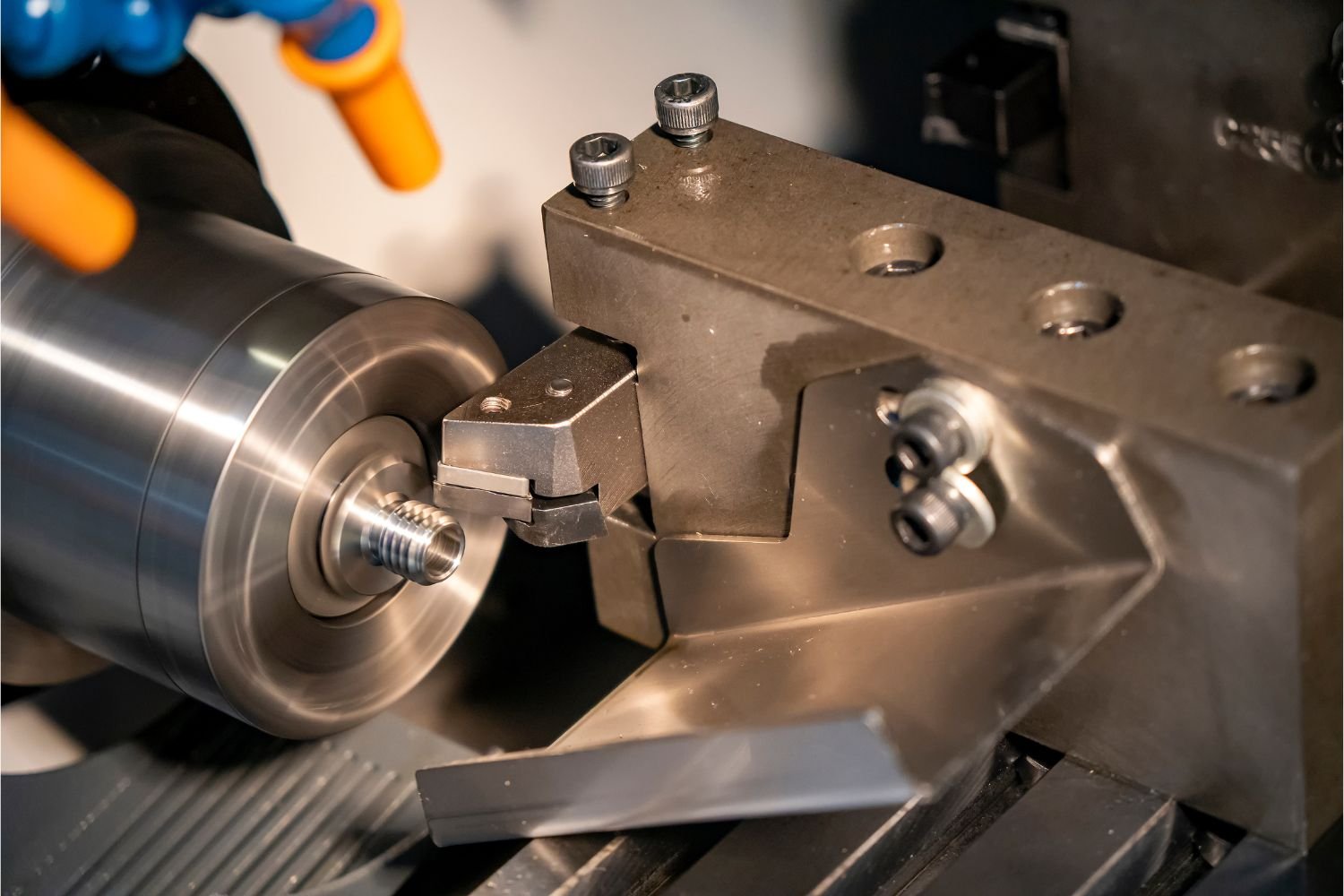

Toolpost

Located on top of the carriage, the toolpost holds and secures the cutting tool in place. It allows the machinist to easily change and position the tool, ensuring efficient and safe cutting.

Types of Metal Lathes

Engine Lathe

The engine lathe is the most common type of metal lathe and is widely used for general machining purposes. It is manually operated and offers various speed and feed adjustments. Engine lathes are perfect for a wide range of projects and are suitable for beginners and experienced machinists alike.

Bench Lathe

Smaller and more compact, bench lathes are designed for smaller workpieces and workshops with limited space. While they may have slightly reduced capabilities compared to engine lathes, they are portable and great for simple projects and hobbyists.

CNC Lathe

The CNC (Computer Numerical Control) lathe is a highly advanced and automated version of the metal lathe. It is controlled by computer programs that precisely dictate the tool’s movements, allowing for complex and intricate designs. CNC lathes are mainly used in industrial settings and require specialized programming skills.

Understanding the components and types of metal lathes is a crucial step in becoming proficient with these machines. With this knowledge, you can start to explore the world of metalworking and unleash your creativity to craft exceptional pieces.

Preparing the Metal Lathe

Before diving into the exciting world of metalworking on a lathe, it’s essential to prepare both the machine and the workpiece for optimal results. Here’s a step-by-step guide on how to get started:

Choosing the Right Workpiece

Selecting the right workpiece is the first crucial step in using a metal lathe. Ensure that the material you choose matches your project requirements and the lathe’s capabilities. Common workpiece materials include aluminum, steel, brass, and stainless steel. Remember to check the dimensions of the workpiece to ensure it fits within the lathe’s capacity.

Selecting the Appropriate Cutting Tools

Having the right cutting tools is essential for achieving precise and smooth cuts. There are various types of lathe cutting tools, such as turning tools, boring tools, and threading tools, each designed for specific machining operations. When choosing your cutting tools, consider the material you’re working with and the type of cuts you want to make.

Mounting and Securing the Workpiece

Properly mounting and securing the workpiece is crucial for safe and accurate machining. Begin by cleaning the workpiece and ensuring its surface is free from debris and dirt. Then, use appropriate fixtures, like chucks or collets, to secure the workpiece firmly in place on the lathe’s spindle. Double-check the alignment to avoid vibrations and mishaps during machining.

Adjusting Lathe Settings

Before you start turning, it’s essential to adjust the lathe settings to suit your project and workpiece material.

Speed Adjustments

The lathe’s rotational speed plays a vital role in achieving the desired finish and preventing tool wear. Slower speeds work well for larger workpieces and tougher materials, while faster speeds are suitable for smaller workpieces and softer materials. Refer to the lathe’s manual or online resources for recommended speed settings based on the material being machined.

Feed Rate Settings

The feed rate controls how fast the cutting tool moves along the workpiece. For roughing cuts, a higher feed rate is suitable, while finishing cuts require a slower feed rate for smoother results. Be cautious not to apply excessive pressure on the cutting tool to avoid damage to both the tool and the workpiece.

By carefully preparing the metal lathe and workpiece, you’re setting the stage for a successful and enjoyable metalworking experience. Paying attention to these preliminary steps will lay a solid foundation for mastering the art of using a metal lathe and creating remarkable pieces with confidence and precision.

How to Use a Metal Lathe

Now that you have prepared your metal lathe and workpiece, it’s time to explore the various machining operations you can perform. Understanding these operations will empower you to unleash your creativity and turn your workpiece into a masterpiece.

Turning Operations

Facing

Facing is one of the fundamental lathe operations and involves cutting the workpiece’s end to achieve a smooth and flat surface. It ensures the end is perpendicular to the lathe’s axis, creating a clean and even surface for subsequent machining operations.

Turning Between Centers

When you need to work on a long workpiece, turning between centers is the way to go. This method involves supporting the workpiece between two centers, allowing it to rotate freely while the cutting tool shapes its exterior. Turning between centers is ideal for achieving consistent and accurate results along the length of the workpiece.

Thread Cutting

Creating threads on a workpiece is essential for numerous projects. Whether you need to make a threaded bolt or nut, the metal lathe can handle it. Thread cutting requires precise tool positioning and depth adjustments to match the thread pitch you desire.

Boring and Reaming

Boring and reaming operations are used to enlarge existing holes in the workpiece. Boring cuts out the unwanted material, while reaming smoothens and refines the hole’s surface finish. These operations are commonly used to achieve tight tolerances and ensure a precise fit for moving parts.

Taper Turning

Taper turning allows you to create tapered surfaces, which are often seen in elements like cones or wedges. The process involves gradually adjusting the tool’s position as it moves along the workpiece, resulting in a gradual change in diameter.

Knurling

Knurling adds texture to the surface of a workpiece, providing better grip and a decorative touch. It is commonly used in tools and handles. The knurling tool is pressed against the rotating workpiece, creating diamond-shaped patterns on its surface.

Parting-off

Parting-off, also known as cutting off, is the process of cutting the workpiece to a specified length. This operation is often performed at the end of a project to separate the finished piece from the remaining material. Precision and care are necessary to avoid damage to the workpiece or the cutting tool.

Mastering these various operating techniques will open up a world of possibilities for your metalworking projects. As you gain experience, you’ll find that each operation brings unique challenges and rewards. So, let’s continue to explore the art of using a metal lathe and discover the endless potential it offers.

Best Practices and Tips for a Beginner Machinist

To achieve top-notch results and work efficiently with a metal lathe, it’s essential to follow some best practices and tips. These practices will not only enhance your machining skills but also contribute to a safe and enjoyable metalworking experience.

Proper Tool Handling and Positioning

The way you handle and position your cutting tools greatly affects the quality of your work. Always use tools that are sharp and in good condition to ensure clean and precise cuts. When mounting the tool in the toolpost, ensure it is secured tightly and at the correct height and angle. Avoid excessive tool overhang, as it can lead to unwanted vibrations and tool breakage.

Maintaining a Consistent Cutting Speed

Consistency in cutting speed is vital for achieving smooth and accurate results. Depending on the workpiece material and operation, choose an appropriate cutting speed and stick to it throughout the machining process. Inconsistent speeds can lead to uneven surfaces and tool wear, hampering the overall quality of your work.

Using Cutting Fluids for Optimal Results

Cutting fluids, such as oil or coolant, play a critical role in metal lathe operations. They help dissipate heat, reduce friction, and remove chips, resulting in improved surface finish and extended tool life. Apply cutting fluids generously to the cutting zone to keep both the workpiece and the cutting tool cool and lubricated.

Ensuring Workpiece and Tool are Properly Aligned

Proper alignment of the workpiece and cutting tool is key to achieving accurate and symmetrical cuts. Double-check that the workpiece is securely mounted and centered in the lathe. Ensure the tool is positioned at the correct height and aligned with the workpiece to avoid uneven cuts and excessive tool wear.

Minimizing Vibration and Chatter

Vibration and chatter can negatively impact your machining process, leading to poor surface finishes and potential tool breakage. To minimize these issues, ensure the lathe is securely anchored and placed on a level surface. Use the correct cutting speed and feed rate for the material being machined, and avoid excessive tool engagement to reduce the risk of chatter.

By incorporating these best practices and tips into your metal lathe operations, you’ll notice a significant improvement in the quality and efficiency of your work. Remember, practice makes perfect, so keep honing your skills and exploring new techniques to become a proficient metal lathe operator. With dedication and attention to detail, you’ll be creating exceptional metalwork pieces in no time.

Safety Guidelines

Safety should always be the top priority when using a metal lathe. The powerful nature of the machine and the sharp cutting tools demand careful attention and adherence to safety guidelines. By following these essential safety practices, you can ensure a secure and accident-free metalworking experience.

Personal Protective Equipment (PPE)

Wearing the appropriate Personal Protective Equipment (PPE) is vital to safeguard yourself from potential hazards. When operating a metal lathe, always wear safety glasses or a face shield to protect your eyes from flying debris. Additionally, wear ear protection to shield your ears from the noise generated during machining. Lathe operations can also produce fine metal chips, so wearing a shop apron, long-sleeved shirts, and closed-toe shoes is crucial to protect your skin and clothing.

Machine Safety Measures

Emergency Stop Procedures

Familiarize yourself with the location and operation of the emergency stop button on the metal lathe. In case of any unexpected situation or emergency, press the emergency stop button immediately to halt all machine operations. Practice this procedure until it becomes instinctive to react quickly and effectively during critical moments.

Chuck and Collet Safety

When mounting the workpiece on the lathe’s chuck or collet, ensure it is securely tightened and properly aligned. A loose or misaligned workpiece can become a hazardous projectile during machining. Always follow the lathe’s instructions for chuck or collet usage, and double-check the workpiece’s stability before starting any cutting operation.

Handling Sharp Tools and Chips

Sharp cutting tools can cause serious injuries if mishandled. Never attempt to touch or adjust the cutting tool while the lathe is running. Wait for the machine to come to a complete stop before making any adjustments or removing the tool. When removing chips from the cutting area, use a brush or a specialized chip removal tool rather than your hands to prevent cuts or injuries.

By prioritizing safety and following these guidelines, you can minimize the risk of accidents and injuries while operating a metal lathe. Remember to stay focused, alert, and take the necessary precautions at all times. Safe metalworking practices ensure that you can fully enjoy the rewarding experience of using a metal lathe while protecting your well-being.

Troubleshooting Common Issues

As with any machining process, using a metal lathe may present some common issues. However, armed with knowledge and a few troubleshooting techniques, you can quickly address these challenges and ensure smooth and successful metalworking.

Chatter Marks

Chatter marks are the undesirable wavy lines that appear on the surface of your workpiece. They result from vibrations between the cutting tool and the workpiece, often caused by improper tool positioning or excessive cutting forces. To tackle chatter marks, try the following:

- Check Tool Rigidity: Ensure that the cutting tool is securely fastened in the toolpost and that there is no excessive tool overhang.

- Reduce Tool Engagement: Opt for lighter cuts or decrease the depth of cut to lessen the cutting forces and vibrations.

- Check Workpiece Support: Verify that the workpiece is securely mounted and supported to minimize movement during machining.

Tool Breakage

Tool breakage can happen due to various reasons, such as using worn-out or incorrect tools, excessive tool engagement, or improper tool positioning. To prevent tool breakage, consider these steps:

- Use Proper Tools: Ensure you are using the correct type of cutting tool for the specific machining operation.

- Monitor Tool Condition: Regularly inspect the cutting tool for signs of wear and replace it when necessary.

- Optimize Cutting Parameters: Adjust cutting speed and feed rate to match the workpiece material and operation, reducing the risk of excessive tool wear and breakage.

Surface Finish Problems

Achieving the desired surface finish is essential for a successful metalworking project. Surface finish problems may include rough or uneven surfaces, poor surface texture, or excessive tool marks. To improve surface finish, try the following:

- Use Sharp Tools: Always use sharp cutting tools to ensure clean and smooth cuts.

- Optimize Speed and Feed: Adjust cutting speed and feed rate based on the workpiece material and machining operation for better surface finishes.

- Consider Cutting Fluids: Applying cutting fluids can enhance surface finish by reducing heat and friction during cutting.

Troubleshooting common issues may require some trial and error, but don’t be discouraged. Metalworking is a skill that improves with practice and experience. By paying attention to these troubleshooting techniques, you’ll be well-equipped to address challenges and create exceptional metalwork pieces. Remember, practice and perseverance are key to mastering the art of using a metal lathe.

Maintenance and Cleaning – Sharpen Tools and Keep Workspace Clear

Proper maintenance and regular cleaning are crucial to ensure your metal lathe operates at its best and delivers precise results. By following these maintenance practices, you can extend the machine’s lifespan and maintain the quality of your metalworking projects.

Regular Cleaning and Lubrication

Keeping your metal lathe clean is essential for its smooth operation. After each use, remove any metal chips, dust, or debris from the lathe’s components, including the bed, headstock, tailstock, and carriage. A brush or compressed air can be useful for this task. Remember to wear appropriate safety gear, like safety glasses and a dust mask, to protect yourself from dust and metal particles.

Lubrication is equally important to reduce friction and prevent wear. Refer to the manufacturer’s guidelines for the specific lubrication points on your lathe. Regularly apply the recommended lubricants to the moving parts, such as the lead screw and gears. Proper lubrication will not only ensure smoother operation but also contribute to the longevity of your machine.

Checking and Adjusting Alignment

Regularly checking and adjusting the alignment of your metal lathe is crucial for accurate machining. Misalignment can lead to uneven cuts and compromised precision. Follow these steps to check and adjust the alignment:

- Check the Bed: Use a precision level to ensure the lathe’s bed is level and horizontal.

- Tailstock Alignment: Check that the tailstock is aligned parallel to the lathe’s bed. Adjust the tailstock if necessary to achieve alignment.

- Carriage Alignment: Verify that the carriage moves smoothly along the bed and is correctly aligned. Make any necessary adjustments to achieve proper alignment.

Tool Maintenance

Maintaining your cutting tools is essential to achieve high-quality results and prevent accidents. Regularly inspect your cutting tools for signs of wear, such as chipping or dull edges. Replace worn-out tools promptly to avoid subpar cuts and reduce the risk of tool breakage.

Additionally, keep your cutting tools sharp. Sharpening can be done using a bench grinder or specialized sharpening tools. Always follow the correct sharpening angles and techniques recommended for your specific tools.

By incorporating regular maintenance and cleaning into your metal lathe routine, you’ll be able to enjoy consistent and accurate results in your metalworking projects. A well-maintained lathe not only enhances your craftsmanship but also ensures a safer and more enjoyable metalworking experience overall.

Advanced Techniques and Projects

Once you have gained confidence in using a metal lathe and have mastered the basics, it’s time to explore some advanced techniques and take on exciting projects. These challenging endeavors will further develop your metalworking skills and allow you to create impressive and functional pieces.

Knurling a Handle

Knurling is a decorative technique that also improves grip and enhances the appearance of a handle. To knurl a handle, follow these steps:

- Prepare the Handle: Choose a solid workpiece material for the handle, such as aluminum or steel. Mount it securely on the lathe.

- Position the Knurling Tool: Place the knurling tool on the lathe’s toolpost at the desired angle and height.

- Engage the Knurling Tool: Start the lathe and slowly engage the knurling tool into the workpiece’s surface. Apply consistent pressure to achieve the desired knurled pattern.

- Complete the Knurling: Move the knurling tool along the handle’s length to create a uniform knurled pattern. Use cutting fluids to ensure smooth cutting and preserve the knurling tool’s sharpness.

Creating a Threaded Bolt

Threading is an essential skill for making fasteners like bolts and screws. To create a threaded bolt, follow these steps:

- Choose the Workpiece: Select a suitable metal rod for the bolt, ensuring it matches the thread specifications you need.

- Set up the Lathe: Mount the workpiece between centers or using a chuck, ensuring it is secure and properly aligned with the lathe’s axis.

- Select the Thread Pitch: Choose the appropriate threading tool and set the lathe to the correct thread pitch.

- Engage the Threading Tool: Carefully engage the threading tool into the workpiece, ensuring it aligns with the lathe’s axis.

- Create the Threads: Slowly advance the threading tool along the workpiece, forming the threaded pattern. Pay attention to maintaining a constant feed rate and avoiding any sudden movements.

Turning a Simple Cylindrical Shape

While this may seem basic, turning a simple cylindrical shape can be a challenging exercise in achieving precision and consistency. To turn a cylindrical shape, follow these steps:

- Select the Workpiece: Choose a material suitable for your project and mount it securely on the lathe.

- Set Up the Lathe: Adjust the lathe settings, such as speed and feed rate, to match the workpiece material.

- Position the Cutting Tool: Position the cutting tool on the toolpost at the correct height and angle for the desired cut.

- Start Turning: Begin the turning process by engaging the cutting tool with the workpiece. Gradually move the cutting tool along the workpiece to shape it into a smooth cylindrical form.

- Check the Dimensions: Regularly measure the diameter and length of the cylindrical shape using calipers or a micrometer to ensure it matches your desired specifications.

By exploring these advanced techniques and projects, you will refine your metalworking skills and gain the confidence to take on more challenging and creative endeavors. The metal lathe offers endless opportunities for innovation and craftsmanship, allowing you to turn raw materials into intricate and functional masterpieces.

Frequently Asked Questions

What is a tool bit?

A tool bit is a hardened and shaped piece of steel used to cut or shape materials in machine tools.

What is a drill?

A drill is a rotating cutting tool that is used to create holes in materials.

What is a tool holder?

A tool holder is a device used to hold a cutting tool or a drill in a machine tool.

What does it mean to grind?

Grinding refers to the process of using an abrasive wheel or belt to shape or finish a workpiece by removing material.

What is a machine tool?

A machine tool is a tool that is used to shape, cut, or deform materials by rotating or moving them on multiple axes.

How do I operate the lathe?

To operate the lathe, you need to set the appropriate spindle speed, position the workpiece, and use the necessary cutting tools to shape or cut the material.

What is spindle speed?

Spindle speed refers to the rotational speed of the spindle or chuck of a lathe or any other machine tool.

What is the axis of the lathe?

The axis of the lathe refers to the imaginary line around which the lathe rotates and the workpiece is shaped or cut.

What is a machine shop?

A machine shop is a facility where various types of machine tools are used for manufacturing or repairing metal parts or components.

What is the end of the lathe bed?

The end of the lathe bed refers to the part of the lathe where the chuck or other attachments are located.