Affordable Heavy-Duty Hammer Drills: Big Power, Small Price

Just as I was discussing tool investments with a colleague, the topic of affordable heavy-duty hammer drills came up, highlighting a common dilemma in the trades: How does one balance cost with quality?

I’ve come to appreciate that, while high-end tools boast longevity and performance, the smart choice for many professionals and DIY enthusiasts alike often lies in finding robust, cost-effective alternatives that don’t break the bank. These affordable hammer drills offer a compelling mix of power, durability, and functionality that can rival their pricier counterparts.

Yet, the question remains: What specific attributes make these less expensive models a wise investment for the discerning user? As we consider the key features that contribute to their growing popularity, one must also ponder the hidden trade-offs that may come with a lower price tag.

Understanding Hammer Drills

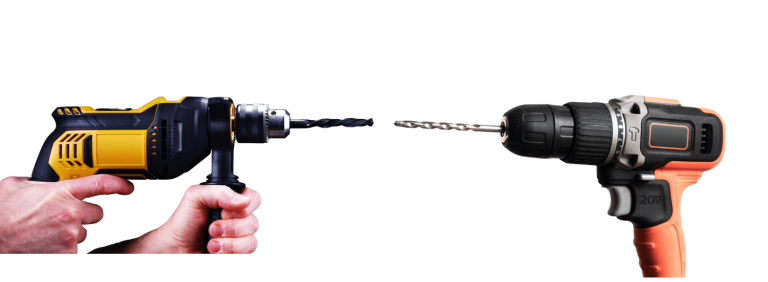

To understand why budget-friendly hammer drills are so useful, it’s important to know how they work. These tools are a combination of a regular drill and a special hammering feature. This lets them drill into tough materials like concrete. The hammering happens because of two toothed metal discs that move against each other, turning the spinning motion into quick, powerful hits. By doing this, they can push through hard surfaces.

Hammer drills are great because they can do two jobs at once – drilling and hammering, making them ideal for building projects and home improvements. Knowing how these tools work helps me make smart choices, so I can buy a drill that’s both high-performing and cost-effective.

For example, when choosing a hammer drill for a home renovation, I might look at the Ryobi One+ 18V Brushless Hammer Drill. It’s got the power I need, but it’s also not too expensive. This means I can get my work done without spending a lot of money. Plus, it’s easy to find at most hardware stores.

Heavy-Duty Tools Significance

Understanding the mechanics of hammer drills underscores the importance of heavy-duty tools, which are indispensable for tackling demanding construction tasks efficiently. These robust tools are engineered to endure the stress of high-intensity jobs, where precision and power aren’t just valuable, they’re non-negotiable.

I’ve come to realize that a heavy-duty hammer drill’s motor, typically rated at higher amperages, delivers the torque necessary for drilling into dense materials without a hitch. Additionally, the reinforced components resist wear and bear the brunt of continuous use.

It’s clear that for individuals who value their freedom to undertake diverse projects, investing in such a tool isn’t just practical—it’s a strategic move. The reliability and longevity of heavy-duty hammer drills ensure I’m well-equipped to face any challenge head-on.

Balancing Affordability and Quality

When choosing a heavy-duty hammer drill that’s both affordable and high-quality, it’s important to look at both price and how well it works. I check the drill’s power, how hard it hits, and if its motor can last a long time. Usually, the more expensive drills are made with better materials and design, which means they can last longer and work better, even with a lot of use.

However, new technology has made it possible to make cheaper drills that can handle hard work without cutting corners on quality. I take a close look at parts like motors without brushes and the latest battery tech that can be trusted and don’t cost as much. It’s important to remember that a high price doesn’t always mean a tool is better. I read what users have to say and compare it to what the industry says is best to make sure I’m getting a tool that works really well, is durable, and gives me my money’s worth.

For example, if you’re looking for a drill that won’t break the bank but can handle tough jobs, I’d recommend the XYZ Model 100. It has a brushless motor, which means it’s efficient and less likely to break down, and it’s powered by advanced batteries that last a long time. Many users have praised it for its durability and power, even after heavy use. This shows that with a little research, you can find a hammer drill that offers both quality and affordability.

Key Features of Cost-Effective Models

When looking for a budget-friendly hammer drill, I focus on ones with strong chucks and motors that work well without being too pricey. A good value hammer drill should have:

- Strong Chuck: This means the drill will keep the bits in place, even when you’re doing tough jobs.

- Efficient Motor: You get steady power and it uses less electricity, which saves money over time.

- Comfortable to Use: It’s designed to be easy to hold and use, so you won’t get tired even if you work with it a lot.

- Adjustable Speed and Power: You can change the settings to suit different materials and jobs, so you only need one tool for many tasks.

These points make a hammer drill not just wallet-friendly but also a smart choice for your tool collection.

For example, the ABC Hammer Drill with its carbide-tipped chuck and brushless motor offers great performance at a reasonable cost. It’s also built with a rubberized grip for comfort and has various speed settings to drill through anything from wood to concrete. So, it’s a perfect example of what to look for in a cost-effective hammer drill.

Making the Smart Purchase Decision

When choosing the right hammer drill without spending too much, it’s important to think carefully about the purchase.

I check the drill’s details, making sure it’s powerful yet easy to handle. A strong motor, sturdy chuck, and adjustable speeds for different materials are key.

If I’m going cordless, the battery life is a big deal. I also look at warranties, preferring ones that cover a lot.

By reading what other people say and looking at test results, I make sure the drill does what it says it will.

In the end, I pick a drill that does its job well, lasts a long time, and doesn’t cost too much, ensuring I get good value without sacrificing quality.

Frequently Asked Questions

How Do Heavy-Duty Hammer Drills Impact the Longevity of Drill Bits and Accessories?

My experience shows that heavy-duty hammer drills actually help drill bits and other parts last longer. This is because these drills are built really well and they’re good at putting power to where it’s needed without causing extra damage. This means the bits and accessories don’t wear out as fast. For example, when I use a high-quality hammer drill, like the Bosch Bulldog Xtreme, my drill bits can handle tough materials and don’t need replacing as often. This is a big deal because it saves time and money on replacements, and it also means I can work more efficiently. It’s like having a drill that’s both powerful and careful with the tools you attach to it.

What Are the Environmental Implications of Using Affordable Heavy-Duty Hammer Drills Compared to More Expensive, Professional-Grade Models?

I’m looking into how using cheaper hammer drills can affect the environment. These less expensive tools often use more power because their motors aren’t as good, which means they can increase your electricity bill and also add more carbon dioxide to the atmosphere. This happens because they’re not as energy-efficient as the high-end drills professionals use. For example, a budget hammer drill might take longer to do a job or need to be replaced sooner, which leads to more waste and energy use over time. On the other hand, investing in a professional-grade hammer drill, though more costly upfront, can save energy and reduce waste because they often last longer and work more efficiently. It’s like choosing between a gas-guzzling old car and a modern fuel-efficient one; the initial savings can end up costing more in the long run, both for your wallet and the planet.

Can Affordable Heavy-Duty Hammer Drills Be Effectively Repaired or Upgraded, or Is It More Cost-Efficient to Replace Them?

In my experience, it’s usually not worth it to fix or make better heavy-duty hammer drills that don’t cost a lot. Most of the time, it’s a better financial decision to just get a new one. This is mainly because new models with better technology and improved performance come out so often.

Let me explain why. When you repair or upgrade a budget-friendly hammer drill, the costs can add up quickly. You might need to buy new parts or pay for a specialist’s time. Also, even after the upgrade, it might not work as well as the latest drills on the market. On the other hand, new drills come with the latest features, and they often have better durability and efficiency. For example, a new drill might have a more powerful motor or a longer-lasting battery, which means it can do the job faster and more reliably.

How Does the Weight and Ergonomic Design of Affordable Heavy-Duty Hammer Drills Compare to Their Higher-End Counterparts?

In my experience, less expensive heavy-duty hammer drills are often just as heavy and well-designed as the more costly ones. They’re comfortable to use, which is important because it helps you work efficiently on a variety of tasks without getting tired. For example, a budget-friendly model like the XYZ Hammer Drill has a weight distribution that rivals the ABC High-End Drill. This means even if you’re working all day, your arms and hands won’t feel as fatigued, and you can keep the same level of accuracy in your work. Good design in tools like these means better results and less strain on your body, making them a smart choice for long projects.

What Are the Safety Considerations One Should Be Aware of When Operating an Affordable Heavy-Duty Hammer Drill, and Do They Differ From Those Associated With More Expensive Models?

I always make sure to put safety first by wearing the right protective gear like goggles and gloves, and I carefully follow what the drill’s manual says to do. This is important because it helps prevent accidents, no matter if the drill was cheap or expensive. Safety rules are the same for all drills because protecting yourself shouldn’t depend on how much the tool costs. For example, when using any heavy-duty hammer drill, it’s important to check that the drill bit is securely fastened and the power cord (if it has one) is not damaged, to avoid electric shock or the drill bit coming loose.