Best Benchtop Jointer to Get the Perfect Union

When it comes to woodworking, having the right tools becomes essential.

To create a truly spectacular piece of furniture, you’ll want access to the best resources – from saws and drills to jointers and presses.

Among these essential items is one of woodworking’s finest achievements: the benchtop jointer.

More portable, affordable, and storable than bigger floor models, benchtop jointers allow amateur and master craftsmen to turn rough-cut lumber into smooth, finished boards with unparalleled efficiency.

But with so many models on the market today, how can you find the ideal benchtop jointer for your needs?

In this article, we’ll explore your options and provide tips on making an informed decision that will take your craftsmanship level up a notch!

Want something that’ll pull double duty? Check out our picks for the best jointer-planer combos.

Need something bigger? Check out our picks for the best jointer.

How We Choose the Best Benchtop Jointers

Choosing the best benchtop jointers can be difficult with all of the different brands and features on the market.

How do you know if you’re getting a quality product?

Is it worth spending more for a better machine?

Will you even use all of the features on the more expensive model?

We’ve made it easy for you.

After reading through thousands of reviews and comparing specs, we’ve come up with a list of the best benchtop jointers for any budget or need.

Whether you’re looking for a basic machine or one with extra bells and whistles, we’ve got you covered.

Overall Winner – Best Benchtop Jointer

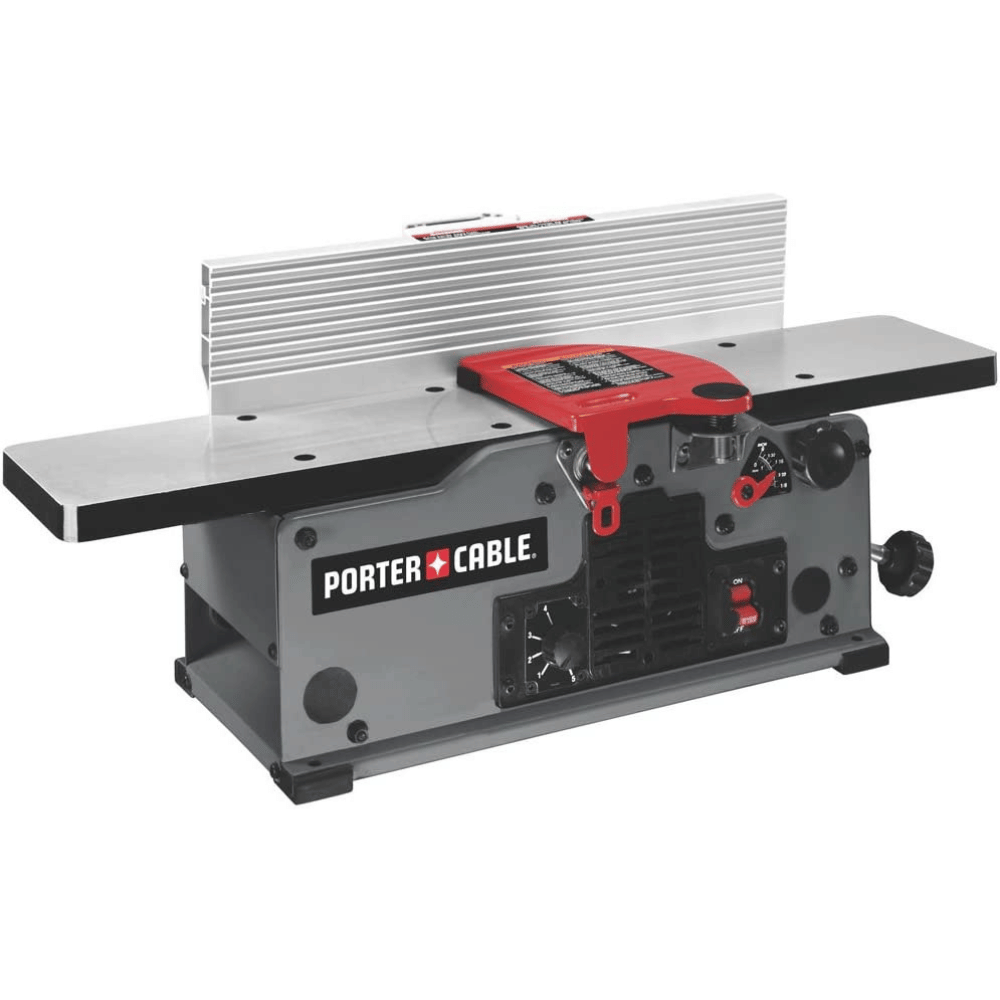

PORTER-CABLE Benchtop Jointer, 6-Inch Variable Speed (PC160JT)

Key Features

- 10 Amp motor, 6-inch table

- Variable speed range from 6,000 to 11,000 RPM

- Straight knife cutterhead

Why It’s a Great Choice

When you’re looking for a benchtop jointer capable of tackling the toughest projects, turn to this PORTER-CABLE Benchtop Jointer.

For novices and experienced woodworkers alike, this model is the perfect choice for precision cutting and creating smooth, flat surfaces for boards and other pieces of wood.

With a powerful motor and built-in cutter head lock for knife replacement and adjustment, this jointer has everything you need to get the job done correctly no matter what project you’re working on.

It also comes with an extra large table to provide ample work support for an accurate cut as well as surfacing stock up to a full 6″ wide.

The top features an extra-long table and center-mounted fence that ensures consistency during even the most complex projects.

Whether it’s a simple project or something more complex, you can always trust the PORTER-CABLE Benchtop Jointer to deliver professional results every time.

Best Benchtop Jointer for a Beginner

CRAFTSMAN Benchtop Jointer, 10-Amp (CMEW020)

Key Features

- 10 Amp motor, 6-inch table

- Variable speed from 6,000 to 11,000 RPM

- 12,000 – 22,000 cuts per minute

Why It’s a Great Choice

If you’re looking for a reliable, efficient jointer for your next woodworking project, then look no further than the CRAFTSMAN Benchtop Jointer.

This top-quality benchtop jointer is packed with smart features that make it ideal for woodworkers of all skill levels.

Its two-knife cutter head and jackscrew knife leveling arrangement allow you to effortlessly swap out knives and make sure they’re perfectly aligned before each cut.

Meanwhile, its range of 6, 000 to 11,000 RPM lets you find the best speed for whatever material you’re cutting.

And each cut gets added support from the center-mounted fence which ensures accurate edge jointing each time.

So if you want an easy-to-use benchtop jointer that can stand up to any task, go with the outstanding CRAFTSMAN Jointer.

Best Benchtop Jointer on a Budget

WEN 10-Amp 6-Inch Spiral Benchtop Jointer (JT630H)

Key Features

- 10 Amp motor, 6-inch table

- Variable speed up to 12,000 RPM

- Spiral cutter head – 12 staggered HSS blades

Why It’s a Great Choice

Are you a woodworker looking for the perfect jointer?

Look no further than the WEN 10-Amp 6-Inch Spiral Benchtop Jointer!

This jointer is designed with superior engineering, giving you incredible power and accuracy in just one package.

To give you an unbeatable jointing experience, the WEN 6-Inch Spiral Benchtop Jointer comes with a spiral cutter head equipped with 12 high-speed steel blades.

With its powerful 10 Amp motor, this jointer can spin the cutter head up to 12,000 times per minute to achieve a flawless finish on both hard and soft woods.

To ensure maximum precision, its infeed table can take 0 to 1/8 inch off material per pass – trust in the reliable scale to accurately measure your cutting depth for perfect results.

The WEN 6-Inch Spiral Benchtop Jointer’s 30 by 6-inch table offers plenty of room for larger projects and will simplify alignments across multiple pieces of wood.

It can also bevel up to 45 degrees for angled cuts along board faces.

Plus, it features two safety push blocks and an intuitive spring-loaded blade guard that helps protect against accidental injuries – it’ll only expose limited sections of the cutter head when in use.

Don’t miss out on achieving professional results every time: get yours today and discover why the WEN 6-Inch Spiral Benchtop Jointer has been so highly rated!

Best 8-Inch Benchtop Jointer

RIKON Power Tools 8-Inch Benchtop Jointer (20-800H)

Key Features

- 10 Amp motor, 8-inch table

- Variable speed up to 20,000 RPM

- 6-row helical-style cutter head with 16 two-sided carbide inserts

Why It’s a Great Choice

Woodworkers looking for the best cutting performance need only look as far as RIKON Power Tools’ 8-Inch Benchtop Jointer.

This jointer features a helical-style cutterhead with 16 two-sided carbide inserts that deliver quick, clean, and effortless cuts.

You’ll also appreciate the large 19-3/4″ x 4-3/8″ aluminum fence and easy-read depth scale that simplifies adjustments on the fly.

With a full table size of 30-1/2″ x 8-3/16″ extending to 51-1/2″ x 8-3/16″, this topnotch 8” jointer won’t leave you wanting more space while taking on your toughest projects.

Ensure accuracy and reliability every time with RIKON’s unique spring-loaded safety guard and built-in front switch to quickly shut off power when not in use.

Don’t wait around any longer; invest in your next major tool acquisition today with RIKON’s 8-Inch Benchtop Jointer.

Best Benchtop Jointer for Large Projects

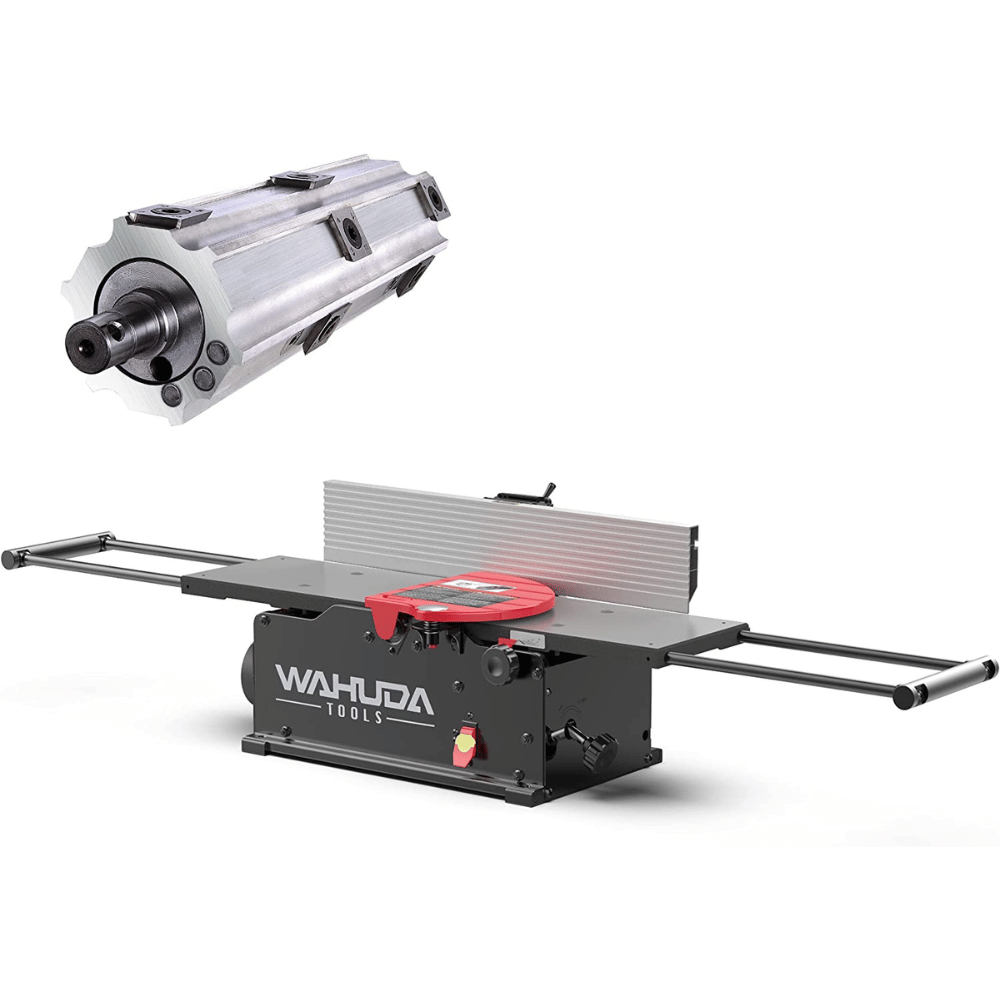

Wahuda Tools 10-inch Benchtop Wood Jointer (50110CC-WHD)

Key Features

- 12 Amp motor, 10-inch table

- Single speed – 12,000 RPM

- Spiral cutter head

Why It’s a Great Choice

For woodworkers who are serious about producing perfect, consistent results every time, the Wahuda Tools 10-inch Benchtop Wood Jointer is the ideal tool.

Using a cast iron surface and extension supports for the infeed and outfeed tables, you’ll be able to smooth away rough surfaces that can ruin an entire project.

What puts this jointer above the rest are its spiral Cutterhead blades developed with advanced sharpness that traditional straight knife blades just can’t offer.

The four sides of carbide insert tips ensure smoother cuts as well as smaller shavings—an aspect critical to achieving professional-grade results.

For craftspeople who require nothing less than perfection in their work, Wahuda Tools 10-inch Benchtop Wood Jointer gives you the reliable performance that your projects demand.

Get precisely machined surfaces and perfectly jointed edges reliably each time you use this top-of-the-line product from the experts at Wahuda Tools.

Buyer’s Guide to the Best Benchtop Jointers

People are often overwhelmed when shopping for a benchtop jointer because there are so many different factors to consider.

It’s hard to know which benchtop jointer is the best for your needs, and even harder to figure out which features you should be looking for.

We’ve created this FAQ page to help you understand the basics of benchtop jointers and figure out which model is the best fit for your workshop.

What is a benchtop jointer?

A benchtop jointer is a woodworking tool designed to help create flat, smooth surfaces on boards and other pieces of wood. This machine consists of a flat table and a rotating cutter head with sharp knives or blades. The board is fed through the machine and the rotating blades shave off the high points on the board to create a flat, even surface.

Benchtop jointers are typically smaller and more affordable than larger, stationary jointers, making them a popular choice for hobbyists and small woodworking shops. They are designed to be mounted on a workbench or table, which means they take up less space and are easier to move around when necessary.

While a benchtop jointer can handle most basic jointing tasks, it may not be able to handle larger, thicker boards. Additionally, some models may require more frequent maintenance than larger jointers.

Overall, a benchtop jointer is a useful tool for any woodworker who needs to create flat, smooth surfaces on their projects. Whether you’re a beginner or a seasoned pro, a benchtop jointer can help you achieve the results you’re looking for.

How does a benchtop jointer work?

A benchtop jointer is a woodworking tool designed to flatten, straighten, and smooth rough lumber. It works by removing small amounts of wood from the surface of a board or plank, using a rotating cutter head equipped with sharp blades.

The process starts with the board being placed onto the infeed table, which is the flat surface located at the beginning of the jointer. The infeed table has an adjustable height, allowing the operator to set the depth of cut for the blades. The operator then turns on the motor, causing the cutter head to rotate at high speed.

As the board is fed into the machine, it passes over the rotating blades, which shave off the high points and remove any twists, warps, or bows in the board. The newly flattened surface then moves over the outfeed table, which is located at the end of the jointer, creating a smooth, even surface on the board.

Benchtop jointers typically have a maximum cutting width of 6 inches, which means that boards wider than 6 inches may need to be jointed in multiple passes. Some benchtop jointers also come with a fence, which helps to keep the board straight and at a consistent angle as it moves through the jointer.

In summary, a benchtop jointer works by removing small amounts of wood from the surface of a board, creating a flat, smooth surface. By using this tool, woodworkers can transform rough, uneven boards into straight, consistent pieces of lumber that are easier to work with and more aesthetically pleasing.

What type of material can I use with a benchtop jointer?

A benchtop jointer is a versatile woodworking tool that can be used with a variety of materials, including different types of wood and some non-wood materials. Here are some materials that can be used with a benchtop jointer:

- Hardwoods: A benchtop jointer is ideal for use with hardwoods, such as oak, maple, cherry, and walnut. Hardwoods can be difficult to work with due to their density and hardness, but a jointer can make them more manageable by flattening and smoothing the surface.

- Softwoods: Softwoods, such as pine, cedar, and fir, can also be used with a benchtop jointer. Jointing softwoods can help to create a smooth surface and reduce the risk of splintering or tear-out when sawing or routing.

- Composite Materials: Some composite materials, such as MDF (medium-density fiberboard) and particleboard, can also be used with a benchtop jointer. However, it’s important to note that these materials may dull the blades faster than wood, so it’s important to take extra care when joining them.

- Plastic and Acrylic: Certain types of plastic and acrylic can be jointed using a benchtop jointer. However, it’s important to use a slower feed rate and take extra care to avoid melting or warping the material.

- Metal: While a benchtop jointer is primarily designed for woodworking, some models may be able to joint soft metals, such as aluminum and brass. However, this should only be done with specialized blades and caution, as metalworking can be dangerous.

In summary, a benchtop jointer can be used with a variety of materials, including different types of wood, composite materials, plastic, acrylic, and some soft metals. However, it’s important to use caution and take extra care when jointing non-wood materials, and to make sure that the blades are appropriate for the material being used.

What are the main benefits of using a benchtop jointer?

A benchtop jointer is a versatile and essential tool for any woodworker who wants to achieve precision and accuracy in their work. Here are some of the benefits of using a benchtop jointer in woodworking:

- Flattens and Straightens Boards: A benchtop jointer allows woodworkers to flatten and straighten boards, making them easier to work with and improving the overall quality of the finished product. By removing any twists, warps, or bows in the wood, a jointer creates a flat, even surface that is essential for many woodworking projects.

- Increases Accuracy: Jointing a board ensures that the edges are perfectly square and straight, which is crucial when making furniture, cabinetry, or other projects that require precise measurements. A jointed board is also easier to glue up and creates a stronger joint.

- Saves Time: By using a benchtop jointer, woodworkers can save time and effort in the later stages of their projects. By starting with a flat, straight board, they can avoid the need for excessive sanding or planing, and reduce the risk of mistakes or errors that can occur when working with uneven or warped lumber.

- Improves Safety: A benchtop jointer can also improve safety in the workshop. Removing the high points and irregularities in the wood reduces the risk of kickbacks and other accidents that can occur when working with uneven or unstable lumber.

- Affordable and Space-Saving: A benchtop jointer is typically more affordable and takes up less space than larger, stationary jointers. This makes it a popular choice for hobbyists and small woodworking shops.

In summary, a benchtop jointer is a valuable tool for any woodworker who wants to achieve precision, accuracy, and efficiency in their work. Whether you’re a beginner or a seasoned pro, a benchtop jointer can help you produce high-quality, professional-looking results.

What kind of cutter heads are available for benchtop jointers?

Benchtop jointers typically use one of two types of cutter heads: the spiral cutter head or the straight knife cutter head. Here’s an overview of each type:

- Spiral Cutter Head: A spiral cutter head is made up of multiple small, carbide-tipped blades arranged in a helical pattern. This design allows the blades to make a slicing cut, which reduces tear-out and creates a smoother surface. Spiral cutter heads are known for their durability, and they tend to stay sharp longer than straight knife cutter heads. They are also quieter and produce less vibration than straight knife cutter heads.

- Straight Knife Cutter Head: A straight knife cutter head uses two or three blades that are set at an angle to the cutter head. This design creates a shearing cut, which can result in a very smooth surface. However, straight knife cutter heads tend to be louder and produce more vibration than spiral cutter heads. They also require more frequent sharpening, which can be time-consuming and expensive.

In addition to the type of cutter head, benchtop jointers may also vary in the number of blades they use. Some jointers have two blades, while others have three or four. More blades can result in a smoother cut, but can also increase the cost and maintenance requirements of the jointer.

Overall, both spiral and straight knife cutter heads have their advantages and disadvantages, and the choice will depend on your personal preferences and the specific needs of your woodworking projects. Some benchtop jointers may offer the option to switch between different types of cutter heads, which can be a useful feature if you plan to work with a variety of materials or need to achieve different finishes.

Are there any safety concerns associated with using a benchtop jointer?

Yes, there are several safety concerns associated with using a benchtop jointer, as with any power tool. Here are some of the most important safety considerations to keep in mind:

- Blade Contact: The blades on a jointer are sharp and can cause serious injury if they come into contact with your fingers or other body parts. Always keep your hands and fingers away from the blades and use a push stick or push block to feed the material through the jointer.

- Kickback: Kickback can occur when a piece of material is suddenly thrown back towards the operator, often with great force. To avoid kickback, always use a flat and straight board and make sure the infeed and outfeed tables are level.

- Dust and Debris: Jointing can produce a lot of dust and debris, which can be hazardous to your health if inhaled. Always wear a dust mask or respirator and use a dust collection system or shop vacuum to capture dust and debris.

- Electrical Hazards: Always make sure the jointer is properly grounded and that the electrical cords are in good condition. Never use a jointer in wet conditions or near flammable materials.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including eye protection, ear protection, and close-fitting clothing. Loose clothing or jewelry can get caught in the jointer and cause injury.

- Maintenance: Regular maintenance is important to keep the jointer functioning properly and reduce the risk of injury. Make sure the blades are sharp and properly aligned, and that all safety guards and shields are in place and functioning correctly.

In summary, using a benchtop jointer requires strict adherence to safety protocols and precautions to prevent injury. Always follow the manufacturer’s instructions and use common sense when operating the jointer. Remember, safety should always be your top priority when working with any power tool.

How do I choose the right size and type of benchtop jointer for my needs?

Here are some factors to consider when selecting a benchtop jointer:

- Size: The size of the jointer refers to the width of the cutting bed, which determines the maximum width of the board that can be jointed. Benchtop jointers typically range in size from 6 to 10 inches. If you mainly work with smaller pieces of wood, a 6-inch jointer may be sufficient. However, if you frequently work with larger boards, you may want to consider an 8-inch or 10-inch jointer.

- Cutter Head: As mentioned earlier, there are two types of cutter heads – spiral and straight knife – and each has its advantages and disadvantages. Consider the type of material you’ll be working with and the finish you want to achieve when selecting a cutter head.

- Blade Count: The number of blades on the cutter head can also affect the quality of the finish. A jointer with more blades will generally produce a smoother finish, but will also be more expensive.

- Power: The motor power of a benchtop jointer determines how much material it can handle and how quickly it can work. A more powerful motor can handle larger and harder materials and will generally work faster.

- Brand and Price: Consider purchasing from reputable brands with positive customer reviews. Also, the price of benchtop jointers can vary greatly, so make sure to have a budget in mind before making a purchase.

- Space: Finally, consider the space you have available in your workshop. Benchtop jointers are designed to be portable and take up less space but still require a decent amount of space to operate safely.

In summary, choosing the right size and type of benchtop jointer requires considering your specific needs and preferences. Take your time to research the different options available and consider the factors outlined above to make an informed decision.

Choosing the Best Benchtop Jointer for You

The decision is yours – but remember, when you’re looking for a benchtop jointer there are many great options out there.

We’ve done the research and have narrowed it down to our top picks in this article.

So, whether you’re a professional woodworker or just a woodworking hobbyist, any of these choices will give you the surface planing power needed for your projects.

To save yourself time and energy, click the links to check the prices on Amazon and order your favorite now!

Have confidence that you’ll be getting the best surface finish possible on your woodworking project and enjoy years of satisfaction knowing that the power tool you choose will last long into your future.

Let us know how well they worked out for you!